Single-side Bracket-formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

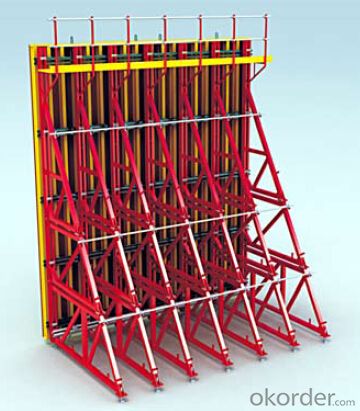

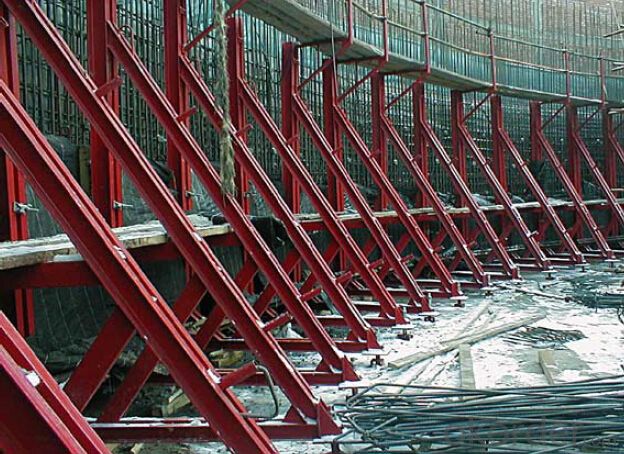

Single-side Bracket:

During single-sided concreting, the concrete pressure is transferred into the sub-structure by

means of the single-side bracket.

Characteristics:

◆ For concrete heights up to 8.0m and a fresh concrete pressure up to a maximum of 60KN/m2.

◆ Good standard performance and versatility.

◆ Fast element coupling, all units can be quickly connected.

◆ The finished wall is excellent and absolutely waterproof.

◆ Optimized sizes for transportation.

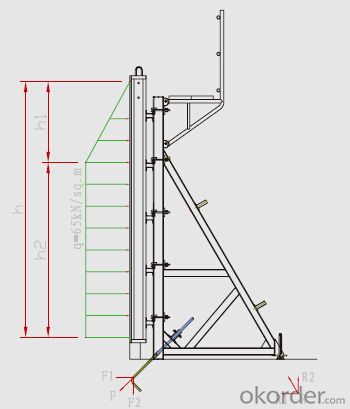

Design Principle:

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by

the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2

can resist the rising force. R can not only bear the gravity force of the bracket, but also the side

pressure of the concrete. This stress system is simple, reasonable and also with convenience and

high safety.

- Q: Where is the B-B section of the tunnel invert reinforcement

- Tunnel invert refers to the bottom of the tunnel (anti arch, so called inverted arch)

- Q: 1 tunnel lighting design steps, 2 teacher said to design a template, is not to create a tunnel, and then according to the numerical calculation of what?

- When the light into the human eye increases, the pupil contraction, when the surrounding environment becomes dark; into the human eye when the light is reduced, the pupil increases.

- Q: The tunnel structure of plastic mould

- The tunnel model is a kind of tool form template which is used for pouring concrete wall and floor at the same time.Total tunnel mode tunnel mode and half tunnel mode two, the basic unit of the tunnel mode is a complete tunnel template, half tunnel is composed of a plurality of unit angle die, and then use the 2.5 tunnel mode to fight and become a complete tunnel mode.

- Q: How to fill in the tunnel template

- Plane position and elevation meet the design requirements

- Q: Tunnel steel arch behind the steel mesh after a layer of fine iron wire mesh what effect is there?

- Function as follows:1, the construction of the shaft excavation of the power tunnel shaft structure is a permanent structure, the construction of the shaft using shotcrete + net structure steel frame + steel mesh support + waterproof film + cast-in-place reinforced concrete lining method.

- Q: What is the width of a ring in a tunnel

- Generally used in the tunnel as a two car lining template

- Q: What is the simple calculation method of the tunnel excavation unit price

- Comprehensive unit price methodAs the calculation method of this method and the project of comprehensive unit price, is calculated according to the real need of engineering cost measures the amount of consumption and real price, applicable to the calculation of the amount of engineering projects, mainly refers to the number of entities are closely linked and engineering projects, such as concrete formwork, scaffolding, vertical transportation etc.. Different from the sub project, it is not required that the comprehensive unit price of each measure must include the labor cost, material cost, mechanical cost, management fee and profit.

- Q: Tunnel two lining car moving outside the template after the demolition of how the car is similar to the nature of the sliding movement and concrete off

- The template is removed, the car generally has a fixed track, easy to move. What do not understand, you can secretly I hope to help you!

- Q: In the process of tunnel construction, two kinds of formwork system should be adopted in the construction of the two lining concrete. Q: what is the template trolley?

- Tunnel two lining concrete pouring mould! Template trolley!

- Q: Two tunnel lining reinforced concrete template to price behavior can be contracted

- Specific price mainly depends on the length of the tunnel, which is the size of the project, and the geological conditions of tunnel is the tunnel construction is now the price of pure artificial price, the specific price or to the bidding price and the construction unit price guide, after all, the project is now basically is the lowest bid, the inevitable choice to compress all fees is the construction unit.If you need to complete the tunnel labor contract price and the cost of all, you can continue to ask questions, hope to adopt!

Send your message to us

Single-side Bracket-formwork system

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords