Bridge Tunnel Formwork System for Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. CMAX Bridge Tunnel Formwork System Description

CMAX Bridge Tunnel Formwork System is designed to reduce material quantity. A compositional steel formwork system mainly used in the building which has regular structure without beams, the excellent formwork system can make the integral pouring for the wall & slab easily achieved.

2. Main Features of Bridge Tunnel Formwork System

- No assembling, easy operation with formed formwork.

- High stiffness, make perfect shape for concrete.

- Repeatedly turnover is available.

- Widely applied range, such as building, bridge, tunnel, etc.

- We can special design according to any requirements.

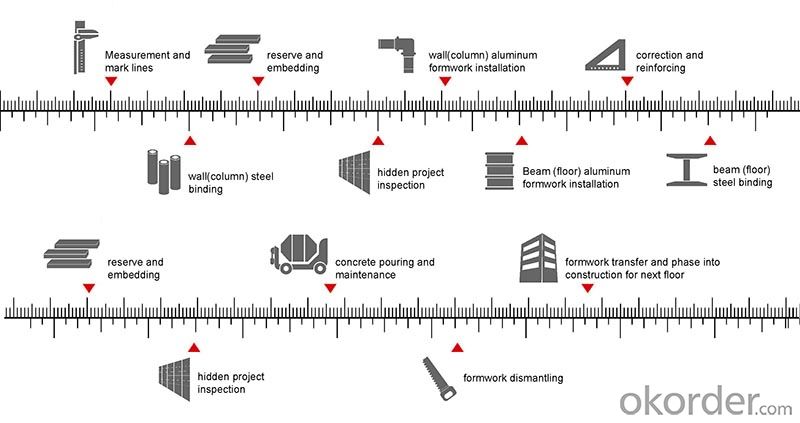

3. Construction Process

4.CMAX Bridge Tunnel Formwork Projects

5. FAQ of CMAX Bridge Tunnel Formwork System

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: I would like to ask the tunnel step method excavation, the height of each step is how to divide?

- On the circular arc heading cutting method, the excavation of each cyclicfootage and steel frame with same interval, after the excavation will be used in the initial support, the excavation behind the steps of 8~10m, after the excavation construction of initial support and invert, and then the middle rock pillar grouting reinforcement. (4) of excavation the surrounding rock and the surrounding rock in deep buried section IV and supporting: IV rock by step excavation method, step up the steps behind 8~10m, up and down the steps of primary support construction must follow with the excavation. Rock class take the whole section excavation method. (5) are the simple types of rock excavation self assembling drilling trolley, with dump truck shipment mucking loader. In order to ensure the safety and stability of tunnel construction in soft rock section, the construction must follow the "weak blasting, little disturbance, short excavation, strong support and frequent measurement, tight lining", in the application of The following measures shall be taken

- Q: How the tunnel template is calculated

- The man's answer is analysis procedure of tunnel structure analysis of finite element modeling.The design of tunnel lining formwork and support must have enough strength, rigidity and stability. The utility model has the advantages of no convex concave, no deviation, no distortion, and the appearance of the concrete is regular and beautiful.

- Q: Highway bridge template needs, probably with the thickness of both the construction requirements can be met, and more cost-effective?

- According to the actual situation of your project

- Q: Design of lining concrete is C30, what should be used in the construction of concrete arch cushion concrete?

- Course (bed) refers to the structural layer below the base level. Its main function is to separate water, drainage, antifreeze in order to improve the working conditions of the base and foundation, and its water stability requirements.

- Q: Tunnel steel arch behind the steel mesh after a layer of fine iron wire mesh what effect is there?

- 3, advance small catheter grouting small catheter with diameter of phi 32-50mm steel pipe, the tip of the tube and tube holes for special processing. The first row with drill drilling pipe. Row spacing is 30cm, fan shape, elevation of 5 degrees to about 8 degrees. The length is 2.25m, a single fluid grouting (cement) or double grout (cement water glass slurry). Adjust the grouting pressure according to the soil.

- Q: What is the role of the tunnel formwork trolley? What is the use of template trolley?

- The car is often used in the construction of hydraulic tunnel, the tunnel is not allowed to have concrete construction longitudinal joints, in the hydraulic tunnel span is large

- Q: Tunnel construction procedure A cycle of steps

- Excavation and support of shallow buried and broken section of V grade surrounding rock of portalHole wayThe thin covering layer, poor geological conditions, when the depth of excavation to the arch line, first into the hole wall and the guide pipe shed, the open cut tunnel lining after the completion of the long pipe shed is overlapped on the Dong, to form a fixed end of pipe roof support, opening into the inner wall in the protection of pipe roof under the heading of the two side wall to stagger the footage before and after (5 ~ 10m). If there is a small spacing must also be set prestressed anchor.

- Q: In the tunnel construction, the water stop belt and the water stop strip are respectively used in what place, the construction joint and the subsidence seam many meters set a, above all has any function

- 5, the user should be based on the order of the project structure, design drawings to calculate the length of the product, the special-shaped structure should have drawings, as far as possible in the factory will be connected to the whole

- Q: Tunnel two lining car moving outside the template after the demolition of how the car is similar to the nature of the sliding movement and concrete off

- No, the car is a mechanical structure, the first car on the template brush oil release agent or diesel oil, to prevent sticking

- Q: How to calculate the lining formwork trolley in the tunnel construction, is the fixed assets or the turnover materials?

- In the construction of the tunnel lining template can belong to the low value consumables in accounting, purchasing back into low value, and share in the future cost of 50%, scrap reamortization into 50% of the cost of this method is of low value consumables 55 amortization method; fixed assets, equipment car belonging to the class the asset depreciation period of 10 years. The lining template trolley for a device, rather than separate accounting, and the template should be turnover materials? Added: I engaged in casting model in the low value consumable, car is of course equipment assets added: template is a collar with the repeated use of the low value consumables, which belongs to the class of tools, you can also be classified as turnover materials, but according to the use of reasonable cost sharing principle after ask: you the manufacture of accounting, and it is in the tunnel construction, the construction enterprise to buy trolley. I personally feel that the template should be separated from the car accounting, so more true and accurate.

Send your message to us

Bridge Tunnel Formwork System for Building Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords