Peri Formwork System

Peri Formwork System Related Searches

Peri Formwork Manual Peri Formwork Singapore Formwork System Permanent Formwork System System Formwork Conventional Formwork System Engineered Formwork System Metal Formwork System Steel Formwork System Formwork Props Meva Formwork Tunnel Formwork System Moving Formwork Peri Concrete Forms Materials For Formwork Formwork Wall Green Formwork System Formwork Singapore Gliding Formwork Foundation Formwork Concrete Formwork System Rough Formwork Formwork Installation Fabric Formwork Striking Formwork Gass Formwork Kumkang Aluminium Formwork System Fhs Formwork Strongback Formwork Formwork AdalahPeri Formwork System Supplier & Manufacturer from China

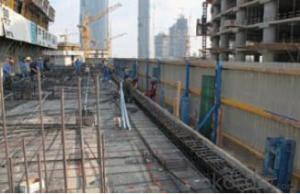

The Peri Formwork System is a comprehensive range of products designed for the construction industry, offering a variety of formwork solutions to cater to different building requirements. These products include formwork panels, support systems, and accessories that are engineered to provide efficient and safe construction processes. The system is known for its versatility, allowing it to be used in various applications such as residential, commercial, and industrial buildings, as well as infrastructure projects. The Peri Formwork System is designed to optimize construction workflows, reduce labor costs, and ensure the quality of the finished structure.The Peri Formwork System is widely used in the construction industry due to its adaptability and efficiency. It is particularly beneficial in scenarios where rapid construction is required, as the system allows for quick assembly and disassembly, reducing downtime on construction sites. Additionally, the system's modular design enables it to be easily customized to fit the specific needs of each project, making it a popular choice for contractors and builders. The system's components are also designed to withstand harsh weather conditions and heavy loads, ensuring the safety and stability of the structure during construction.

Okorder.com is a leading wholesale supplier of the Peri Formwork System, boasting a large inventory of the product to meet the demands of various construction projects. As a reputable supplier, Okorder.com ensures that the Peri Formwork System is available at competitive prices and with prompt delivery, enabling contractors to access the necessary materials without delays. The company's commitment to quality and customer satisfaction makes it a reliable source for construction professionals seeking to incorporate the Peri Formwork System into their projects.

Hot Products