All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are aluminum coils used in the aerospace industry for structural components?

Aluminum coils are commonly used in the aerospace industry for manufacturing structural components due to their lightweight, high strength, and excellent corrosion resistance properties. These coils are often processed to form various parts such as wings, fuselage, and structural supports, providing structural integrity while minimizing the overall weight of the aircraft. Additionally, aluminum's malleability allows for intricate shaping and forming, making it a versatile material for constructing critical components in the aerospace industry.

What are the advantages of aluminum coils in the solar energy sector?

There are several advantages of using aluminum coils in the solar energy sector. Firstly, aluminum coils are lightweight which makes them easy to transport and install, reducing overall costs. Secondly, aluminum has excellent thermal conductivity, allowing for efficient heat transfer and better performance of solar panels. Additionally, aluminum is highly resistant to corrosion, ensuring durability and longevity of the solar panels. Lastly, aluminum is a highly recyclable material, making it environmentally friendly and sustainable for the solar energy industry.

How are aluminum coils transported to customers?

Aluminum coils are typically transported to customers using various methods including trucking, rail transportation, or shipping. The choice of transportation method depends on the distance to be covered, the quantity of coils, and the customer's location.

How do you ensure the flatness of aluminum coils?

To ensure the flatness of aluminum coils, various techniques are employed during the manufacturing process. These include tension leveling, roller leveling, and corrective leveling. Tension leveling involves stretching the coils to remove any waviness or unevenness, while roller leveling uses a series of rollers to flatten the surface. Corrective leveling is used to address any remaining irregularities by adjusting the tension or pressure applied to specific areas. Additionally, precise controls and monitoring systems are implemented to maintain consistent flatness throughout the production.

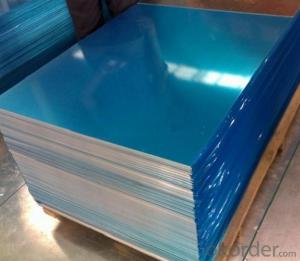

Wholesale Aluminum Coils from supplier in Honduras

Whether you are in need of Aluminum Coils for construction, manufacturing, or any other industry in Honduras, our company is here to meet your needs. We understand the importance of high-quality products and timely delivery, which is why we work closely with reputable manufacturers to ensure that our Aluminum Coils meet the highest standards.

Our team of experts is dedicated to providing excellent customer service and technical support. We can assist you with product selection, provide detailed quotes, and offer guidance on the best Aluminum Coils for your specific requirements. Our goal is to make the procurement process as smooth as possible for our customers in Honduras.

As a subsidiary platform of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This allows us to offer competitive prices and a wide range of Aluminum Coils options to choose from.

With our extensive experience in the Honduras market, we understand the unique challenges and requirements of different industries. Whether you are in the construction, automotive, or packaging sector, we can provide you with the expertise and solutions you need.

Contact us today to learn more about our Aluminum Coils products and how we can assist you in Honduras. We are committed to helping you find the right solutions for your projects and ensuring your satisfaction.

Our team of experts is dedicated to providing excellent customer service and technical support. We can assist you with product selection, provide detailed quotes, and offer guidance on the best Aluminum Coils for your specific requirements. Our goal is to make the procurement process as smooth as possible for our customers in Honduras.

As a subsidiary platform of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This allows us to offer competitive prices and a wide range of Aluminum Coils options to choose from.

With our extensive experience in the Honduras market, we understand the unique challenges and requirements of different industries. Whether you are in the construction, automotive, or packaging sector, we can provide you with the expertise and solutions you need.

Contact us today to learn more about our Aluminum Coils products and how we can assist you in Honduras. We are committed to helping you find the right solutions for your projects and ensuring your satisfaction.