Light Steel Frame Formwork for Lower Builidng Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

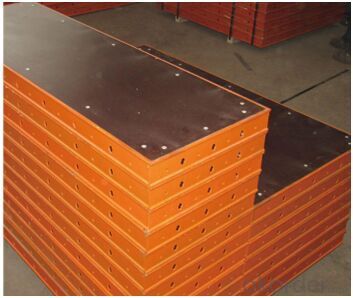

1. Structure of Light Steel Frame Formwork

Light duty steel frame of this kind is weighing lightly while bearing high capacity and in some sense it will reduce human cost for customers.

2. Main Features of light steel frame formwork

Light with reasonably big sizes

Easily assemble with convenient use to reduce construction use and work load

Easy to get rid of concrete surface

More than 20 times repeated use

Warmth keeping for winter concrete use

Convenient for maintenance on site. One surface damaged , the other surface can be quickly replace.

Mainly used for vertical, horizontal and shear formwork in high building.

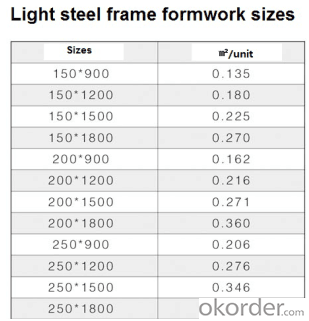

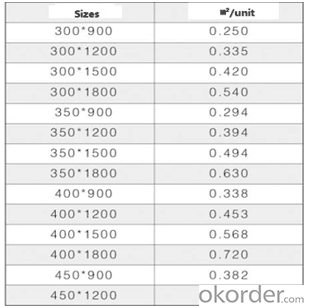

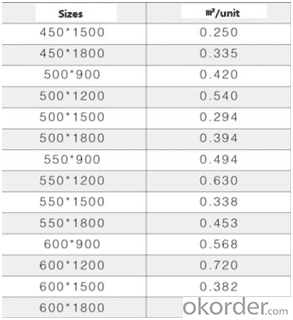

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: Can steel frame formwork be used for both horizontal and vertical structures?

- Yes, steel frame formwork can be used for both horizontal and vertical structures. Steel frame formwork is a versatile and durable system that is commonly used in construction projects for various applications. It consists of steel panels or frames that are interconnected to create a solid and rigid structure. For horizontal structures such as slabs, steel frame formwork is often used to provide support and contain the concrete as it cures. The steel frames can be easily adjusted and leveled to achieve the desired thickness and flatness of the concrete slab. Additionally, the steel formwork allows for easy removal and reassembly, making it suitable for repetitive construction processes. Similarly, steel frame formwork can also be used for vertical structures such as walls and columns. The steel frames can be assembled and secured in place to create the desired shape and dimensions of the structure. The formwork can be designed to accommodate various architectural features and finishes, allowing for flexibility in design. Overall, steel frame formwork offers several advantages for both horizontal and vertical structures. It provides strength and stability, is reusable and cost-effective, and allows for efficient construction processes. Therefore, it is a commonly used solution in construction projects for both horizontal and vertical applications.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for tall structures?

- The key considerations for selecting the appropriate steel frame formwork system for tall structures include factors such as the height and complexity of the structure, the required level of precision and finish, the construction timeline, load-bearing capacity, safety features, ease of assembly and disassembly, and cost-effectiveness. It is important to choose a formwork system that can withstand the vertical loads of the structure and provide stability during the construction process. Additionally, the system should be able to accommodate any architectural or structural requirements, while also being flexible enough to adapt to changes in design or construction methods.

- Q: Can steel frame formwork be used for both horizontal and vertical reinforcement?

- No, steel frame formwork cannot be used for both horizontal and vertical reinforcement. Steel frame formwork is primarily used for vertical reinforcement, such as columns and walls, as it provides strong support and stability during the pouring and curing process of concrete. However, for horizontal reinforcement, such as beams and slabs, other formwork systems like timber or aluminum are commonly used. These formwork systems offer greater flexibility and ease of installation for horizontal reinforcement, which typically requires more intricate designs and arrangements.

- Q: Can steel frame formwork be used in projects with limited availability of skilled labor?

- Yes, steel frame formwork can be used in projects with limited availability of skilled labor. Steel frame formwork is designed to be easy to assemble and dismantle, making it suitable for projects where skilled labor is limited. It requires minimal training and experience to install, reducing the reliance on highly skilled workers. Additionally, the durability and strength of steel frame formwork can handle the demands of construction projects, ensuring the safety and stability of the structures being built.

- Q: How does steel frame formwork handle different types of architectural designs?

- Steel frame formwork possesses remarkable versatility as a construction tool, effortlessly accommodating a wide array of architectural designs. The strength and flexibility of steel make it an ideal material for supporting and shaping intricate structures, allowing architects to transform their creative visions into tangible reality. One manner in which steel frame formwork adapts to diverse architectural designs is through its inherent adaptability. The steel frames can be effortlessly adjusted and reconfigured to suit varying shapes and sizes, facilitating the creation of distinctive and elaborate structures. Whether it entails curved walls, irregular shapes, or sloping surfaces, steel frame formwork can be tailor-made to meet the precise requirements of any design. Furthermore, steel frame formwork boasts exceptional load-bearing capacity, rendering it perfect for constructing expansive and towering structures. This strength empowers architects to explore innovative designs that necessitate substantial structural support. From towering skyscrapers to expansive bridges, steel frame formwork can readily accommodate the demands of diverse architectural designs while ensuring the safety and stability of the final construction. Moreover, steel frame formwork guarantees precision and accuracy throughout the construction process. The frames can be fabricated in a highly controlled environment, ensuring consistent quality and precise measurements. This precision plays a pivotal role in achieving the desired architectural design, as any discrepancies can significantly impact the overall aesthetics and functionality of the structure. In terms of durability, steel is renowned for its robustness and resilience against various environmental factors. Steel frame formwork can withstand harsh weather conditions, corrosion, and regular wear and tear, effectively ensuring the longevity of the structure. This durability renders it a dependable choice for architectural designs that prioritize both aesthetic appeal and long-term functionality. To conclude, steel frame formwork emerges as a versatile and dependable construction tool capable of accommodating a diverse range of architectural designs. Its adaptability, strength, precision, and durability empower architects to push the boundaries of creativity and construct unique and intricate structures. Whether it involves a contemporary skyscraper, a curvilinear building, or a traditional structure, steel frame formwork offers the necessary support and flexibility to transform architectural visions into tangible reality.

- Q: What are the different types of accessories that can be used with steel frame formwork?

- There are several types of accessories that can be used with steel frame formwork to enhance its functionality and efficiency. Some of these accessories include: 1. Formwork clamps: These clamps are used to secure the steel frames together, ensuring stability and preventing any movement during the concrete pouring process. 2. Adjustable formwork props: These props are used to support the formwork system, providing additional strength and stability. They can be adjusted to different heights, making them suitable for various construction projects. 3. Formwork connectors: These connectors are used to connect the steel frames together, providing a seamless and secure joint. They are typically made of high-strength materials to withstand the weight and pressure of the concrete. 4. Formwork ties: These ties are used to hold the formwork panels in place, preventing any movement or displacement during the concrete pouring process. They play a crucial role in maintaining the shape and integrity of the concrete structure. 5. Formwork brackets: These brackets are used to support the formwork system on walls or columns. They provide additional support and stability, allowing the formwork to withstand the pressure exerted by the concrete. 6. Formwork release agents: These agents are applied to the formwork panels to prevent the concrete from sticking to the steel frames. They create a smooth and clean surface, making it easier to remove the formwork once the concrete has cured. 7. Formwork corner solutions: These solutions are used to create smooth and accurate corners in the concrete structure. They ensure that the corners are strong and have a consistent shape, enhancing the overall quality and aesthetics of the finished product. 8. Formwork accessories for special applications: Depending on the specific requirements of the construction project, there are various specialized accessories available. These include formwork for curved structures, formwork for beams and slabs, formwork for stairs, and formwork for tunnels. Overall, these accessories significantly contribute to the efficiency and effectiveness of steel frame formwork systems. They enhance the stability, strength, and accuracy of the formwork, resulting in high-quality concrete structures.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for projects with limited construction budgets?

- When selecting a steel frame formwork system for projects with limited construction budgets, there are several key considerations to keep in mind. Firstly, it is important to evaluate the cost-effectiveness of the system. This includes assessing the initial cost of the formwork, as well as any additional expenses such as transportation, installation, and maintenance. Secondly, the durability and lifespan of the system should be considered to ensure it can withstand the demands of the project without requiring frequent repairs or replacements. Additionally, the versatility and adaptability of the formwork system should be taken into account, as it should be able to accommodate various types of structures and design requirements. Lastly, the availability and accessibility of the system should be considered, as it should be easily procurable within the limited budget and readily available for use. By considering these factors, one can select an appropriate steel frame formwork system that meets both the budgetary constraints and construction needs of the project.

- Q: Can steel frame formwork be used in projects with limited space for storage and staging?

- Yes, steel frame formwork can be used in projects with limited space for storage and staging. Steel frame formwork is known for its compact design and lightweight construction, making it suitable for projects with limited storage space. Additionally, steel frame formwork can be easily stacked and stored, maximizing the available space without compromising on efficiency and productivity.

- Q: Can steel frame formwork be used for healthcare facilities?

- Yes, steel frame formwork can be used for healthcare facilities. Steel frame formwork is a versatile and durable construction method that provides a high level of strength and stability, making it suitable for various types of buildings, including healthcare facilities. Healthcare facilities require robust and long-lasting structures to support the heavy equipment and machinery used in the medical field. Steel frame formwork offers the necessary strength to withstand the weight and stress associated with healthcare equipment. Furthermore, steel frame formwork allows for flexible design options, making it easier to accommodate the specific layout and requirements of healthcare facilities. The modular nature of steel frame formwork allows for easy customization, ensuring that the construction can adapt to the unique needs of healthcare facilities, such as operating rooms, patient rooms, laboratories, and other specialized areas. In addition to its strength and flexibility, steel frame formwork also provides excellent fire resistance, which is crucial for healthcare facilities. Steel has a high melting point, and when properly fireproofed, it can effectively withstand and contain fires, minimizing the risk of spreading and ensuring the safety of patients and staff. Overall, steel frame formwork is a suitable choice for healthcare facilities due to its strength, flexibility, and fire-resistant properties. By using this construction method, healthcare facilities can be built to withstand the demanding requirements of the medical field and provide a safe and durable environment for patients and healthcare professionals.

- Q: Beam column section dimensions of multi story steel frame structures

- When the column is determined, the grillage naturally according to the column grid layout. The main beam of the frame should be arranged on the frame column according to the frame direction.Generally need to be installed in the main beam according to the requirements of the floor beam, the spacing can be 3 ~ 4m.

Send your message to us

Light Steel Frame Formwork for Lower Builidng Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 90000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches