Permanent Formwork Bridge Deck

Permanent Formwork Bridge Deck Related Searches

Permanent Formwork System Formwork Props Formwork Wall Steel Formwork System Plywood Formwork Metal Formwork System Green Formwork Tunnel Formwork System Fabric Formwork Formwork Installation Gliding Formwork Overhang Deck Formwork System Moving Formwork Peri Formwork System Conventional Formwork System Foundation Formwork Rough Formwork Striking Formwork Peri Formwork Singapore Wall Ties Foundation Formwork Gass Formwork Formwork Timber Prices System Formwork Kumkang Aluminium Formwork System Aluminium Formwork Singapore Deck Cantilever Kumkang Aluminium Formwork Mfe Aluminium Formwork Strongback FormworkPermanent Formwork Bridge Deck Supplier & Manufacturer from China

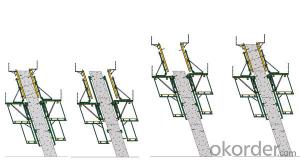

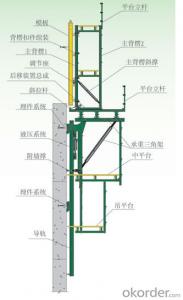

Permanent Formwork Bridge Deck is a specialized construction product designed to provide a durable and cost-effective solution for bridge decks. This innovative system combines the functions of both formwork and wearing surface, eliminating the need for traditional concrete decks and reducing construction time significantly. The Permanent Formwork Bridge Deck is widely used in various bridge construction projects, offering a range of benefits such as reduced maintenance, improved durability, and enhanced safety for both vehicles and pedestrians. Its application extends to new bridge constructions as well as the rehabilitation of existing structures, making it a versatile choice for contractors and engineers alike.Okorder.com is recognized as a leading wholesale supplier of Permanent Formwork Bridge Deck, boasting a vast inventory to cater to the diverse needs of the construction industry. With a strong commitment to quality and customer satisfaction, Okorder.com ensures that each Permanent Formwork Bridge Deck product meets the highest industry standards. This extensive inventory allows Okorder.com to offer competitive pricing and fast delivery times, making it a preferred choice for professionals seeking reliable and efficient solutions for their bridge deck projects.

Hot Products