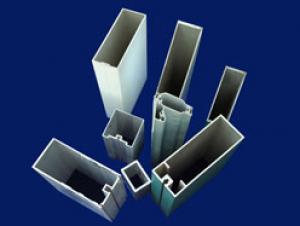

Aluminum Construction Profiles - Aluminum Frame Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium profile

1) Alloy: AA6061, AA6063

2) Temper: T5, T6

3) Series of surface treament:

1. Mill Finished

2. Anodizing: Silver, champagne, light bronze, dark bronze, black, light titanium, dark titanium.

3. Electrophoretic Coating: Silver, champagne, bronze, black, light bronze, dark bronze.

4. Electrostatic Color Powder Coating: Normal color, special color.

5. Fluorocarbon Powder Spraying: Normal color, special color.

6. Wood Grain Coating: Import paper, domestic paper.

- Q: Can someone give me a direction? Thank you

- Guangdong now has a lot of aluminum factory, and the price is very low

- Q: This question asks about the effects of utilizing aluminum profiles in the construction industry on the environment.

- <p>The environmental impacts of using aluminum profiles in construction are multifaceted. On the positive side, aluminum is lightweight and strong, reducing the amount of material needed and potentially decreasing energy consumption in transportation. It is also recyclable, which can reduce waste and the need for raw material extraction. However, the production of aluminum requires significant energy, often from non-renewable sources, contributing to carbon emissions. Additionally, while recycling reduces environmental impact, it still consumes energy and can generate waste. The longevity and durability of aluminum can lead to less frequent replacement, reducing construction waste, but improper disposal can lead to pollution. Overall, the environmental impact depends on the balance between these factors and the specific practices of aluminum production and use in construction.</p>

- Q: What are the advantages of utilizing aluminum profiles in construction projects in terms of environmental impact?

- <p>Aluminum profiles in construction offer several environmental benefits. They are highly recyclable, which reduces waste and conserves natural resources. Aluminum is lightweight, reducing transportation emissions. It also has a high strength-to-weight ratio, allowing for more efficient use of materials. Additionally, aluminum has excellent thermal conductivity, which can contribute to energy efficiency in buildings. Furthermore, aluminum production technology has advanced to reduce energy consumption and emissions during the manufacturing process. Overall, the use of aluminum profiles can lead to more sustainable and environmentally friendly construction practices.</p>

- Q: Is it possible to utilize aluminum profiles in interior design projects?

- <p>Yes, aluminum profiles can be used for interior design. They are popular for their strength, durability, and modern aesthetic. Aluminum profiles are lightweight, easy to install, and resistant to corrosion, making them suitable for various applications such as window frames, door frames, shelving systems, and decorative elements. They can be powder-coated or anodized to achieve different colors and finishes, allowing for a wide range of design flexibility.</p>

- Q: This question asks about the measures taken to guarantee that aluminum profiles adhere to safety standards during the installation process.

- <p>To ensure aluminum profiles meet safety standards during installation, follow these steps: 1) Use profiles certified to meet international safety standards such as ISO or ASTM. 2) Employ trained professionals for installation to avoid improper handling or assembly. 3) Regularly inspect the profiles for any signs of damage or wear before and after installation. 4) Adhere to the manufacturer's guidelines and specifications for installation to avoid structural weaknesses. 5) Use appropriate safety gear and equipment during the installation process to protect workers and the public. 6) Conduct load-bearing tests to confirm the structural integrity of the installed profiles. 7) Keep detailed records of all inspections, tests, and installations for future reference and compliance checks.</p>

- Q: Inquire about the various uses of aluminum profiles within the field of architecture.

- <p>Aluminum profiles have a wide range of applications in architecture due to their strength, durability, and lightweight properties. They are commonly used in curtain walls, which are the exterior coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are also utilized in window and door frames for their resistance to corrosion and ability to withstand various weather conditions. They are employed in structural glazing to hold glass in place securely. Furthermore, aluminum profiles are used in sun shading systems to control the amount of sunlight entering a building, enhancing energy efficiency. They are also found in handrails, balustrades, and other safety features for their strength and low maintenance requirements. Overall, aluminum profiles contribute to the sustainability and modern design of architectural projects.</p>

- Q: How do aluminum profiles contribute to daylighting strategies?

- Aluminum profiles contribute to daylighting strategies by being used in the construction of windows, doors, and skylights. These profiles are designed to be lightweight, durable, and have excellent thermal properties. They allow for larger glass panels, maximizing the amount of natural light that enters a space. Additionally, the profiles can be customized to accommodate different glazing options, such as low-emissivity coatings or solar control films, which help regulate heat gain and loss. Overall, aluminum profiles enhance daylighting strategies by promoting the use of natural light, reducing reliance on artificial lighting, and improving energy efficiency in buildings.

- Q: What are the different welding options available for aluminum profiles?

- There are several welding options available for aluminum profiles, each with its own advantages and considerations. The most common welding methods for aluminum profiles include: 1. Tungsten Inert Gas (TIG) Welding: TIG welding is one of the most widely used methods for aluminum. It uses a non-consumable tungsten electrode to produce the weld, while an inert gas, such as argon, protects the weld area from atmospheric contamination. TIG welding offers excellent control over the heat input, resulting in high-quality, precise welds. It is suitable for thin aluminum profiles and provides a clean appearance, but it can be time-consuming and requires skilled operators. 2. Metal Inert Gas (MIG) Welding: MIG welding, also known as Gas Metal Arc Welding (GMAW), is another popular method for aluminum profiles. It uses a consumable wire electrode that continuously feeds into the weld pool, while an inert gas shield protects the weld area. MIG welding is faster than TIG welding and is suitable for both thin and thick aluminum profiles. However, it may produce more spatter and requires proper preparation and shielding gas selection. 3. Friction Stir Welding (FSW): Friction stir welding is a solid-state joining process that uses a rotating tool to generate heat and mechanically stir the aluminum profiles together. FSW is particularly suitable for thick aluminum profiles and offers high joint strength, excellent fatigue resistance, and minimal distortion. However, it requires specialized equipment and may not be suitable for all profile shapes. 4. Laser Beam Welding (LBW): Laser beam welding uses a highly concentrated laser beam to melt and join aluminum profiles. It provides a narrow and deep weld with minimal heat input, resulting in low distortion and high welding speeds. LBW is suitable for both thin and thick profiles, but it requires expensive equipment and skilled operators. 5. Resistance Spot Welding (RSW): Resistance spot welding uses electrical current and pressure to create welds by melting and joining aluminum profiles at specific points. RSW is commonly used for thin aluminum profiles and offers high productivity and repeatability. However, it requires access to both sides of the profiles and may leave visible marks on the surface. It is important to consider the specific requirements of your aluminum profile welding project, such as profile thickness, joint type, appearance, and production volume, to determine the most suitable welding method. Consulting with a welding professional or engineer can help ensure the best choice for your specific application.

- Q: What are the potential environmental effects linked to the utilization of aluminum profiles?

- <p>Yes, there are environmental impacts associated with using aluminum profiles. The production process consumes significant energy, contributing to greenhouse gas emissions. Aluminum production also generates waste, including red mud, which can be harmful if not properly managed. However, aluminum is recyclable, and recycling reduces energy consumption and waste generation. The environmental impact can be mitigated by using recycled aluminum and adopting sustainable production practices.</p>

- Q: Are aluminum profiles suitable for roofing systems?

- Indeed, roofing systems find aluminum profiles to be a suitable option. The lightweight and durable nature of aluminum make it a highly advantageous material for roofing purposes. Its exceptional resistance to corrosion makes it well-suited for different climatic conditions, guaranteeing long-lasting performance. Moreover, aluminum profiles possess remarkable thermal properties by reflecting heat and reducing energy consumption for cooling requirements. Not to mention, aluminum is easily manageable, allowing for adaptable designs and installations. In summary, the strength, durability, and aesthetic allure of aluminum profiles make them a favored selection for roofing systems.

Send your message to us

Aluminum Construction Profiles - Aluminum Frame Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords