All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

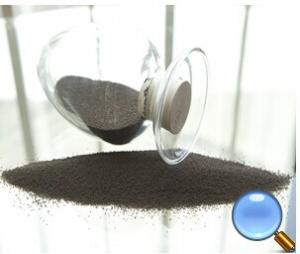

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do monolithic refractories perform in heat exchanger applications?

Monolithic refractories perform exceptionally well in heat exchanger applications due to their high thermal conductivity, excellent resistance to thermal shock, and ability to withstand extreme temperatures. They provide efficient heat transfer, minimize energy losses, and offer superior durability, making them ideal for use in heat exchangers.

What are the safety considerations when working with monolithic refractories?

Some safety considerations when working with monolithic refractories include wearing appropriate personal protective equipment such as gloves, safety glasses, and respiratory protection to prevent skin and eye irritation, as well as inhalation of dust particles. It is important to handle these materials carefully to avoid injury from sharp edges or falling objects. Additionally, proper ventilation should be maintained to minimize exposure to harmful fumes or dust. Regular inspections and maintenance of equipment and tools used in working with monolithic refractories are also crucial to ensure safe handling and prevent accidents.

How are monolithic refractories tested for quality control?

Monolithic refractories are tested for quality control through various methods including visual inspection, physical properties testing, and performance evaluation. Visual inspection involves checking for any cracks, surface defects, or inconsistencies in the material. Physical properties testing involves measuring parameters like density, porosity, thermal conductivity, and compressive strength to ensure they meet the required specifications. Additionally, performance evaluation is conducted by subjecting the refractories to extreme conditions like high temperatures and chemical exposure to assess their resistance and durability. These comprehensive testing methods ensure the quality and reliability of monolithic refractories.

Can monolithic refractories be used in kilns and furnaces?

Yes, monolithic refractories can be used in kilns and furnaces. Monolithic refractories are a type of refractory material that can be shaped and installed in various applications, including kilns and furnaces. They are typically used to line the interior of these high-temperature environments, providing thermal insulation and protection against chemical reactions and physical wear. Monolithic refractories offer advantages such as ease of installation, high thermal conductivity, and resistance to thermal shock, making them suitable for use in kilns and furnaces.

How do monolithic refractories handle slag attack?

Monolithic refractories are able to handle slag attack effectively due to their strong resistance against chemical erosion and thermal shock. These refractories have a dense and homogeneous structure, which prevents the penetration of slag into their matrix. Additionally, their high refractoriness and thermal conductivity help in dissipating heat and reducing the impact of slag attack. Overall, monolithic refractories offer excellent protection against slag attack, making them suitable for various high-temperature applications.

Wholesale Monolithic Refractories from supplier in Latvia

Our team of experts is dedicated to providing top-notch customer service and technical assistance to help you find the best Monolithic Refractories solutions for your specific requirements. Whether you are in need of refractory materials for industrial applications, furnaces, or kilns, we have the expertise and resources to meet your needs.

We understand the importance of timely delivery and competitive pricing, which is why we work closely with our network of suppliers to ensure that you receive the highest quality products at the most competitive prices. Our goal is to establish long-term partnerships with our customers, providing reliable and cost-effective solutions for their refractory needs.

In addition to our sales and procurement services, we also offer technical support to assist you in choosing the right refractory products for your projects. Our team of experts can provide guidance on product selection, installation techniques, and maintenance to ensure optimal performance and longevity of your refractory materials.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and developments, ensuring that we can provide the most innovative and efficient solutions to our customers in Latvia.

Whether you are a small business or a large industrial company, we are committed to delivering exceptional customer service and meeting your Monolithic Refractories needs in Latvia. Contact us today for sales, quotations, and technical support.

We understand the importance of timely delivery and competitive pricing, which is why we work closely with our network of suppliers to ensure that you receive the highest quality products at the most competitive prices. Our goal is to establish long-term partnerships with our customers, providing reliable and cost-effective solutions for their refractory needs.

In addition to our sales and procurement services, we also offer technical support to assist you in choosing the right refractory products for your projects. Our team of experts can provide guidance on product selection, installation techniques, and maintenance to ensure optimal performance and longevity of your refractory materials.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to stay at the forefront of industry trends and developments, ensuring that we can provide the most innovative and efficient solutions to our customers in Latvia.

Whether you are a small business or a large industrial company, we are committed to delivering exceptional customer service and meeting your Monolithic Refractories needs in Latvia. Contact us today for sales, quotations, and technical support.

Hot Search

- Monolithic Refractories in Czech Republic

- Ceramic Fiber Products in Kyrgyzstan

- Refractory Bricks in Dominican

- Raw Materials For Refractory in Malawi

- Refractory Bricks in Timor Leste

- Monolithic Refractories in Madagascar

- Monolithic Refractories in Ukraine

- Monolithic Refractories in Australia

- Ceramic Fiber Products in Belarus

- Raw Materials For Refractory in Ghana