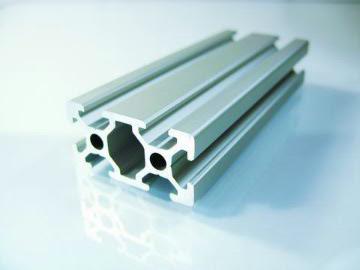

Industrial Aluminum Profile for LED Tape Light Strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industial Aluminum Profile

Alloy: 6063, Temper: T5, T6.

surface:mill finished,anodized3.

widely used for building,furniture,transportation

Industial Aluminum Profile

Alloy: 6063,

Temper: T5, T6.

building,furniture,transportation,machine

Anodized silver, anodized champagne, anodized bronze, anodized black, powder coated, electrophoresis, polished, Thermal break, wooden grain.

Length: 5.8---6 meters, depend on customers' requested.

Packing: kraft paper, carton, or on customers' requested.

Exported to different countries worldwide.

- Q: This question asks for methods to reduce waste associated with the production and utilization of aluminum profiles in the construction industry.

- <p>To minimize waste during the production and use of aluminum profiles in construction, one can adopt several strategies: 1. Optimize production processes to reduce material waste by using precision cutting and advanced manufacturing techniques. 2. Implement recycling programs to repurpose scrap aluminum, reducing the need for raw material extraction. 3. Design buildings with modular aluminum components that can be easily disassembled and reused in future projects. 4. Educate construction workers on proper handling and storage to prevent damage and waste. 5. Use computer-aided design (CAD) to accurately plan material requirements, minimizing offcuts. 6. Choose sustainable aluminum sources and suppliers that prioritize waste reduction. 7. Regularly audit and update production methods to incorporate new waste reduction technologies and practices.</p>

- Q: This question asks for a list of various types of aluminum profiles that are commonly used in the construction industry.

- <p>Aluminum profiles used in construction come in various types, each with specific applications. Common types include: 1. Extruded Profiles: These are the most common, formed by forcing aluminum through a die to create different shapes and sizes. 2. Structural Profiles: Used for structural integrity, such as beams and columns. 3. Decorative Profiles: For aesthetic purposes, like trims and moldings. 4. Industrial Profiles: Designed for specific industrial applications, like conveyor systems. 5. Window and Door Profiles: Specifically designed for window and door frames. 6. Heat Sink Profiles: Used for dissipating heat in electronic devices. 7. Railing Profiles: For constructing railings and balustrades. 8. Solar Profiles: Used in solar panel mounting systems. Each type has unique properties and is chosen based on the specific requirements of the construction project.</p>

- Q: What tests do the aluminum profiles used in the curtain wall project do?

- Aluminum alloy material3.2.1 glass curtain wall by chemical composition corresponding to Aluminum Alloy material grades should be consistent with current national standard "the relevant provisions of the chemical composition" deformation of aluminum and Aluminum Alloy GB / T 3190, the quality of Aluminum Alloy section shall comply with the provisions of the current national standard "Aluminum Alloy architecture" GB / T 5237, section size deviation should be allowed to high grade or ultra high grade.3.2.2 Aluminum Alloy profiles by anodic oxidation, electrophoretic coating, powder coating, fluorocarbon paint spraying surface treatment, quality should be consistent with current national standard "Aluminum Alloy architecture" GB / T 5237 requirements, the thickness of surface layer should meet the requirements in table 3.2.2.3.2.3 insulated aluminum profiles produced by the strip process shall be made of PA66GF25 (polyamide 66+25 glass fiber) material and shall not be made of PVC material. A heat insulated aluminum profile produced by pouring process shall be made of PUR (polyurethane) material. The shear strength of the joint must meet the design requirements.3.2.4 and glass curtain wall matching aluminum alloy doors and windows should comply with the current national standard "aluminum alloy door", GB / T 8478 and aluminum alloy window "GB/T 8479" provisions.

- Q: Are aluminum profiles suitable for use in food processing environments?

- Yes, aluminum profiles are suitable for use in food processing environments. Aluminum is a widely used material in the food industry due to its excellent properties. It is lightweight, durable, and corrosion-resistant, making it ideal for applications in food processing where hygiene and cleanliness are crucial. Aluminum profiles can be easily cleaned and sanitized, which is essential in preventing contamination and ensuring food safety. They have a smooth and non-porous surface, which inhibits the growth of bacteria and makes them easy to maintain. Furthermore, aluminum has excellent thermal conductivity, allowing for efficient heat transfer and temperature control during food processing. This property is particularly important in applications such as food packaging, cooking, and chilling. In addition to its physical properties, aluminum is also non-toxic and does not react with food or beverages. It is an inert material, meaning it does not release any harmful substances that could contaminate the food being processed. Overall, aluminum profiles are a reliable and suitable choice for use in food processing environments. They meet the stringent requirements of the industry in terms of hygiene, durability, and safety, making them a popular choice for various applications in the food processing and packaging sectors.

- Q: the middle of the following is a groove structure, as if you can not bolt hole, then how to install the rail on it? What's the use of flat sealing strips and slip bars embedded inside? Is it necessary to mount the guide rail on the aluminum profile, you can choose more than 6060 of the profiles, the middle is flat structure, and then drill holes in the bolt connection rail Thanks

- Use the T nuts (in the T groove) to fit the rail! Flat sealing strips and slip bars are embedded inside for dust proof, waterproof, oil proof and so on!!!Satisfaction, please adopt

- Q: What specific considerations or criteria must be met when using aluminum profiles in the construction of high-rise buildings?

- <p>Yes, there are special requirements for using aluminum profiles in high-rise buildings. These include high strength and load-bearing capacity to withstand the weight and wind forces. Durability is crucial to resist corrosion and weathering over time. Fire resistance is also important for safety. Additionally, aluminum profiles must comply with building codes and regulations specific to high-rise structures. They should also have good thermal insulation properties to maintain energy efficiency and comfort. Lastly, aesthetic considerations are important as the profiles contribute to the building's exterior appearance.</p>

- Q: How do aluminum profiles perform in blast-resistant structures?

- Aluminum profiles perform well in blast-resistant structures due to their high strength-to-weight ratio and excellent energy absorption capabilities. They can effectively dissipate and redirect the force of an explosion, minimizing damage and providing enhanced protection. Additionally, aluminum profiles offer corrosion resistance, durability, and ease of fabrication, making them a suitable choice for blast-resistant construction.

- Q: Can aluminum profiles be used in the construction of greenhouses?

- Yes, aluminum profiles can be used in the construction of greenhouses. Aluminum is a popular choice for greenhouse framing due to its durability, lightweight nature, and resistance to corrosion. It offers structural strength while allowing for maximum light transmission, which is essential for plant growth. Additionally, aluminum profiles are easy to assemble and maintain, making them an ideal material for constructing greenhouses.

- Q: This question asks for methods to protect aluminum profiles from corrosion and damage during the processes of transportation and storage.

- <p>To prevent corrosion and damage to aluminum profiles during transportation and storage, follow these guidelines: 1. Keep aluminum profiles dry and clean. Moisture and dirt can accelerate corrosion. 2. Use protective packaging, such as plastic wrap or padded covers, to shield profiles from physical damage and moisture. 3. Store profiles in a cool, dry place away from direct sunlight and corrosive substances. 4. Stack profiles with appropriate padding between layers to prevent scratching. 5. Avoid overloading during transportation and ensure secure fastening to prevent movement and potential damage. 6. Regularly inspect stored profiles for signs of corrosion or damage and address any issues promptly.</p>

- Q: What are the weatherproofing properties of aluminum profiles?

- Due to their inherent characteristics and manufacturing processes, aluminum profiles possess excellent weatherproofing properties. This is due to aluminum being a naturally corrosion-resistant material, allowing it to endure exposure to different weather conditions without deteriorating or rusting. It forms a protective layer of oxide on its surface, serving as an additional barrier against moisture and preventing further corrosion. Moreover, various weatherproofing techniques can further enhance aluminum profiles. Anodizing is a common method where the aluminum surface undergoes an electrolytic process to create a thicker and more durable oxide layer. This not only improves weather resistance but also enhances resistance to scratching and wear. Furthermore, aluminum profiles can be coated with protective finishes like powder coating or liquid paint. These coatings not only add aesthetic appeal but also provide an extra layer of protection against UV radiation, moisture, and other weather elements. Powder coating, in particular, offers exceptional durability and resistance to fading, chipping, and cracking. Additionally, aluminum profiles can be designed to incorporate weatherproof features such as gaskets, seals, and thermal breaks. These elements establish a tight seal between the profile and other building components, preventing water infiltration, air leakage, and thermal transfer. They contribute to maintaining a comfortable indoor environment, reducing energy consumption, and enhancing the overall weatherproofing performance of the aluminum profiles. In summary, the weatherproofing properties of aluminum profiles make them a popular choice for a wide range of applications, including windows, doors, curtain walls, roofing systems, and outdoor furniture. Their ability to withstand harsh weather conditions, resistance to corrosion, and availability of protective coatings make them a dependable and long-lasting option for both residential and commercial projects.

Send your message to us

Industrial Aluminum Profile for LED Tape Light Strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords