All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the design principles for steel pipes used in high-pressure hydraulic systems in industrial machinery?

The design principles for steel pipes used in high-pressure hydraulic systems in industrial machinery include factors such as material strength, wall thickness, and corrosion resistance. These pipes need to be able to withstand the high pressures generated by hydraulic systems, so they are typically made of high-strength steel to ensure structural integrity. Additionally, the wall thickness of the pipes is carefully determined to prevent any potential leaks or failures. Corrosion resistance is also crucial to maintain the longevity and reliability of the pipes, as hydraulic systems often involve the use of various fluids that can be corrosive.

How are steel pipes integrated into the aerospace industry for aircraft landing gear and flight control systems?

Steel pipes are integrated into the aerospace industry for aircraft landing gear and flight control systems as they provide strength, durability, and resistance to high pressure and temperature. These pipes are used to carry hydraulic fluids that power landing gear systems and control surfaces, ensuring smooth and reliable operation during takeoff, landing, and in-flight maneuvers. Additionally, steel pipes are also utilized in the construction of structural components, offering crucial support and stability to the aircraft's landing gear and flight control systems.

What is the significance of ultrasonic testing in the detection of defects in steel pipes?

Ultrasonic testing is significant in the detection of defects in steel pipes because it allows for non-destructive evaluation. By using high-frequency sound waves, this testing method can accurately identify internal and external defects in the pipes, such as cracks, corrosion, and thickness variations. This helps ensure the integrity and reliability of the pipes, preventing potential failures and minimizing the risks of leaks or structural collapses. Ultrasonic testing also allows for early detection of defects, enabling timely maintenance and repair, thus extending the lifespan of the pipes and reducing overall costs.

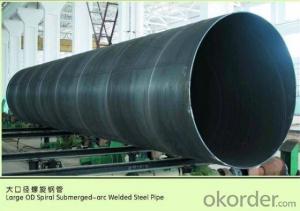

What is the difference between ERW and SAW steel pipes?

ERW (Electric Resistance Welded) and SAW (Submerged Arc Welded) steel pipes are two common types of welded steel pipes. The key difference between them lies in the welding process.

ERW pipes are created by passing a high-frequency electrical current through the edges of a steel strip or coil, melting the edges together to form a seam. This process is relatively quick and cost-effective, resulting in pipes with a smooth and uniform surface. ERW pipes are commonly used for low-pressure applications such as water and gas transportation, as well as structural and mechanical purposes.

On the other hand, SAW pipes are manufactured by submerging the steel plate or coil in a granular flux, which generates heat and forms a welding arc between the electrode and the steel. This continuous welding process produces a deep penetration weld, resulting in a strong and sturdy pipe. SAW pipes are typically used for high-pressure applications such as oil and gas transmission, as well as in heavy-duty industries like construction and infrastructure.

In summary, the main difference between ERW and SAW steel pipes lies in the welding technique used, which ultimately determines their respective applications and performance characteristics.

Wholesale Steel Pipes from supplier in Nauru

Our team of experts is well-versed in the various applications and specifications of Steel Pipes, ensuring that we can provide tailored solutions to meet your specific requirements. Whether you need Steel Pipes for construction, infrastructure development, oil and gas pipelines, or any other industry, we have the knowledge and resources to deliver high-quality products.

When it comes to pricing, we understand the importance of competitive rates without compromising on quality. Our strong partnerships with manufacturers allow us to negotiate favorable prices, ensuring that you get the best value for your investment. We also offer flexible payment options to accommodate your budget.

Technical assistance is another crucial aspect of our services. Our experienced engineers and technicians are available to provide guidance and support throughout your project, from the selection of the appropriate Steel Pipes to installation and maintenance. We stay updated with the latest industry standards and regulations to ensure that our solutions comply with all requirements.

Being affiliated with CNBM, a Fortune Global 500 company, gives us access to a vast network of resources and expertise. This partnership enables us to leverage CNBM's extensive supply chain and global presence, ensuring a seamless procurement process and timely delivery of your Steel Pipes.

With our years of market presence in Nauru, we have developed strong relationships with local suppliers, contractors, and authorities. This local knowledge and network allow us to navigate any challenges or regulatory requirements efficiently, saving you time and effort.

In summary, our comprehensive Steel Pipes solutions in Nauru encompass sales, pricing, and technical assistance. We offer a wide range of high-quality products, competitive prices, and expert support to meet your diverse needs. Contact us today to discuss your Steel Pipes requirements and let us assist you in achieving your project goals.

When it comes to pricing, we understand the importance of competitive rates without compromising on quality. Our strong partnerships with manufacturers allow us to negotiate favorable prices, ensuring that you get the best value for your investment. We also offer flexible payment options to accommodate your budget.

Technical assistance is another crucial aspect of our services. Our experienced engineers and technicians are available to provide guidance and support throughout your project, from the selection of the appropriate Steel Pipes to installation and maintenance. We stay updated with the latest industry standards and regulations to ensure that our solutions comply with all requirements.

Being affiliated with CNBM, a Fortune Global 500 company, gives us access to a vast network of resources and expertise. This partnership enables us to leverage CNBM's extensive supply chain and global presence, ensuring a seamless procurement process and timely delivery of your Steel Pipes.

With our years of market presence in Nauru, we have developed strong relationships with local suppliers, contractors, and authorities. This local knowledge and network allow us to navigate any challenges or regulatory requirements efficiently, saving you time and effort.

In summary, our comprehensive Steel Pipes solutions in Nauru encompass sales, pricing, and technical assistance. We offer a wide range of high-quality products, competitive prices, and expert support to meet your diverse needs. Contact us today to discuss your Steel Pipes requirements and let us assist you in achieving your project goals.