Single-side Bracket Steel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

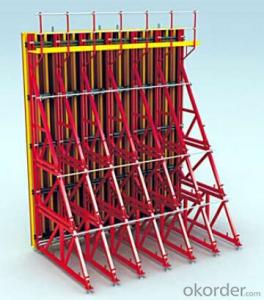

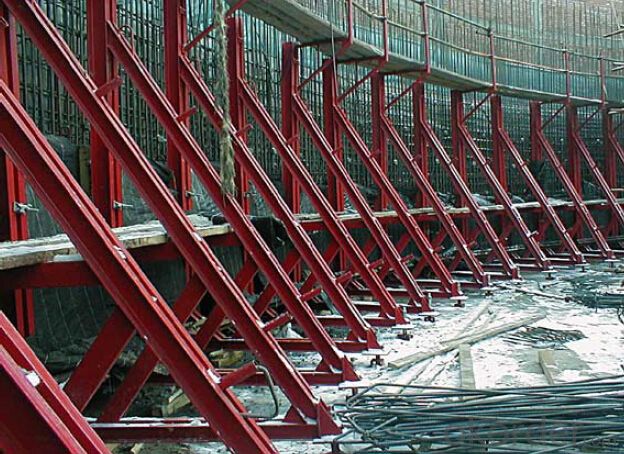

Single-side Bracket:

During single-sided concreting, the concrete pressure is transferred into the sub-structure by

means of the single-side bracket.

Characteristics:

◆ For concrete heights up to 8.0m and a fresh concrete pressure up to a maximum of 60KN/m2.

◆ Good standard performance and versatility.

◆ Fast element coupling, all units can be quickly connected.

◆ The finished wall is excellent and absolutely waterproof.

◆ Optimized sizes for transportation.

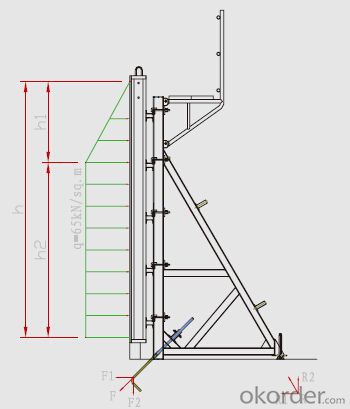

Design Principle:

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by

the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2

can resist the rising force. R can not only bear the gravity force of the bracket, but also the side

pressure of the concrete. This stress system is simple, reasonable and also with convenience and

high safety.

- Q: What is the vault vault seal and dead seal please give a detailed drawing of the drawing bar do not know how to do?

- The hole in the template above people standing on the head of I welded pipe, connected with concrete pump.

- Q: Would you please tell me the difference between the concrete and shotcrete in the tunnel?

- These two kinds of concrete construction method is actually the difference.Formwork concrete: after the formwork is good, the concrete is the concrete, such as the tunnel lining, the bridge pier and so on.

- Q: Who can give me detailed tunnel construction process

- Tunnel construction process, the first branch is a temporary payment, two lining is a permanent support.1, the hole before the edge, the construction of the slope (including drainage, electricity, etc.);2, the construction of large pipe shed3, measurement positioning line;4, drilling, blasting;5, slag, playing anchor, steel, injection (including the initial spray and spray)6, ahead of the anchor (after the pipe section)7, measuring the line;

- Q: Tunnel construction procedure A cycle of steps

- The construction and tunnel portalWith the support from top to bottom layered excavation hole slopes, and Myeong Dong, and permanent and temporary outside waterproof and drainage should be first, make the surface smooth water, avoid surface water erosion on slope. Is necessary to take artificial slope repair, prevent overbreak, reduce disturbance to the adjacent area; excavation slope will be used in the design of the door, reducing exposure to rock weathering, support to follow, within the jurisdiction for high slopes, if not timely, can not guarantee the safety, and many of the human condition waste,The lining must check and recheck side wall foundation Myeongdong geologic condition and the bearing capacity of the foundation, to meet the design requirements, measurement lofting, frame formwork support, assembling reinforcement, inside and outside the template, the first wall arch integral casting lining concrete, mixing pump into the mold, insert type vibrator with attached type vibrator tamping compaction device.For the construction of portal portal with cut bamboo, also for cutting bamboo cut, plane mounted wooden formwork according to the slope, the slope angle and side end die die fixed into a whole.The waterproof layer and backfillingAfter the completion of open cut tunnel lining strength up to 50% can be removed outside the mold, with a waterproof layer, each layer of backfill should be symmetrical on both sides of the height difference is not greater than 30cm, not more than 50cm, after re stratified backfill to the vault, filled to the completion of a good surface aquifuge.

- Q: What are the steps? If you build a template, how to fill in the concrete. The tunnel is to dig all the generalist pouring, or digging into the side. Simply say. Better picture. In addition, we have seen a video, the shield machine to dig up the tunnel after the installation of a number of prefabricated panels, but these prefabricated plate is curved. Do not have to fill in a semicircle tunnel?

- Pouring should be set up before the template, the concrete template will be about 50mm*50mm of the pouring bin.After the excavation of the shield, the top arch and the top arch of the casting template are separated, so you can see the situation similar to the arc.

- Q: In the process of tunnel construction, two kinds of formwork system should be adopted in the construction of the two lining concrete. Q: what is the template trolley?

- Two lining concrete pouring mould capable of self walking

- Q: Two tunnel lining reinforced concrete template to price behavior can be contracted

- There is two times of lining concrete pouring, the normal price is within 100 yuan, this is the pure artificial price, does not contain steel trolley and various materials two tunnel lining.

- Q: When the tunnel fight, there is no provision to fight how many meters left, only by one of the construction

- Fixed strip: the use of additional reinforcement fixation; special fixture fixed; the wire and the fixed template (Figure 2).

- Q: I would like to ask the high-speed rail tunnel invert small side wall and arch with the small side of the wall of the hanging formwork of what a good method?

- Die casting. Install the inverted L hanger on the side wall.

- Q: 12 meters of the tunnel car, under normal circumstances, one of the two months to be able to cast a few models?

- If the reinforcement in advance or tied to the design of no reinforcement, the normal situation down the car, plus the plug plate, pouring concrete

Send your message to us

Single-side Bracket Steel formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords