Aluminum profile extrusion for led light strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

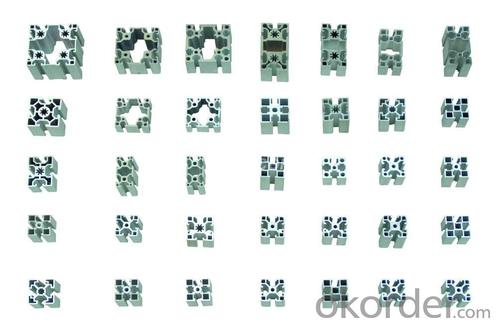

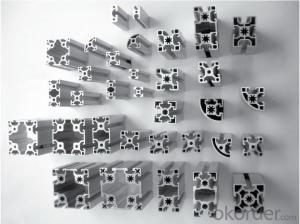

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: This question asks if there are any health hazards linked to handling aluminum profiles.

- <p>Generally, working with aluminum profiles does not pose significant health risks. Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries. However, inhalation of aluminum dust or fumes over long periods may cause respiratory issues. Workers should use appropriate personal protective equipment (PPE) such as masks and gloves to minimize exposure. Additionally, aluminum can cause skin irritation in some individuals, so skin contact should be avoided. It's important to follow safety guidelines and maintain good hygiene practices when working with aluminum profiles.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles within the construction industry.

- <p>Aluminum profiles offer several advantages in construction, including high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures and facilitates easier installation. Their resistance to corrosion means they require less maintenance and have a longer lifespan compared to steel. Additionally, aluminum profiles can be easily cut, bent, and joined, making them versatile for various applications. However, they have some disadvantages, such as lower thermal conductivity, which can be a concern in temperature-sensitive environments. They are also more expensive than some traditional materials like steel. Lastly, aluminum profiles can dent or deform under heavy loads, which may limit their use in certain structural applications.</p>

- Q: This question asks about the various types of aluminum profiles that are specifically used for flooring applications.

- <p>Aluminum profiles for flooring are designed to provide structural support and stability to the flooring system. Common types include: 1. T-profiles, which are used as support beams and can be easily connected to create a grid structure. 2. U-profiles, often used as edge trims or for creating a border around the flooring area. 3. H-profiles, which are suitable for heavy-duty applications and provide high load-bearing capabilities. 4. L-profiles, used for creating corners or edges in flooring systems. 5. C-profiles, which are used for covering or hiding the edges of the floor. Each type offers different benefits and is chosen based on the specific requirements of the flooring project, such as load capacity, aesthetic considerations, and ease of installation.</p>

- Q: Are aluminum profiles suitable for lighting fixtures?

- Yes, aluminum profiles are highly suitable for lighting fixtures. Aluminum is a versatile and lightweight material that offers several advantages for lighting applications. Firstly, aluminum profiles have excellent thermal conductivity, which means they effectively dissipate heat generated by the lighting fixtures. This is crucial as excessive heat can reduce the lifespan of the lighting components and affect their performance. Aluminum profiles help to maintain a cooler operating temperature, thereby enhancing the longevity and efficiency of the lighting fixtures. Secondly, aluminum profiles are corrosion-resistant, making them suitable for indoor and outdoor lighting fixtures. This resistance to corrosion ensures that the fixtures can withstand harsh environmental conditions, such as high humidity or exposure to moisture, without deteriorating or losing their functionality. Furthermore, aluminum profiles are easily customizable and can be designed to accommodate various lighting requirements. They can be extruded into different shapes and sizes, allowing for flexibility in the design of lighting fixtures. This versatility enables manufacturers to create sleek and modern lighting solutions that can be seamlessly integrated into different spaces and architectural designs. In addition, aluminum profiles offer aesthetic appeal as they can be powder-coated or anodized in various colors, providing a wide range of options to match different interior or exterior design themes. Lastly, aluminum is a sustainable material that is fully recyclable. Opting for aluminum profiles in lighting fixtures contributes to reducing environmental impact and supports the principles of sustainability. Overall, due to their thermal conductivity, corrosion resistance, versatility, aesthetic appeal, and sustainability, aluminum profiles are highly suitable for lighting fixtures and are widely used in the lighting industry.

- Q: How do aluminum profiles contribute to LEED certification?

- Aluminum profiles can contribute to LEED (Leadership in Energy and Environmental Design) certification in several ways. Firstly, aluminum is a highly sustainable material. It is one of the most abundant elements on Earth and can be easily recycled without losing its quality. Using aluminum profiles in construction projects reduces the demand for new raw materials, conserves energy, and minimizes greenhouse gas emissions. This aligns with LEED's focus on reducing the environmental impact of buildings. Additionally, aluminum profiles are lightweight yet durable, allowing for efficient transportation and installation. This can contribute to LEED points in the category of Sustainable Sites, which encourages the use of materials and techniques that minimize impacts on ecosystems and reduce pollution during construction. Furthermore, aluminum profiles can be used to improve energy efficiency in buildings. By incorporating thermal breaks and insulation, aluminum profiles can help prevent heat transfer and reduce energy consumption for heating or cooling. This can contribute to LEED points in the Energy and Atmosphere category, which promotes the use of energy-efficient systems and materials. Moreover, aluminum profiles are resistant to corrosion and require minimal maintenance over their lifespan. This durability can contribute to LEED points in the Materials and Resources category, which encourages the use of long-lasting, low-maintenance materials that minimize waste and the need for replacement. In conclusion, aluminum profiles contribute to LEED certification by promoting sustainability, reducing environmental impacts, improving energy efficiency, and enhancing the durability of buildings. By considering the use of aluminum profiles in construction projects, designers and builders can achieve LEED credits and contribute to a more sustainable future.

- Q: This question asks for an overview of the typical materials used in the production of aluminum profiles.

- <p>Aluminum profiles are commonly made from various aluminum alloys, each with specific properties suited for different applications. The most common materials include 6063 aluminum alloy, known for its good mechanical properties and corrosion resistance, making it ideal for construction and industrial applications. 6061 aluminum alloy is also widely used due to its high strength-to-weight ratio and is often found in aerospace and automotive industries. Other alloys such as 6082 and 7075 are used for their superior strength and are common in heavy-duty applications. Each alloy is chosen based on the required strength, weight, and resistance to environmental factors for the intended use of the aluminum profile.</p>

- Q: Is it possible to utilize aluminum profiles as a material for exterior wall cladding?

- <p>Yes, aluminum profiles are commonly used for exterior cladding due to their durability, low maintenance, and resistance to corrosion. They are lightweight, easy to install, and can be designed in various shapes and sizes to suit architectural requirements. Additionally, aluminum profiles offer excellent weather resistance and can be painted or anodized to provide a protective finish and aesthetic appeal.</p>

- Q: Is it possible to tailor aluminum profiles to fulfill particular design and aesthetic needs?

- <p>Yes, aluminum profiles can be customized to meet specific aesthetic requirements. Manufacturers offer a variety of finishes, colors, and surface treatments to enhance the visual appeal of aluminum profiles. Additionally, the profiles can be cut, bent, and shaped to fit unique design specifications. This customization allows for a high degree of flexibility in creating structures and designs that are both functional and visually appealing, making aluminum profiles suitable for a wide range of applications from architectural to industrial design.</p>

- Q: Can aluminum profiles be used in the construction of green buildings?

- Absolutely, aluminum profiles are certainly suitable for use in the construction of environmentally friendly buildings. Aluminum is a remarkably sustainable material that brings about a plethora of benefits for green building initiatives. To begin with, aluminum is a lightweight substance that facilitates easier transportation and handling during construction. Consequently, this reduces energy consumption and carbon emissions involved in transportation. Moreover, aluminum is highly recyclable. It can be melted down and reused without any compromise in quality, making it an ideal selection for sustainable construction. This recyclability also diminishes the need for extracting and processing new aluminum, consequently reducing the environmental impact. Additionally, aluminum boasts exceptional durability and resistance to corrosion, which means it can endure for an extended period without frequent maintenance or replacement. This, in turn, reduces the requirement for new materials and minimizes waste throughout the building's lifespan. Furthermore, aluminum profiles can be designed to enhance energy efficiency in green buildings. They can be utilized for windows, doors, and curtain walls, providing exceptional thermal insulation and minimizing heat loss or gain. This, in turn, diminishes the energy consumption necessary for heating or cooling the building, resulting in lower carbon emissions. Furthermore, aluminum is a non-toxic material that does not release harmful chemicals into the environment, ensuring a healthier indoor environment for occupants. In conclusion, aluminum profiles offer a multitude of advantages for green building construction. Their lightweight nature, recyclability, durability, energy efficiency, and non-toxicity make them an optimal sustainable choice for green building projects.

- Q: Are aluminum profiles suitable for medical equipment and devices?

- Certainly, medical equipment and devices can indeed benefit from the use of aluminum profiles. Aluminum, being a versatile material, offers numerous advantages in the field of medical applications. Firstly, its lightweight nature renders it highly suitable for portable medical devices, thereby facilitating easy transportation, particularly in urgent situations. Moreover, the corrosion-resistant properties of aluminum are of utmost importance in maintaining the sterility and cleanliness of medical equipment. Furthermore, the material's durability allows it to withstand harsh environments and endure regular cleaning and sterilization procedures. Additionally, the adaptability of aluminum profiles enables effortless customization and fabrication into various shapes and sizes, thereby catering to diverse medical device designs. In conclusion, the exceptional characteristics of aluminum make it a dependable and appropriate choice for medical equipment and devices.

Send your message to us

Aluminum profile extrusion for led light strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords