Light Duty Whole Steel Formwork for Low Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

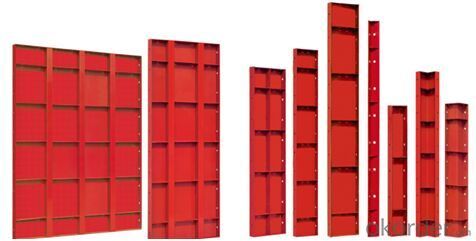

1. Structure of Light Duty Whole Steel Formwork

55 series whole steel formwork is one of the light duty steel formwork. Because of its light weight and high capacity, it is quite popular in the construction market. The thickness of 55 series steel panel is normally 2.75mm and works with different sizes.

2. Main Features of Light Duty Whole Steel Formwork

-Clean and tidy steel panel

-Light weight

-Reduced and Competitive cost

-Solid Steel panel

-Easy to dismantle

-Repeated use of 20 times

3. Light Duty Whole Steel Formwork images

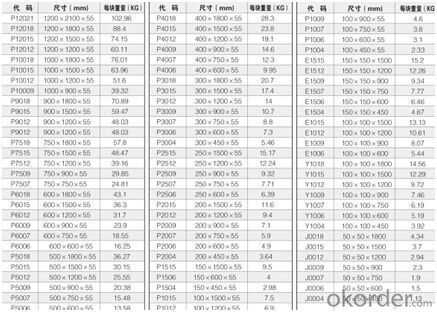

4. Light Duty Whole Steel Formwork Specifications

5. FAQ of Light Whole Steel Formwork

1) What can we do for you?

.We can ensure the quality of the Heavy Duty Whole Steel Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the different types of steel formwork systems available?

- There are several different types of steel formwork systems available, including traditional steel formwork, modular steel formwork, and tunnel formwork. Traditional steel formwork consists of steel panels and supports that are assembled on-site to create the desired formwork structure. Modular steel formwork, on the other hand, is pre-assembled in a factory and can be easily transported and installed. Lastly, tunnel formwork is a specialized type of steel formwork used for constructing tunnels, where the formwork is moved forward as the tunnel progresses.

- Q: Can steel formwork be used for architectural concrete columns?

- Architectural concrete columns can indeed utilize steel formwork. Renowned for its robustness and endurance, steel formwork is an appropriate selection when it comes to erecting concrete columns. With its inflexible structure, it successfully withstands the pressure exerted by the liquid concrete throughout the pouring and hardening processes. Furthermore, steel formwork enables architects to fashion intricate designs and textures on the surface of the concrete columns, thanks to its capacity for precise shaping and detailing. Moreover, steel formwork can be reused numerous times, making it a cost-effective alternative for projects necessitating multiple concrete columns. Nevertheless, it is crucial to ensure that the steel formwork is adequately coated or treated to prevent corrosion and guarantee its longevity.

- Q: What are the challenges of using steel formwork?

- Using steel formwork in construction projects presents a number of challenges. Firstly, the cost of steel formwork is considerably higher compared to alternative options like timber or aluminum. This initial expense can discourage contractors, especially those working with limited budgets on smaller projects. Secondly, the weight of steel formwork is greater than that of other formwork materials, making it more challenging to handle and transport on the construction site. This can result in increased labor costs and slower progress. A further challenge is the inflexibility of steel formwork. Unlike timber formwork, which can be easily cut and shaped to suit specific project requirements, steel formwork is rigid and less adaptable. This can pose difficulties when working on complex or irregular structures. Moreover, the installation and dismantling of steel formwork require skilled labor and expertise. Inexperienced workers may struggle with the process, leading to potential safety risks and inefficiencies. Lastly, regular maintenance is essential to prevent rust and ensure the longevity of steel formwork. Exposure to weather conditions and concrete over time can cause corrosion, compromising the structural integrity. This maintenance work adds both time and cost to the construction project. Despite these challenges, steel formwork still offers advantages such as strength, durability, and reusability. It provides a smooth surface finish for concrete and can withstand high pressure loads. Ultimately, the decision to use steel formwork depends on the specific requirements, budget, and expertise available for the construction project.

- Q: Can steel formwork be used for projects with limited formwork budget?

- Yes, steel formwork can be used for projects with limited formwork budget. Steel formwork is durable, reusable, and has a longer lifespan compared to other types of formwork. It requires less maintenance and can be used for multiple projects, making it a cost-effective option in the long run. Additionally, steel formwork provides better quality finishes and allows for faster construction, reducing labor costs and overall project duration.

- Q: Can steel formwork be used in seismic-prone areas?

- Yes, steel formwork can be used in seismic-prone areas. Steel formwork is known for its high strength and durability, making it suitable for use in areas with high seismic activity. It provides excellent resistance against the lateral forces generated during an earthquake, ensuring the structural integrity of the formwork system. Additionally, steel formwork offers flexibility in design and can be easily adjusted or modified to accommodate the specific requirements of seismic-prone areas. It is important, however, to ensure proper engineering and design considerations are applied when using steel formwork in these areas to ensure it meets the necessary safety standards and regulations.

- Q: What are the different steel grades used in steel formwork?

- There are various steel grades used in steel formwork, including mild steel, high-strength low-alloy (HSLA) steel, and stainless steel. These grades are selected based on the specific requirements of the construction project, such as load-bearing capacity, durability, and resistance to corrosion.

- Q: Can steel formwork be used for precast concrete facades?

- Indeed, precast concrete facades can utilize steel formwork. The utilization of steel formwork entails the establishment of a robust and long-lasting framework for the pouring and molding of the precast concrete panels that constitute the facade. This method presents numerous advantages, encompassing remarkable strength, stability, and the capacity to fashion intricate designs and intricate elements. Moreover, steel formwork possesses the added benefits of effortless removal and reusability, rendering it an economically viable solution for the production of precast concrete facades. Nevertheless, it is imperative to ensure that the steel formwork is meticulously designed and fabricated to satisfy the distinct requirements of the project and the aesthetic preferences associated with the facade.

- Q: How does steel formwork handle construction joints?

- Steel formwork is a versatile and durable option for handling construction joints. It is specifically designed to handle the demands of construction joints and ensure a seamless and efficient construction process. Firstly, steel formwork is known for its strength and stability, which allows it to withstand the pressure and weight exerted on construction joints. This ensures that the formwork remains intact and in place, even when concrete is poured and compacted at the joints. Additionally, steel formwork is highly flexible and can be easily adjusted to accommodate various shapes and sizes of construction joints. This allows for precise and accurate placement of the formwork, ensuring that the joints are properly formed and aligned. Moreover, steel formwork is reusable, which makes it a cost-effective option for handling construction joints. Once the concrete has cured and the formwork is removed, it can be cleaned, repaired if necessary, and used again for subsequent construction projects. This reduces the need for additional formwork materials and minimizes waste. Furthermore, steel formwork provides a smooth and even surface finish, which is crucial for construction joints. It helps to prevent any leakage or seepage of concrete at the joints, ensuring that the structure remains watertight and structurally sound. In conclusion, steel formwork is an excellent choice for handling construction joints. Its strength, flexibility, reusability, and ability to provide a smooth surface finish make it a reliable and efficient solution for construction projects of all sizes and complexities.

- Q: What is the weight of steel formwork panels?

- The weight of steel formwork panels can vary depending on their size and thickness. On average, a standard steel formwork panel might weigh between 50 to 70 kilograms (110 to 155 pounds).

- Q: Can steel formwork be used in areas with limited construction equipment access?

- Yes, steel formwork can be used in areas with limited construction equipment access. Steel formwork is known for its durability and strength, making it suitable for use in remote or difficult-to-access areas. Unlike other types of formwork, steel formwork does not require extensive machinery or equipment for installation. It can be easily transported and assembled manually, reducing the reliance on heavy machinery. Additionally, steel formwork is reusable, which means it can be disassembled and moved to different locations if necessary. This versatility makes steel formwork a practical choice for construction projects in areas with limited equipment access, ensuring efficient and cost-effective construction processes.

Send your message to us

Light Duty Whole Steel Formwork for Low Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords