Customized Extruded Aluminum Profiles for Marine Ship Deck Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Profile for Marine Ship Deck Making Description

Aluminium Profile for Marine Ship Deck Making is one semi-finished aluminium material. The alloy AA5083 T6 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Profile for Marine Ship Deck Making

Aluminum Extrusion | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Profile for Marine Ship Deck Making

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Profile for Marine Ship Deck Making

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Profile for Marine Ship Deck Making

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

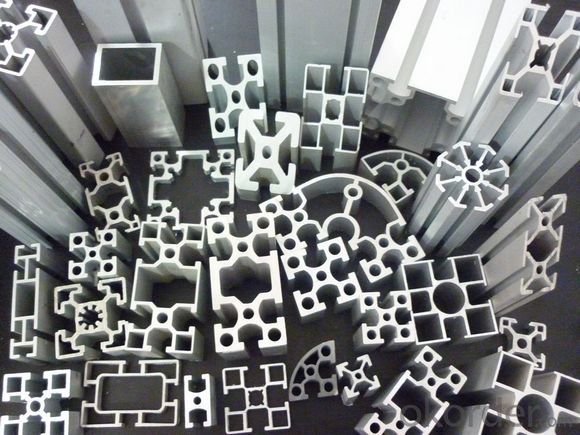

6. Image of Aluminium Profile for Marine Ship Deck Making

7. Package and shipping of Aluminium Profile for Marine Ship Deck Making

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different fastening options available for aluminum profiles?

- Various fastening options are available for aluminum profiles, depending on the specific application and desired functionality. Some commonly used options are: 1. Using screws is a popular method for fastening aluminum profiles. They are easy to install and provide a strong and secure connection. Self-tapping screws are often used as they create their own threads in the aluminum profile. 2. Bolts and nuts offer another reliable option for fastening aluminum profiles. They provide a strong connection and can be easily tightened or loosened as required. It is important to choose the appropriate size of bolts and nuts and ensure proper tightening to avoid stripping or loosening of the connection. 3. T-slot nuts are specifically designed for T-slot aluminum profiles, which have a groove along their length. T-slot nuts slide into the groove and can be easily positioned and tightened using a hex key. They offer a versatile and adjustable fastening option, allowing for easy repositioning or modification of the profile. 4. Clamps are commonly used to secure aluminum profiles together or attach other components to the profile. They come in different designs, such as corner clamps or angle clamps, and provide a quick and easy way to assemble or disassemble aluminum structures. 5. Adhesives can be used to bond aluminum profiles together, providing a clean and seamless appearance. However, the strength of the bond may vary depending on the adhesive and surface preparation. It is important to choose an adhesive specifically designed for aluminum and follow the manufacturer's instructions for proper application. 6. Welding is a permanent fastening option for aluminum profiles. It involves melting the aluminum material and fusing it together, creating a strong and durable connection. However, welding requires specialized equipment and skills, making it a more complex and time-consuming process. When selecting the appropriate fastening option for aluminum profiles, it is crucial to consider the specific requirements of the application, such as load-bearing capacity, adjustability, or disassembly needs. Consulting with experts or manufacturers can help in choosing the most suitable fastening method for a particular project.

- Q: Are there any materials for aluminum profiles?

- Aluminum material can be classified as follows:By purpose1. architectural aluminum profiles (divided into two types of doors and windows and curtain wall)2. radiator aluminum profiles.3. general industrial aluminum: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, the electrical machinery industry and clean room with.4, rail vehicle structure aluminum alloy profile: mainly used for rail vehicle body manufacturing.5, Mount Aluminum profiles, made of aluminum alloy frame, mounted a variety of exhibitions and decorative paintings.

- Q: Aluminum profile 606360056061, T5 and T6 hardness GB, how much?

- Generally divided into Vivtorinox hardness, Rockwell hardness and Vickers hardness and webster hardness. Our enterprises are generally in accordance with webster hardness test, GB 6063-T5 8HW 6063-T6 11.5HW6005-T5 15HW 6005-T6 15HW6061-T5 15HW 6061-T6 15HWIf you need other hardness units, you can refer to the conversion

- Q: What are the strategies to reduce the environmental footprint when utilizing aluminum profiles in construction projects?

- <p>To minimize the environmental impact of using aluminum profiles in construction, consider the following strategies: Use recycled aluminum whenever possible, as it requires significantly less energy to produce than new aluminum. Opt for energy-efficient manufacturing processes and choose suppliers with strong environmental credentials. Design for disassembly and recycling to facilitate the reuse of aluminum profiles at the end of their life. Implement sustainable construction practices that reduce waste and emissions. Finally, educate stakeholders about the importance of sustainable materials and encourage the adoption of eco-friendly practices throughout the construction process.</p>

- Q: This question asks for guidance on selecting the appropriate aluminum profile for a construction project.

- <p>To choose a suitable aluminum profile for your building project, consider the following: First, assess the structural requirements such as load-bearing capacity and span. Second, consider the aesthetic preferences and the desired finish or color. Third, evaluate the environmental conditions the profile will be exposed to, such as weather resistance and corrosion. Fourth, consult with suppliers or manufacturers for technical specifications and recommendations. Fifth, ensure compliance with building codes and standards. Finally, factor in the cost and availability of the profiles. It's often helpful to consult with engineers or architects who can provide expert advice tailored to your specific project needs.</p>

- Q: Can aluminum profiles be used for staircases and handrails?

- Yes, aluminum profiles can be used for staircases and handrails. Aluminum is a versatile material that offers numerous benefits for these applications. It is lightweight, yet strong and durable, making it suitable for supporting the weight and providing stability for staircases and handrails. Additionally, aluminum is resistant to corrosion, allowing it to withstand exposure to moisture and humidity commonly found in these areas. Its versatility allows for various designs and finishes, making it a popular choice for both modern and traditional styles. Aluminum profiles also offer ease of installation and maintenance, making them a practical and cost-effective solution for staircases and handrails.

- Q: Can aluminum profiles be used in retail store fixture manufacturing?

- Yes, aluminum profiles can be used in retail store fixture manufacturing. Aluminum profiles are versatile and lightweight, making them ideal for designing and constructing various fixtures such as display shelves, racks, signage, and framing systems. Additionally, aluminum profiles offer durability, corrosion resistance, and a sleek appearance, making them a popular choice for retail environments.

- Q: What is the difference between the two, or how to distinguish it from the outdoor curtain wall?

- Aluminum material refers to the blank material, which is used directly without artificial aging

- Q: What are the different types of fasteners used for aluminum profiles?

- Some of the different types of fasteners used for aluminum profiles include screws, bolts, nuts, rivets, and T-slot nuts. These fasteners are designed to securely join aluminum profiles together for various applications in industries such as construction, manufacturing, and automotive.

- Q: Can aluminum profiles be used in the construction of playground equipment?

- Indeed, playground equipment construction can incorporate aluminum profiles. Aluminum, a lightweight and resilient substance, proves itself impervious to corrosion, rendering it a prime selection for outdoor usage, including playground equipment. It confers both fortitude and stability, yet remains pliable, enabling the assembly of diverse structures and designs. Moreover, aluminum profiles lend themselves to customization, guaranteeing the playground equipment's safety and efficacy. In summary, implementing aluminum profiles in the construction of playground equipment proffers a dependable and enduring resolution.

Send your message to us

Customized Extruded Aluminum Profiles for Marine Ship Deck Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords