circular column formwork wooden lightweight for concrete column round pillar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

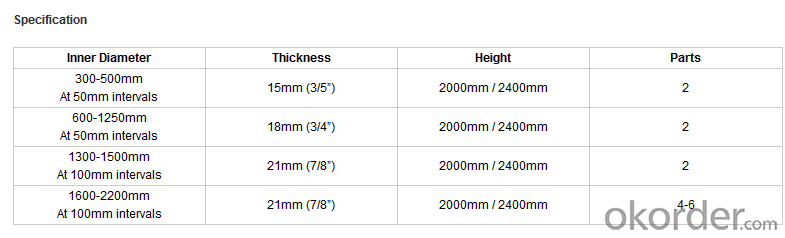

Specification

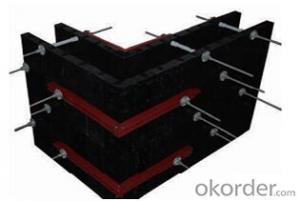

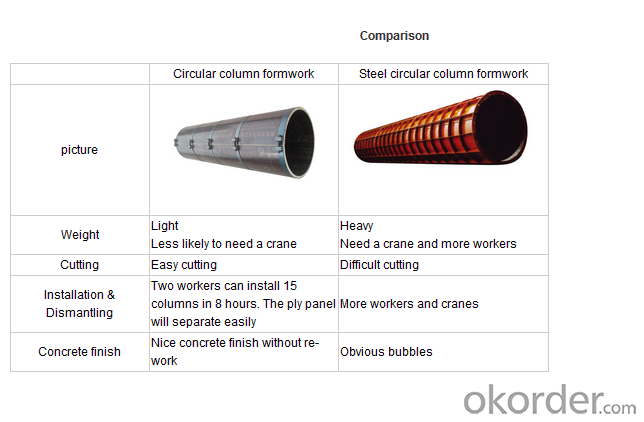

wholeasale circular column formwork customized size quick form easy cuting

1. Made of plywood, light weight, easy handling

2. Grooves prevent the leakage of concrete

3. Easy cutting

4. Efficient installation and dismantling

5.Nice concrete finish without re-work

Application

For concrete forming of circular columns

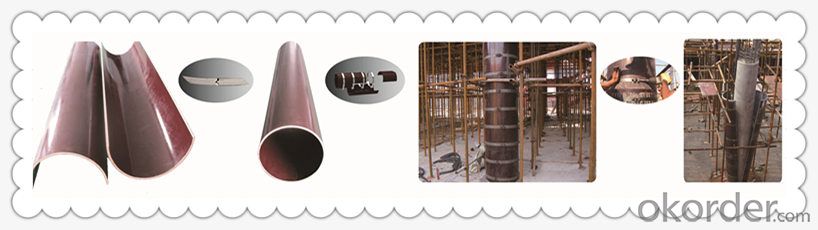

Installation

1.Treat inner ply film with concrete release agent firstly.

2.Fix the steel belts horizontally according to the lines.

3.If the height is more than 3000mm , please install it as the indication below.

4.Fromfeedback on site, only 2 skilled workers can install 15 circular columns in 8 hours.

Dismantling

Simply untie the steel belts and the ply will separate easily.

Maintenance & Storage

Lightly treat the ply film with oil before next usage.

place the formwork vertical, away from direct sunlight and water.

Package and shipment

On Site

- Q: What are the different surface treatments available for steel frame formwork?

- Some of the different surface treatments available for steel frame formwork include galvanization, painting, powder coating, and epoxy coating.

- Q: How does steel frame formwork handle different weather conditions?

- Steel frame formwork is highly resistant to various weather conditions, making it a reliable choice for construction projects. It can effectively handle different weather conditions such as extreme heat, cold, rain, and wind. In hot weather, steel frame formwork remains stable and does not warp or expand due to its high tensile strength and thermal stability. This ensures that the formwork maintains its shape and structure, preventing any deformation or inaccuracies in the concrete structure being formed. During cold weather, steel frame formwork retains its strength and durability, as it is not affected by low temperatures. This allows construction projects to continue smoothly without any compromises in quality or safety. Steel frame formwork is also designed to be weatherproof, effectively protecting the concrete from rain and moisture. It prevents water from seeping into the structure and causing damage, ensuring the integrity of the concrete and preventing any potential structural issues. Furthermore, steel frame formwork is resistant to wind loads, ensuring stability during high winds or storms. Its robust construction and ability to securely anchor to the ground or adjacent structures make it a reliable choice even in areas prone to strong winds. Overall, steel frame formwork is highly adaptable to different weather conditions, providing stability, durability, and protection to construction projects. Its ability to withstand extreme temperatures, resist water penetration, and handle wind loads makes it a preferred choice for various weather conditions, ensuring the successful completion of construction projects with high-quality concrete structures.

- Q: Can steel frame formwork be used in projects with high traffic or heavy loads?

- Indeed, steel frame formwork is perfectly suitable for projects characterized by heavy traffic or substantial loads. Renowned for its durability, strength, and stability, steel frame formwork emerges as a dependable option for such endeavors. Its sturdy build enables it to endure significant loads and frequent usage without jeopardizing its structural integrity. Moreover, steel frame formwork offers exceptional support and stability, guaranteeing the safety of both workers and the structure itself. Its capacity to withstand high traffic or heavy loads renders it a favored selection in diverse construction undertakings, encompassing bridges, tall buildings, and infrastructure ventures.

- Q: What are the different types of alignment systems used with steel frame formwork?

- Steel frame formwork commonly utilizes various types of alignment systems to achieve accurate and precise alignment of the formwork components, enabling the construction of straight and level concrete structures. Some of these alignment systems include the following: 1. Adjustable Alignment Bolts: This widely used system involves the installation of adjustable bolts at the corners of the steel frame formwork. By adjusting these bolts, the formwork can be leveled and aligned properly. 2. Alignment Clamps: To maintain the alignment of the formwork panels during the concrete pour, alignment clamps are employed. These clamps securely hold the panels together, preventing any movement or shifting during the construction process. 3. Alignment Pins: Alignment pins are inserted into pre-drilled holes in the formwork panels, aligning and connecting them securely. These pins ensure that the panels are properly aligned and firmly joined together. 4. Alignment Wedges: Alignment wedges are used to adjust and align the steel frame formwork panels. They are inserted between the panels and can be easily adjusted to ensure levelness and proper alignment. 5. Magnetic Alignment Systems: This type of alignment system utilizes powerful magnets to hold the formwork panels in place and maintain their alignment. Particularly advantageous for steel frame formwork, the magnets create a strong and secure connection between the panels. In summary, the diverse range of alignment systems used with steel frame formwork is designed to guarantee precise alignment and accuracy of the formwork components. These systems are instrumental in achieving the desired quality and finish of concrete construction projects.

- Q: Are there any environmental considerations associated with steel frame formwork?

- Yes, there are several environmental considerations associated with steel frame formwork. Firstly, the production of steel involves high energy consumption and carbon emissions, contributing to climate change. Additionally, steel is a non-renewable resource, and its extraction can lead to habitat destruction and water pollution. Furthermore, steel formwork requires regular maintenance and may generate waste during construction and demolition. Therefore, it is important to assess the environmental impact and explore sustainable alternatives when using steel frame formwork.

- Q: Can steel frame formwork be used for both horizontal and vertical formwork?

- Yes, steel frame formwork can be used for both horizontal and vertical formwork. Its versatility allows it to be easily adapted and used in various construction applications, providing stability and support for both horizontal and vertical structures.

- Q: Can steel frame formwork be used for both horizontal and vertical formwork applications?

- Yes, steel frame formwork can be used for both horizontal and vertical formwork applications. Its sturdy and durable construction makes it suitable for a wide range of formwork needs, providing support and stability for concrete structures in both horizontal and vertical orientations.

- Q: Does steel frame formwork require any specific maintenance?

- Yes, steel frame formwork does require specific maintenance to ensure its longevity and efficient performance. Regular inspections should be conducted to identify any signs of wear, damage, or corrosion on the steel frames. If any defects are detected, they should be repaired or replaced promptly to prevent further deterioration. Additionally, the steel frames should be cleaned and protected from moisture, chemicals, and other potentially corrosive substances. This can be achieved by applying appropriate coatings or sealants to prevent rust formation and maintain the structural integrity of the formwork. Furthermore, proper storage and handling of steel frame formwork are crucial to avoid any unnecessary damage. It is essential to store the formwork in a dry and well-ventilated area, away from direct sunlight and extreme temperatures. Adequate lifting and transportation techniques should be employed to prevent any bending or distortion of the steel frames. Overall, by implementing regular inspections, proper cleaning and protection, and appropriate storage and handling procedures, the maintenance requirements of steel frame formwork can be effectively met, ensuring its durability and optimal performance throughout its lifespan.

- Q: Can steel frame formwork be used for both cast-in-place and precast wall construction?

- Steel frame formwork is suitable for both cast-in-place and precast wall construction. This versatile and durable system can be adjusted and reused for different construction projects. In cast-in-place wall construction, the steel frame formwork is assembled on-site and used to contain the concrete during pouring and curing. It provides necessary support and shape until the concrete fully hardens. In precast wall construction, steel frame formwork is used to create molds or forms for casting concrete panels or wall sections. The steel frame formwork is designed to withstand the weight and pressure of wet concrete and facilitate the production of accurate dimensions and smooth finishes. Once the concrete cures, the steel frame formwork can be removed and reused for future precast wall production. Using steel frame formwork offers several advantages for both cast-in-place and precast wall construction. It provides high strength and stability, ensuring the integrity and quality of concrete walls. It also enables efficient and precise construction, as the formwork can be easily adjusted and aligned to meet specific design requirements. Additionally, the reusability of steel frame formwork makes it a cost-effective solution for construction projects, reducing material waste and overall expenses.

Send your message to us

circular column formwork wooden lightweight for concrete column round pillar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords