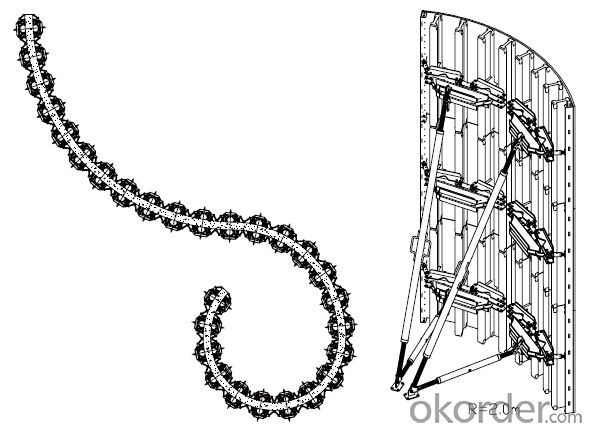

Adjustable Arced Steel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Adjustable Arced Formwork

For pouring arced wall or column with radius more than 1m.

Characteristics:

◆ Adjustable radius, flexible application.

◆ Easy operating, economical efficiency.

- Q: Is steel formwork suitable for projects with high formwork complexity?

- Steel formwork is a great option for projects that have intricate formwork needs. It can be customized and shaped to meet the requirements of complex projects, making it ideal for structures that are curved or non-standard. Furthermore, steel formwork is strong and durable, able to withstand the pressures and loads of construction. This makes it suitable for projects that require heavy reinforcement or large concrete pours. Additionally, steel formwork provides smooth and uniform surfaces, resulting in high-quality finishes. While it may require a higher initial investment, its long lifespan and reusability make it a cost-effective choice. Overall, steel formwork is a flexible, strong, and durable option that can provide high-quality finishes for complex projects.

- Q: Can steel formwork be used for architectural concrete walls with complex geometries?

- Yes, steel formwork can be used for architectural concrete walls with complex geometries. Steel formwork offers excellent strength and durability, making it suitable for creating intricate shapes and designs in concrete walls. It provides the necessary support and stability during the casting process, ensuring that the concrete retains its desired form and shape. Additionally, steel formwork is versatile and can be easily customized to meet the specific requirements of complex architectural designs.

- Q: How does steel formwork affect the overall thermal performance of the structure?

- Steel formwork does not significantly affect the overall thermal performance of a structure as steel is a good conductor of heat. However, it can indirectly impact thermal performance by providing a solid structure that helps in maintaining insulation materials in place, thereby improving the overall energy efficiency of the building.

- Q: What are the common design considerations for steel formwork in bridge construction?

- Some common design considerations for steel formwork in bridge construction include the structural integrity and stability of the formwork system, the ability to withstand the weight and pressure of the concrete during pouring and curing, the ease of assembly and disassembly, the ability to accommodate variations in bridge geometry and dimensions, and the durability of the formwork system to withstand harsh environmental conditions.

- Q: Can steel formwork be used for infrastructure construction projects?

- Indeed, infrastructure construction projects can make effective use of steel formwork. This option, known for its versatility and durability, proves ideal for a range of infrastructure types including bridges, tunnels, dams, and buildings. Given its strength and rigidity, it can withstand the heavy loads and high pressures commonly associated with such projects. Moreover, its easy dismantling and reusability factor into its cost-effectiveness and sustainability. As an added advantage, steel formwork offers flexibility for customization, enabling precise and accurate construction tailored to specific project requirements. Ultimately, steel formwork stands as a dependable and efficient solution for infrastructure construction projects.

- Q: How does steel formwork compare to other formwork materials in terms of durability?

- Steel formwork is known for its exceptional durability compared to other formwork materials. Its strength and resilience make it capable of withstanding heavy loads and harsh weather conditions, ensuring long-term stability and reliability. Unlike wooden or plastic alternatives, steel formwork does not warp, rot, or deteriorate over time, making it a highly preferred choice for construction projects that require long-lasting and robust formwork solutions.

- Q: How does steel formwork affect the overall aesthetics of a concrete structure?

- Steel formwork can greatly enhance the overall aesthetics of a concrete structure. Its smooth and precise finish allows for clean lines and sharp edges, resulting in a visually appealing appearance. The use of steel formwork also provides the flexibility to create intricate designs and patterns, adding unique features and architectural elements to the structure. Additionally, steel formwork ensures consistent and uniform concrete surfaces, minimizing imperfections and improving the overall quality of the finished product.

- Q: Can steel formwork be used for foundation walls?

- Indeed, steel formwork proves to be a suitable choice for foundation walls. With its durability and strength, this material offers exceptional support for concrete during construction. It is versatile enough to be applied both horizontally and vertically, including for foundation walls. The benefits of steel formwork are numerous, encompassing a high load-bearing capacity, reusability, and effortless installation and removal. This formwork enables precise shaping of foundation walls, guaranteeing a seamless and consistent finish. Moreover, steel formwork's resistance to moisture and ability to endure harsh weather conditions make it a fitting option for foundation walls in diverse environments.

- Q: What are the different components of steel formwork?

- Steel formwork is a type of temporary structure that is used in construction projects to provide support and shape to concrete during the curing process. It consists of several components that work together to create a rigid and durable formwork system. The main components of steel formwork include: 1. Panels: These are the primary components of the formwork system and are usually made of steel or steel-reinforced plywood. They are available in different sizes and shapes and can be easily interconnected to create the desired formwork configuration. 2. Soldiers: These are vertical members that provide support to the formwork panels. They are typically made of steel and are adjustable in height, allowing for flexibility in formwork design. Soldiers are connected to the panels using connecting clamps or pins. 3. Waler Beams: These are horizontal members that help distribute the load evenly across the formwork system. Waler beams are connected to the soldiers using clamps or brackets and are usually made of steel or aluminum. 4. Tie Rods: These are used to hold the formwork panels and soldiers together. They are threaded rods that pass through the panels and are secured with nuts and washers on each side. Tie rods help in maintaining the required spacing between the panels and provide additional strength to the formwork system. 5. Formwork Accessories: These include various components such as clamps, brackets, wedges, and pins that are used to connect and secure the formwork components. They help in maintaining the stability and alignment of the formwork system during concrete pouring and curing. 6. Formwork Joints: These are specially designed connectors that allow for easy assembly and disassembly of the formwork system. They ensure proper alignment and tightness of the formwork components, preventing leakage of concrete and maintaining the desired shape. 7. Formwork Supports: These are used to provide additional support to the formwork system, especially for larger and complex structures. Formwork supports can be in the form of props, scaffolding, or specialized shoring systems, depending on the specific requirements of the project. Overall, these components work together to create a strong and stable formwork system that can withstand the pressure and weight of the concrete during the construction process. Steel formwork is preferred for its durability, reusability, and ease of assembly and disassembly, making it a popular choice in modern construction projects.

- Q: Can steel formwork be used for residential tower construction projects?

- Yes, steel formwork can be used for residential tower construction projects. Steel formwork is highly durable, versatile, and has a high load-bearing capacity, making it suitable for constructing tall structures like residential towers. Additionally, steel formwork provides excellent dimensional accuracy and can be easily customized to meet the specific design requirements of residential towers.

Send your message to us

Adjustable Arced Steel formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords