Aluminum Profiles for Exhibition Stands:Custom Length LED Strip Light Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Profile For Led Strip Light And Length Customed Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile For Led Strip Light And Length Customed:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

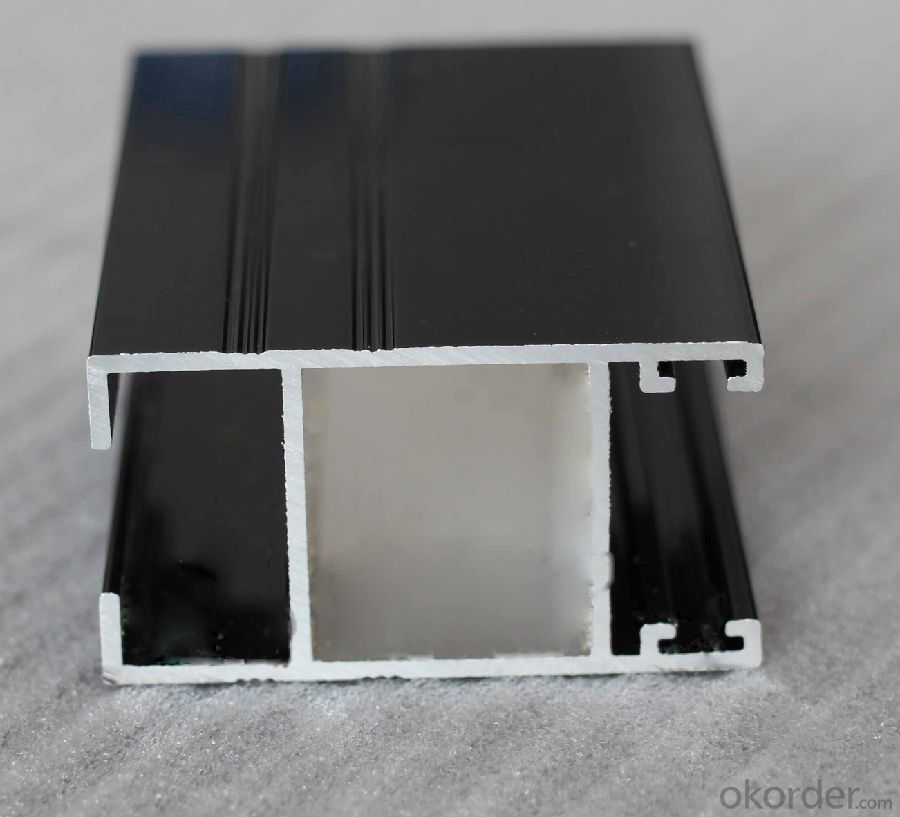

3.Aluminum Profile For Led Strip Light And Length Customed Images:

4.Aluminum Profile For Led Strip Light And Length Customed Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do aluminum profiles perform in terms of energy efficiency?

- Aluminum profiles are known for their excellent energy efficiency properties. They are widely used in various industries and applications, including construction, transportation, and manufacturing, due to their ability to contribute to energy savings and sustainability. One of the main reasons for their energy efficiency is the lightweight nature of aluminum. Compared to other materials like steel, aluminum profiles are significantly lighter, which means less energy is required for transportation and installation. This reduces the overall carbon footprint associated with the manufacturing and use of aluminum profiles. Additionally, aluminum has a high thermal conductivity, which allows for efficient heat transfer. This property is particularly beneficial in windows and doors applications. Aluminum profiles can effectively regulate the transfer of heat between the interior and exterior of a building, thereby reducing the need for excessive heating or cooling. This results in energy savings and reduced energy consumption. Furthermore, aluminum profiles can be easily integrated with additional energy-efficient components, such as thermal breaks and insulating materials. These additions further enhance the energy performance of aluminum profiles by minimizing thermal bridging and improving insulation, thus reducing energy loss. Moreover, aluminum is a highly durable and long-lasting material, which means that structures and products made with aluminum profiles require less maintenance and replacement over time. This durability contributes to overall energy efficiency by reducing the energy and resources needed for repairs and replacements. In conclusion, aluminum profiles are highly regarded for their energy efficiency characteristics. They are lightweight, have excellent thermal conductivity, can be integrated with energy-efficient components, and offer long-term durability. These qualities make aluminum profiles a sustainable choice that can contribute to energy savings and reduced environmental impact in various applications.

- Q: Are there any limitations on the length of aluminum profiles?

- Yes, there are limitations on the length of aluminum profiles. The length of aluminum profiles is typically limited by the practical constraints of transportation and handling. Longer profiles may be more difficult to transport and may require special equipment or transportation methods. Additionally, longer profiles may be more prone to bending or warping, which can affect their structural integrity. Therefore, manufacturers often have specific maximum lengths for aluminum profiles based on these considerations.

- Q: How are aluminum profiles cut and shaped?

- Depending on the desired result, there are various methods available for cutting and shaping aluminum profiles. One popular approach involves the use of saws. Whether it's a hand saw or a power saw like a miter saw or circular saw, specially designed blades capable of cutting through aluminum are utilized. Alternatively, CNC (Computer Numerical Control) machines provide a highly precise option. By programming these machines, aluminum profiles can be cut and shaped with great accuracy. This technique is particularly suitable for intricate and complex designs. Shaping aluminum profiles can be achieved through different techniques as well. For instance, bending is a common method. Specialized bending machines apply force gradually to achieve the desired angle without causing any damage or deformation to the aluminum. Another shaping technique is extrusion. This involves forcing the aluminum through a die to create a specific shape. Extrusion is commonly employed in the manufacturing of aluminum profiles with consistent cross-sectional shapes like tubes or beams. Overall, achieving the desired results in cutting and shaping aluminum profiles necessitates the use of specialized tools and machinery. The specific method chosen depends on the complexity of the design and the desired outcome.

- Q: Are aluminum profiles suitable for indoor applications with high humidity?

- Aluminum profiles are indeed a fitting option for indoor applications in environments with high humidity. Due to its non-corrosive nature and impressive moisture resistance, aluminum is an excellent choice. It remains unaffected by rust or deterioration when exposed to moisture, ensuring its longevity and durability. Moreover, aluminum profiles can be enhanced with protective finishes like anodizing or powder coating, which further fortifies their resistance against humidity, preventing any potential harm. Thus, aluminum profiles emerge as a dependable and appropriate choice for indoor applications in high humidity environments.

- Q: What are the thermal properties of aluminum profiles?

- Aluminum profiles have excellent thermal properties. They have high thermal conductivity, allowing heat to be transferred quickly and efficiently. They also have a low coefficient of thermal expansion, meaning they can withstand temperature changes without significant distortion or damage. Additionally, aluminum profiles have good heat dissipation capabilities, making them suitable for applications requiring heat management, such as in electronic devices or heat sinks.

- Q: Are aluminum profiles suitable for furniture applications?

- Yes, aluminum profiles are suitable for furniture applications. Aluminum is a lightweight and durable material that can be easily shaped and manipulated to create various furniture designs. It provides stability and strength to furniture pieces while also offering a sleek and modern aesthetic. Additionally, aluminum is resistant to rust and corrosion, making it suitable for both indoor and outdoor furniture applications.

- Q: Can aluminum profiles be used in the construction of solar panels?

- Yes, aluminum profiles can be used in the construction of solar panels. Aluminum is a lightweight and durable material that is commonly used in various industries, including construction and solar energy. It offers several advantages when used in the manufacturing of solar panels. Firstly, aluminum profiles provide structural support and stability to the solar panel system. They can be easily shaped and formed into various designs, allowing for flexibility in panel assembly. Additionally, aluminum has excellent corrosion resistance, ensuring the longevity and durability of the panels in different weather conditions. Furthermore, aluminum profiles are highly conductive, which is crucial for the efficient functioning of solar panels. They help to dissipate heat generated by the solar cells, preventing overheating and enhancing the overall performance and lifespan of the panels. Moreover, aluminum is a sustainable and eco-friendly material. It can be easily recycled and reused, reducing the environmental impact of solar panel production. This aligns with the principles of renewable energy and sustainability, making aluminum profiles a preferred choice in the construction of solar panels. In conclusion, aluminum profiles can be effectively utilized in the construction of solar panels due to their structural strength, corrosion resistance, thermal conductivity, and sustainability. Their usage ensures the reliability, efficiency, and eco-friendliness of solar panel systems.

- Q: This question asks about the methods to ensure that aluminum profiles used in construction meet safety standards.

- <p>To ensure that aluminum profiles used in building construction meet safety standards, you should follow these steps: 1) Source from reputable suppliers who adhere to industry standards. 2) Check for certifications such as ISO 9001 for quality management. 3) Verify the aluminum's grade and alloy type to ensure it's suitable for construction use. 4) Conduct regular inspections and tests, including tensile strength and load-bearing capacity tests. 5) Adhere to local building codes and regulations. 6) Use profiles with appropriate thickness and dimensions for the intended application. 7) Consult with engineers or architects to ensure proper design and installation. 8) Keep records of all tests and inspections for future reference and compliance checks.</p>

- Q: Are aluminum profiles suitable for industrial workstations?

- Yes, aluminum profiles are suitable for industrial workstations. Aluminum is a lightweight and durable material that provides excellent strength and stability, making it ideal for use in industrial settings. It has high corrosion resistance, which helps to prolong the lifespan of the workstations. Additionally, aluminum profiles can be easily customized and assembled, allowing for flexibility and adaptability in designing the workstations to meet specific industrial needs. The material is also environmentally friendly, as it is 100% recyclable, which aligns with the growing emphasis on sustainability in the industrial sector. Overall, aluminum profiles offer numerous advantages for industrial workstations, making them a suitable choice for various applications in industrial settings.

- Q: Can aluminum profiles be an alternative to wood in construction?

- Yes, aluminum profiles can be a viable alternative to wood in construction. Aluminum profiles offer several advantages over wood, making them a popular choice in many construction projects. Firstly, aluminum profiles are lightweight yet strong, allowing for easy handling and installation. This characteristic makes them suitable for various applications, including frames for doors, windows, curtain walls, and partitions. Additionally, aluminum profiles have excellent durability and resistance to weathering, corrosion, and pests, making them a long-lasting and low-maintenance option. Furthermore, aluminum profiles have inherent fire-resistant properties, which can enhance safety in construction. Unlike wood, aluminum does not burn, and it has a high melting point, making it less likely to contribute to the spread of fires. In terms of sustainability, aluminum profiles can offer environmental benefits. Aluminum is a highly recyclable material, meaning that it can be reused and repurposed multiple times without losing its properties. This recyclability reduces the environmental impact associated with construction projects and supports the circular economy. Another advantage of using aluminum profiles is their design versatility. Aluminum can be easily shaped and extruded into various profiles and sizes, allowing for customization and flexibility in architectural designs. This adaptability makes aluminum profiles suitable for both functional and aesthetic purposes in construction. However, it is important to note that aluminum profiles may have higher upfront costs compared to wood. Additionally, the thermal conductivity of aluminum is higher than that of wood, which means that aluminum profiles may require additional insulation to provide optimal thermal performance. In conclusion, aluminum profiles can be a viable alternative to wood in construction due to their lightweight, durability, fire resistance, sustainability, and design versatility. While there may be some considerations regarding cost and thermal conductivity, the benefits of aluminum profiles make them an attractive option for various construction applications.

Send your message to us

Aluminum Profiles for Exhibition Stands:Custom Length LED Strip Light Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords