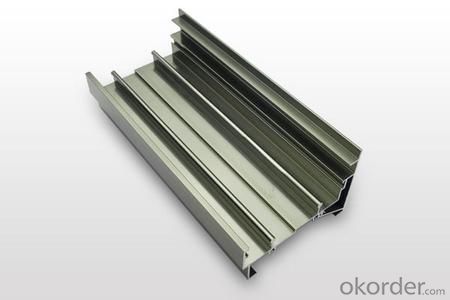

Aluminum Door Profiles for Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

- Q: What precautions should be taken while handling aluminum profiles to ensure safety?

- <p>When working with aluminum profiles, it's important to take several safety measures. Always wear appropriate personal protective equipment (PPE), including safety glasses to protect your eyes from flying debris, gloves to protect your hands, and a dust mask to prevent inhalation of dust particles. Ensure that the work area is well-ventilated to avoid inhaling aluminum dust. Use proper tools for cutting and shaping aluminum profiles to minimize the risk of injury. Keep the work area clean and free from clutter to prevent tripping hazards. Be cautious when handling sharp edges and ends of cut aluminum profiles. Lastly, be aware of the weight of the aluminum profiles to avoid back injuries when lifting.</p>

- Q: This question asks for a list of various types of aluminum profiles that are commonly used in the construction industry.

- <p>Aluminum profiles used in construction come in various types, each with specific applications. Common types include: 1. Extruded Profiles: These are the most common, formed by forcing aluminum through a die to create different shapes and sizes. 2. Structural Profiles: Used for structural integrity, such as beams and columns. 3. Decorative Profiles: For aesthetic purposes, like trims and moldings. 4. Industrial Profiles: Designed for specific industrial applications, like conveyor systems. 5. Window and Door Profiles: Specifically designed for window and door frames. 6. Heat Sink Profiles: Used for dissipating heat in electronic devices. 7. Railing Profiles: For constructing railings and balustrades. 8. Solar Profiles: Used in solar panel mounting systems. Each type has unique properties and is chosen based on the specific requirements of the construction project.</p>

- Q: Can someone give me a direction? Thank you

- Guangdong now has a lot of aluminum factory, and the price is very low

- Q: This question asks if aluminum profiles can be utilized in the construction or design of interior wall systems.

- <p>Yes, aluminum profiles are commonly used for interior wall systems. They offer numerous benefits such as durability, lightweight, and resistance to corrosion. These profiles can be used in various applications, including partition walls, decorative panels, and structural supports. Their versatility allows for a wide range of design possibilities, and they are easy to install and maintain, making them a popular choice in modern interior design and construction.</p>

- Q: Ask you, China aluminum plate production factory, supply distribution in the provinces in which the details, please.

- A large share of the domestic market, mainly in Shanghai, Guangdong, Chongqing and other provinces and cities, the other areas are relatively small.From the regional distribution, aluminum production in East China is the highest, followed by South Central China. The provinces and municipalities in Jiangsu, Zhejiang, Guangdong and Chongqing have the highest output.Fengcheng global resource recycling technology development Co., ltd..

- Q: This question asks for a variety of green building materials that incorporate recycled aluminum profiles, indicating an interest in sustainable construction practices.

- <p>Recycled aluminum profiles are used in various green building materials to promote sustainability. These include: 1) Window and door frames, known for their durability and energy efficiency. 2) Facade systems, which provide a lightweight and strong alternative to traditional materials. 3) Structural components, such as beams and columns, offering strength with less material. 4) Roofing materials, which can be lightweight and resistant to corrosion. 5) Modular building systems, which use prefabricated aluminum components for quick assembly. 6) Fencing and railings, offering a low-maintenance option. 7) Solar panel supports, combining recycled aluminum with renewable energy technology. These materials reduce waste, save energy, and lower carbon emissions in construction.</p>

- Q: Are aluminum profiles suitable for use in food processing environments?

- Yes, aluminum profiles are suitable for use in food processing environments. Aluminum is a widely used material in the food industry due to its excellent properties. It is lightweight, durable, and corrosion-resistant, making it ideal for applications in food processing where hygiene and cleanliness are crucial. Aluminum profiles can be easily cleaned and sanitized, which is essential in preventing contamination and ensuring food safety. They have a smooth and non-porous surface, which inhibits the growth of bacteria and makes them easy to maintain. Furthermore, aluminum has excellent thermal conductivity, allowing for efficient heat transfer and temperature control during food processing. This property is particularly important in applications such as food packaging, cooking, and chilling. In addition to its physical properties, aluminum is also non-toxic and does not react with food or beverages. It is an inert material, meaning it does not release any harmful substances that could contaminate the food being processed. Overall, aluminum profiles are a reliable and suitable choice for use in food processing environments. They meet the stringent requirements of the industry in terms of hygiene, durability, and safety, making them a popular choice for various applications in the food processing and packaging sectors.

- Q: Do aluminum profiles require any special maintenance?

- Aluminum profiles do not require any special maintenance. Aluminum is a durable and low-maintenance material that is resistant to corrosion, rust, and weathering. Unlike other materials such as wood or steel, aluminum profiles do not need to be regularly painted, stained, or treated to maintain their appearance or functionality. Additionally, aluminum is lightweight, making it easy to handle and install. However, it is important to keep the aluminum profiles clean by regularly removing dirt or debris with a mild detergent and water solution. This will help to preserve the aesthetic appeal and longevity of the profiles. Overall, aluminum profiles are a convenient and hassle-free option for various applications, as they do not require any special maintenance.

- Q: Are aluminum profiles suitable for exhibition displays?

- Yes, aluminum profiles are highly suitable for exhibition displays. They are lightweight, durable, and can be easily customized to fit various display requirements. Aluminum profiles also offer a sleek and modern aesthetic, making them ideal for creating visually appealing exhibition displays. Additionally, they are versatile and can be easily assembled and disassembled, allowing for easy transportation and setup at different exhibition venues.

- Q: How is the thickness of the base plate of the aluminum profile radiator calculated? Are there formulas for calculation?

- There should be empirical formula, the heat of the surface heat dissipation is related to thermal conductivity, thickness, temperature change, surface area. Then the best thickness is calculated by linear programming.

Send your message to us

Aluminum Door Profiles for Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords