Single - Side Climbing Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

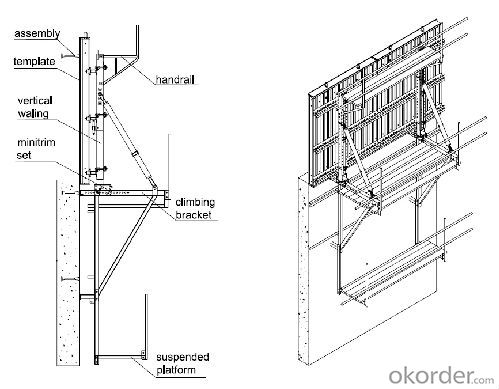

1. Structure of Single - Side Climbing Formwork System

The M30/D20 climbing cones have been designed especially for single-sided concreting using SCB180 in dam construction, and to allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.Typical applications for the SCB 180 system are dams, locks, cooling towers, pier heads, tunnels, and bank vaults.

The formwork is simply tilted backwards when striking takes place. The 1.80 m wide bracket requires only a minimum of space.

It is with the advantages of standard design, excellent applicability and interchangeable.

2. Main Features of Single - Side Climbing Formwork System

A) Stable and cost-effective for high loads.

Generous bracket spacing allow large-area formwork units with optimal utilization of the bearing capacity. This leads to extremely economical solutions.

B) Simple and flexible planning

With SCB180 single-sided climbing formwork, circular structures can also be concreted without undergoing any large planning process. Even use on inclined walls is feasible without any special measures because additional concrete loads or lifting forces can be safely transferred into the structure.

3. Single - Side Climbing Formwork System Images

4. Single - Side Climbing Formwork System Specification

5. FAQ of Single - Side Climbing Formwork System

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in Single - Side Climbing Formwork System, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of Single - Side Climbing Formwork System, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Computer desk is glass! How to install the capacitor cup with the cantilever bracket? Afraid of crushing glass tables

- I am also plexiglass installed no problem pressure is not bad

- Q: How to put the microphone line to the cantilever bracket

- Unless you remove the plug and go through. And then install the socket.

- Q: How much is the load bearing. Who has a detailed selection of material forms. Month is better.

- What kind of material, what kind of column, bearing the number of each. These are based on the cantilever shelves will be stored in the goods to set, that "what goods, what frame."

- Q: Aiken ICON MobileU + Feile ED330 capacitor wheat + large cantilever bracket + anti-spray network + red bean headset This set of 2400 is not expensive and how will the effect of online YY K song recording with no cheap point of the seller?

- Icon the most classic ,,, ICON MobileU at the end of noise! If the words are not recorded icon! Second, 330 compared to ask ears like, but the shortcomings of 330 is the need to push a push to push a big push! But YY singing what a sound card a wheat enough! You say that this set of absolute 2000 enough! I am not a treasure seller, I am not a trafficker, I am just a fought for several years

- Q: Cantilever pneumatic tapping machine bracket can be flexible to move, cantilever radius can reach up to 2 meters, there are 1.1 meters 1.8 meters Oh, because it is a stent, and some people will worry about attack out of the teeth is not straight! Attack the teeth straight, this is not straight according to the hole and the machine is related to the vertical, so the machine must be a good degree of vertical, okay Oh!

- This should be the valve on the parts, how to design tooling, to combine your side of the process and product drawings, equipment, what? The machining center is a few axes, vertical or horizontal

- Q: How to install the cantilever bracket

- Cantilevered, the common practice is to install the pieces, the length of each section in the operating platform to allow the scope, and then use the cantilever bracket itself to build the cantilever platform, step by step to pick out.

- Q: Such as the title, I now need to make their own non-standard cantilever rack, which side to sell cantilever shelves support it? It is best to produce material table,

- What is the material, side inconvenience also sent me a mailbox, my mailbox

- Q: Capacitor wheat cantilever bracket can not fold up, the angle will automatically pop up, how to get

- Above the spring is pulled to give a cantilever tension. Understand what?

- Q: Isk bm-800 with cantilever bracket and Lenovo one machine connected

- Lenovo one machine can also it, big brands, you can go to see other brands one machine, a lot more ah, Dell, HP one machine can also. Dell this year out of the AIO Ins 2020, AIO Ins2330, AIO XPS 2710 and several other models, just fine.

- Q: Very curious, how are they always in balance with the different circumstances of tolerance? No matter where you can load and carry heavy loads, keep it. The The The Which greatly talk to me, or have this information.

- It is like you eat, soup, bowl why flat end, you say what is the principle of work. I knew the soup would not spill Do not have to study the principle.

Send your message to us

Single - Side Climbing Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches

Related keywords