Aluminum Extrusion Profiles from Japan for Honda Spareparts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Extrusion For Honda Spareparts Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Extrusion For Honda Spareparts:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

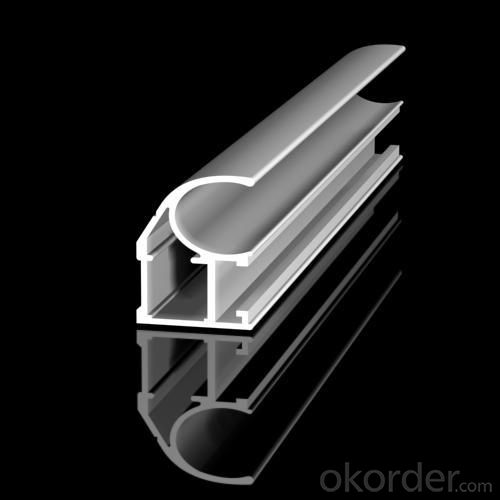

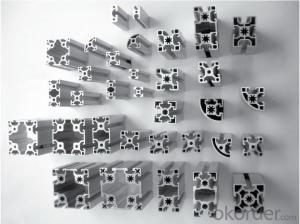

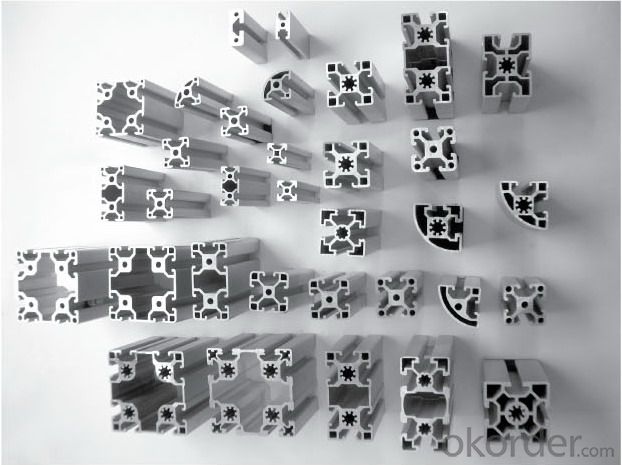

Images of the Aluminium Extrusion For Honda Spareparts:

Aluminium Coins for Deep Drawing to Tube Comestic Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: This question asks whether aluminum profiles are appropriate for construction in regions with a high risk of earthquakes.

- <p>Aluminum profiles are indeed suitable for use in earthquake-prone areas. They are lightweight, which reduces the overall weight of structures, making them less susceptible to damage from seismic forces. Additionally, aluminum profiles have high ductility and can absorb and distribute seismic energy effectively, enhancing the building's resilience to earthquakes. Their corrosion resistance and durability also contribute to the longevity of structures in such regions. However, it's crucial to ensure that these profiles are properly engineered and installed according to seismic-resistant building codes to maximize their effectiveness.</p>

- Q: What is the thickness of the aluminum alloy window frame?

- The national standard "Aluminum Alloy window" has been specified, aluminum wall thickness not less than 1.2 mm. In other words, the main wall thickness of ordinary aluminum alloy window structure should not be less than 1.2 mm, the main wall thickness of the door structure profiles should not be less than 2 mm.

- Q: Is the aluminum profile insulated and broken hot?

- Yes, the name is not the same, the professional name is "broken hot aluminum alloy", most people used to call "broken bridge aluminum"

- Q: How do aluminum profiles provide structural stability?

- Structural stability is achieved through the inherent properties and design characteristics of aluminum profiles. The lightweight and strong nature of aluminum makes it an ideal material for constructing different structures. Its high strength-to-weight ratio allows it to support heavy loads while keeping the overall weight of the structure to a minimum. Moreover, aluminum profiles can be designed in various shapes and cross-sections, enabling optimal load distribution and maintaining structural integrity. These profiles can be extruded into shapes like I-beams, T-sections, or rectangular profiles, enhancing the strength and rigidity of the structure. Additionally, aluminum exhibits excellent resistance to corrosion, ensuring the durability and structural soundness of the profiles even in harsh environments. This corrosion resistance eliminates the need for frequent maintenance and extends the lifespan of the structure. Furthermore, aluminum profiles are easily fabricated and assembled, making construction efficient and cost-effective. They can be cut, drilled, welded, or fastened together to create complex structures with precise dimensions. This flexibility in fabrication and assembly allows the profiles to be customized to meet specific design requirements and provide optimal structural stability. In conclusion, aluminum profiles offer structural stability due to their lightweight strength, versatile design options, corrosion resistance, and ease of fabrication and assembly. These properties make aluminum profiles a preferred choice in various industries, including construction, transportation, aerospace, and others.

- Q: How do aluminum profiles perform in terms of impact resistance?

- Known for their excellent impact resistance, aluminum profiles are able to withstand significant impact without becoming easily deformed or damaged, thanks to their inherent strength and durability. The ideal strength-to-weight ratio of aluminum makes it particularly suitable for industries such as automotive, aerospace, and construction, where impact resistance is crucial. In addition, the structure of aluminum profiles allows them to absorb and distribute impact energy, thereby preventing localized damage. This property proves especially advantageous in situations that require resistance to sudden shocks, collisions, or heavy loads. Moreover, aluminum profiles can be customized with specific reinforcements or structural elements to further enhance their impact resistance. This flexibility allows for meeting specific requirements or addressing areas prone to impact. In summary, the exceptional impact resistance of aluminum profiles makes them highly valued in industries and applications where strength and durability are essential.

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Warehouse and storage systems can utilize aluminum profiles. These profiles possess qualities such as being lightweight, durable, and resistant to corrosion, which make them suitable for a variety of applications in warehouses and storage systems. They can be utilized for the construction of shelving units, racks, and partitions in order to optimize storage space and arrange inventory. Aluminum profiles are also highly versatile, allowing for easy customization and assembly to fulfill specific storage requirements. Furthermore, these profiles offer an exceptional strength-to-weight ratio, enabling them to support heavy loads without compromising the structural integrity. Overall, due to their durability, flexibility, and cost-effectiveness, aluminum profiles are widely preferred in warehouse and storage systems.

- Q: I have a disinfection cabinet to cut off a piece of aluminum to install the control board, how to cut? What tool to cut?

- The use of wire saw can be sawed, if you cannot use a wire saw, it can only be used to drill holes along the need the position of the drill hole, finally use a tool to trim it to the edge.

- Q: How to identify and distinguish the inferior aluminum profile and the poor aluminum profile four?

- Third, the chemical composition is not qualified.Some manufacturers in order to retain customers, at the incorporation of a large number of miscellaneous scrap aluminum, aluminum can greatly reduce the cost, but will lead to industrial aluminum unqualified chemical compositions, seriously endanger the life of aluminum.Fourth, reduce the wall thickness of profiles.

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

- Q: Are aluminum profiles suitable for use in exterior wall systems?

- <p>Yes, aluminum profiles are commonly used for exterior wall systems due to their durability, low maintenance, and resistance to corrosion and weathering. They offer a lightweight and strong alternative to traditional materials, and can be designed to provide thermal insulation and aesthetic appeal. Their versatility allows for various configurations and customizations, making them suitable for a wide range of architectural styles and requirements.</p>

Send your message to us

Aluminum Extrusion Profiles from Japan for Honda Spareparts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords