Bosch Aluminum Extrusion Profiles for LED Light Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

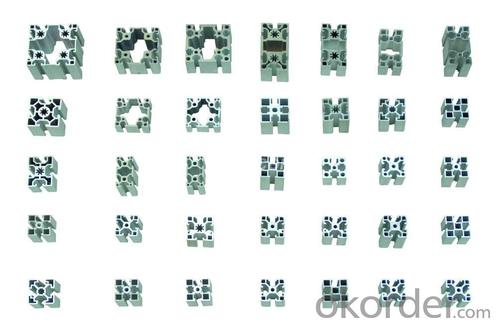

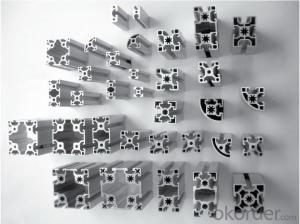

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Can aluminum profiles be used in the construction of amusement park rides?

- Yes, aluminum profiles can be used in the construction of amusement park rides. Aluminum is a lightweight and durable material that can withstand various loads and stresses. It offers excellent corrosion resistance and can be easily shaped into different profiles to suit the specific design requirements of amusement park rides. Additionally, aluminum's high strength-to-weight ratio makes it an ideal choice for supporting structures and frames, ensuring the safety and stability of the rides.

- Q: What unique considerations or criteria must be met when installing aluminum profiles to ensure they are correctly installed?

- <p>Yes, there are special requirements for installing aluminum profiles correctly. These include ensuring the profiles are of the correct size and specifications for the intended application, proper alignment to maintain structural integrity, and secure fastening to prevent movement or damage. Additionally, it's crucial to follow the manufacturer's guidelines for installation, which may include specific torque settings for screws or bolts, and to consider environmental factors such as temperature and humidity that could affect the profile's performance over time. Proper installation also involves checking for any damage or defects in the profiles before installation and ensuring that all components are compatible with each other.</p>

- Q: Can aluminum profiles be utilized in creating distinctive architectural structures?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, lightweight, and corrosion resistance. Architects can utilize aluminum's flexibility to design complex structures, such as intricate facades, modern window systems, and innovative support frameworks. Aluminum's adaptability allows for both functional and aesthetically pleasing designs, making it a popular choice in contemporary architecture.</p>

- Q: Are aluminum profiles painted by powder or by fluorocarbon spray? How can they be distinguished from appearance?

- The biggest weakness of powder spraying is that it is afraid of the ultraviolet radiation of the sun. The long-term radiation will cause the natural fading. The face of the aluminum plate and the non bright face are obviously different in color after a few years, and the color difference is obvious for 2-5 years. Now appearing on the market name of color for aluminum, aluminum doors and windows, is to use ordinary aluminum powder coating and. Aluminum doors and windows to increase color varieties, but also to enhance corrosion resistance. Another kind of electrostatic spraying liquid spraying, also called fluorocarbon spraying called curium oil, Hongkong. Belonging to high-grade spraying, higher prices, has long been applied in foreign countries. In the past two years, it has been widely used in aluminum curtain wall. Because of its excellent characteristics, more and more attention has been paid to the construction industry and users. Fluorocarbon coating has excellent anti fade, anti frost, anti air pollution (acid rain) corrosion, anti UV ability, strong crack resistance and can withstand harsh weather conditions. Is less than general paint

- Q: Are aluminum profiles suitable for use as exterior wall materials?

- <p>Yes, aluminum profiles can be used for exterior walls. They are known for their durability, resistance to weathering, and low maintenance requirements. Aluminum is lightweight, strong, and can be easily shaped into various designs. It also has excellent resistance to corrosion, making it ideal for outdoor applications. Additionally, aluminum profiles can be powder coated or anodized for enhanced protection and aesthetic appeal, allowing them to blend well with different architectural styles.</p>

- Q: Is it feasible to recycle aluminum profiles economically and in significant quantities?

- <p>Yes, aluminum profiles can be recycled at a reasonable cost and volume. Recycling aluminum is more cost-effective than mining and refining new aluminum from bauxite. The process requires less energy, which reduces costs. Additionally, aluminum has a high recycling rate, with about 75% of all aluminum ever produced still in use today. This indicates that aluminum recycling is both economically viable and can be done in significant volumes, contributing to sustainability and waste reduction.</p>

- Q: Can aluminum profiles be used for security doors and windows?

- Yes, aluminum profiles can be used for security doors and windows. Aluminum is a lightweight and durable material that can withstand force and resist corrosion. It can be customized to include additional security features such as multi-point locking systems, reinforced frames, and impact-resistant glass. Additionally, aluminum profiles offer a sleek and modern appearance, making them a popular choice for security doors and windows in residential and commercial properties.

- Q: This question asks for a list of different types of fasteners that are typically used in conjunction with aluminum extrusions.

- <p>Common types of fasteners used with aluminum extrusions include: 1. T-nuts and T-bolts, which provide a secure way to mount components to the extrusion. 2. Clamps and brackets, which can be used to hold items in place without drilling. 3. Corner brackets, which are used to connect two extrusions at right angles. 4. End caps, which protect the ends of the extrusion and can also serve as a mounting point. 5. Dowel pins, which are used to align and secure extrusions together. 6. Spacers, which maintain a consistent distance between extrusions. 7. Adhesives, which can be used for bonding parts to the extrusion. 8. Rivets, which provide a permanent connection between extrusions and other materials. These fasteners are chosen based on the specific application, load requirements, and design considerations.</p>

- Q: Features of aluminum profiles

- Thermal conductivityThe thermal conductivity of aluminum alloy is about 50-60% of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, and the cylinder head and radiator of automobiles.FerromagnetismAluminum is non ferromagnetic, which is an important feature of the electrical and electronic industries. Aluminum can not be spontaneous combustion, which is involved in loading and unloading or exposure to flammable and explosive materials is important.

- Q: What are the different types of surface coatings for aluminum profiles?

- There are several different types of surface coatings that can be applied to aluminum profiles, each with their own unique characteristics and benefits. 1. Anodizing: Anodizing is a popular coating method that involves creating a protective oxide layer on the surface of the aluminum. This layer not only enhances the appearance of the profile but also improves its resistance to corrosion, wear, and scratches. Anodized aluminum profiles can be further enhanced through color dyeing or other finishing techniques. 2. Powder coating: Powder coating is a dry finishing process that involves applying a powdered coating material to the aluminum profile. The powder is electrostatically charged and then applied to the profile, after which it is heated to form a durable and attractive coating. Powder coating offers excellent protection against scratches, UV rays, and chemical damage, making it a popular choice for outdoor applications. 3. Liquid paint coating: Liquid paint coatings can also be applied to aluminum profiles. This method involves spraying or dipping the profile into a liquid paint solution, which is then cured to form a tough and durable finish. Liquid paint coatings offer a wide range of color options and can be customized to achieve specific aesthetic requirements. 4. PVDF coating: Polyvinylidene fluoride (PVDF) is a high-performance coating material that provides exceptional resistance to weathering, fading, and corrosion. PVDF coatings are typically applied through a liquid paint process and can be used to achieve long-lasting and vibrant finishes on aluminum profiles, especially in architectural applications. 5. E-coating: Electrocoating, also known as electrophoretic deposition (EPD), involves immersing the aluminum profile in a bath of paint or coating solution and applying an electric current to deposit the paint uniformly onto the surface. E-coating provides excellent coverage and adhesion, making it suitable for complex-shaped profiles. It also offers good corrosion resistance and can be used as a primer before applying other coatings. Overall, the choice of surface coating for aluminum profiles depends on the specific requirements of the application, including desired appearance, durability, corrosion resistance, and environmental factors. Each type of coating has its own advantages and limitations, so it is important to carefully consider these factors before making a selection.

Send your message to us

Bosch Aluminum Extrusion Profiles for LED Light Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords