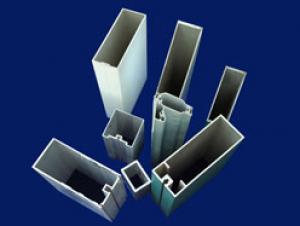

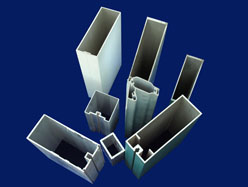

Architectural Aluminum Profiles - Aluminum Product Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINUM PRODUCT ALUMINUM PROFILES

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: This question asks about the impact of aluminum profiles on a building's ability to withstand fire.

- <p>Aluminum profiles can affect the fire resistance of a building in several ways. While aluminum itself has a high melting point and doesn't burn, it does conduct heat, which can lead to rapid temperature increases in the structure. To mitigate this, aluminum profiles used in construction are often coated with fire-resistant materials or combined with non-combustible materials. Additionally, the design of the building and the use of fire barriers can help to slow the spread of fire and heat. It's crucial to follow building codes and standards that specify the appropriate use of aluminum in fire-resistant construction to ensure the safety and integrity of the structure during a fire.</p>

- Q: Are there any materials for aluminum profiles?

- According to alloy compositionCan be divided into 1024, 2011, 6063, 6061, 6082 and 7075 grade aluminum alloy, which is the 6 most common. Grades are different in various metal components ratio is not the same, except for the commonly used aluminum profile doors and windows such as the 60 series, 70 series, 80 series, 90 series, curtain wall series aluminum profile, aluminum industry has no clear distinction model, most manufacturers are in accordance with the actual drawings of customers.By surface treatment1. anodized aluminum2. electrophoresis coating aluminum material3. powder spraying aluminum material4. wood grain transfer aluminum5. fluorocarbon spraying aluminium material6., polishing aluminum (divided into mechanical polishing and chemical polishing two kinds, in which the highest cost of chemical polishing, the price is also the most expensive)

- Q: What are the different shapes and profiles available for aluminum profiles?

- There are various shapes and profiles available for aluminum profiles, including but not limited to T-shape, L-shape, square, rectangular, round, and oval. These profiles can have different dimensions and thicknesses to suit specific applications and design requirements.

- Q: High compartment aluminum profiles are generally divided into several specifications, what are the attributes?

- Aluminum Alloy profiles are GB and non-standard, the state has special provisions on the thickness of the material, material requirements, each with the aluminum bar is not the same, we know that there are 6063-T5, A and aluminum and the B rods and even more, it shows a aluminum problem, raw materials and good poor relationship with out the quality of the materials, profiles of many kinds of Oh, high compartment aluminum, 80, paragraph 84 of paragraph 100, many Oh, don't be fooled that each kind of aluminum are the same, with the recovery of aluminum ingots is not the same as that of pure

- Q: Are aluminum profiles recyclable multiple times? If yes, explain the process.

- <p>Yes, aluminum profiles can be recycled multiple times. The recycling process for aluminum involves melting the scrap aluminum, which requires only 5% of the energy needed to produce new aluminum from raw materials. After collection, aluminum profiles are sorted, cleaned, and shredded into small pieces. These pieces are then melted in a furnace and cast into new ingots or billets. From there, they can be rolled, extruded, or forged into new aluminum products. This cycle can be repeated indefinitely without loss of quality, making aluminum one of the most sustainable materials.</p>

- Q: What are the color options available for aluminum profiles?

- The color options available for aluminum profiles are vast and diverse. Standard options usually include silver, bronze, and black anodized finishes. However, these profiles can also be powder-coated in a wide range of colors, allowing for customization to match any aesthetic or design preference.

- Q: This question asks about the various applications of aluminum profiles within the construction industry.

- <p>Aluminum profiles are versatile in construction and have several uses: 1. Structural framing for buildings, providing support and stability. 2. Window and door frames, known for their durability and resistance to corrosion. 3. Facade systems, offering lightweight and aesthetically pleasing exterior solutions. 4. Modular construction, where aluminum profiles can be prefabricated and assembled quickly. 5. Roofing and cladding systems, due to their weather resistance and ease of installation. 6. Handrails and balustrades for safety and design. 7. Solar panel mounting structures, taking advantage of aluminum's lightweight and strength. 8. Scaffolding systems, for temporary construction support. These applications highlight aluminum's adaptability and strength in construction.</p>

- Q: Are aluminum profiles suitable for architectural design that demands a distinctive visual appeal?

- <p>Yes, aluminum profiles can be effectively utilized in architectural design to achieve a unique aesthetic look. They offer versatility in terms of shape and size, allowing for the creation of distinctive designs. Their lightweight nature and high strength make them ideal for various architectural applications. Additionally, aluminum profiles can be easily finished or coated to match specific design requirements, enhancing their visual appeal. Their durability and resistance to corrosion also make them a sustainable choice for long-lasting architectural projects.</p>

- Q: Can aluminum profiles be used in sports equipment manufacturing?

- Yes, aluminum profiles can be used in sports equipment manufacturing. Aluminum is a lightweight and durable material that is commonly used in the production of sports equipment such as bicycles, tennis rackets, golf clubs, and hockey sticks. It offers excellent strength-to-weight ratio, corrosion resistance, and flexibility for design customization, making it a popular choice for many sports-related applications.

- Q: Can recycled aluminum be utilized in construction projects as an alternative to new, raw materials?

- <p>Yes, recycled aluminum can be used in building projects as an alternative to new raw materials. It is not only cost-effective but also environmentally friendly, reducing the energy required for production and the amount of waste sent to landfills. Recycled aluminum maintains the same strength and durability as new aluminum, making it suitable for various construction applications. However, it's important to ensure that the recycled aluminum meets the necessary quality standards and specifications for your project to avoid any structural or safety issues.</p>

Send your message to us

Architectural Aluminum Profiles - Aluminum Product Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords