Steel-frame Formwork System Link Part

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel-frame Formwork SF-140

Characteristics:

◆ Few parts for fast forming.

◆ Max. Concrete pressure: 80KN/m2.

◆ Hot-dip galvanized steel frame.

◆ The thickness of plywood is 18mm & the panel is 14cm.

◆ Compatibility with Hunnebeck Manto system due to similar edge profile.

System Details & Application:

◆ Neat joint and fast assembling with aligning panel clamp.

◆ Flexible panel arrangement and height extension.

◆ The selection of panels.

◆ Kinds of panel connectors.

◆ Corner clamp application.

◆ Length adjustment application.

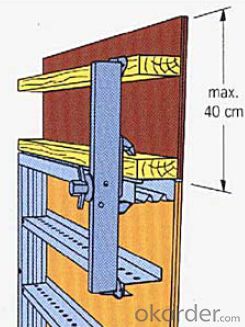

◆ Height adjustment & aligning strut.

◆ Walkway bracket & platform.

- Q:Can steel formwork be custom-made?

- Yes, steel formwork can be custom-made. Steel is a versatile material that can be easily shaped and welded to create formwork that meets specific project requirements. Custom-made steel formwork is often used in construction projects where standard formwork systems may not be suitable due to unique design elements or complex geometries. By customizing the steel formwork, construction companies can ensure that it fits perfectly, resulting in efficient and accurate concrete pouring, reducing waste and saving time and costs. Custom-made steel formwork also offers the advantage of durability and reusability, providing long-term benefits for multiple construction projects.

- Q:What are the different locking mechanisms used in steel formwork?

- To ensure stability and integrity in concrete construction projects, various locking mechanisms are employed in steel formwork. These mechanisms are designed to securely fasten the formwork panels together, preventing any shifting or movement that could compromise the accuracy and quality of the final concrete structure. One widely used locking mechanism is the wedge clamp system. This system utilizes steel wedges, which are inserted between the formwork panels and tightened with a hammer or mallet. The wedges establish a robust connection between the panels, firmly anchoring them in place. Another popular locking mechanism is the pin and wedge system. This system involves the insertion of steel pins through holes in the formwork panels. Subsequently, steel wedges are driven into these holes, securing the pins firmly. This creates a stable and secure connection between the panels. Some steel formwork systems also employ a hook and loop mechanism. This entails the attachment of metal hooks to one panel and metal loops to the neighboring panel. The hooks and loops interlock, providing a strong connection between the panels. This mechanism is often favored for its convenience and efficiency, making it a popular choice for specific construction projects. Moreover, certain steel formwork systems combine different locking mechanisms. For instance, a system may incorporate both wedge clamps and pin and wedge systems to enhance stability and strength. Ultimately, the various locking mechanisms employed in steel formwork serve the purpose of ensuring the secure connection of formwork panels throughout the concrete pouring process. Each mechanism offers its own advantages and may be more suitable for specific project requirements.

- Q:How does steel formwork prevent concrete bleeding?

- Steel formwork is a type of temporary structure that is used in construction to hold and shape the concrete until it sets and hardens. One of the advantages of using steel formwork is that it can help prevent concrete bleeding, which is the process of water separating from the mixture and rising to the surface. Steel formwork is typically designed with tight joints and smooth surfaces, which helps to create a watertight seal around the concrete. This prevents water from seeping out of the mixture and rising to the surface, reducing the occurrence of concrete bleeding. Additionally, the rigid nature of steel formwork prevents the concrete from settling or shifting during the pouring process, further minimizing the potential for bleeding. Furthermore, steel formwork offers better stability and durability compared to other types of formwork materials. Its rigid structure ensures that the formwork remains intact and maintains the desired shape during the concrete pouring process, preventing any movement that could lead to bleeding. In conclusion, steel formwork prevents concrete bleeding by providing a tight seal, stability, and a smooth surface. These features prevent water from separating from the mixture and rising to the surface, resulting in a higher quality and more visually appealing concrete finish.

- Q:What are the different types of steel formwork corner solutions?

- There are several different types of steel formwork corner solutions that are commonly used in construction projects. 1. External corner brackets: These are L-shaped brackets that are attached to the external corners of the formwork. They provide additional support and stability to the formwork system, ensuring that it remains in place during the pouring and curing of concrete. 2. Internal corner brackets: Similar to external corner brackets, internal corner brackets are used to support and reinforce the formwork at internal corners. They help to maintain the structural integrity of the formwork system, preventing any bulging or deformation that could occur during the concrete pouring process. 3. Adjustable corner connectors: These connectors are designed to allow for flexibility in adjusting the angles of the formwork corners. They are particularly useful in situations where the angles of the corners are not standard or require customization. Adjustable corner connectors can be easily adjusted to accommodate different angles, ensuring a precise fit and alignment. 4. Corner chamfers: Corner chamfers are used to create chamfered or beveled edges at the corners of the concrete structure. They not only provide a decorative finish to the corners but also help to prevent any sharp edges, making the structure safer and more aesthetically pleasing. 5. Corner formwork systems: These systems are specifically designed to create formwork for corner sections. They consist of pre-fabricated steel panels that are connected together to form a corner shape. These systems are easy to install and remove, saving time and effort during the construction process. Overall, the choice of steel formwork corner solution depends on the specific requirements of the construction project. Factors such as the angle of the corners, the load-bearing capacity needed, and the desired finish will determine which type of solution is most suitable.

- Q:How does steel formwork ensure accurate concrete dimensions and alignment?

- Steel formwork ensures accurate concrete dimensions and alignment by providing a rigid and stable structure that holds the concrete in place during the pouring and curing process. The steel formwork is designed and fabricated to precise specifications, allowing for precise shaping and positioning of the concrete. The use of steel formwork also reduces the risk of deformation or shifting during the concrete setting, ensuring that the final dimensions and alignment of the concrete structure are maintained.

- Q:How does steel formwork contribute to the overall stability of a structure?

- Steel formwork contributes to the overall stability of a structure by providing a robust and rigid framework for concrete placement. Its strength and durability prevent deformation or displacement during the pouring and curing process, ensuring the concrete sets in the desired shape and position. This stability allows for the proper alignment and distribution of loads, enhancing the structural integrity of the building and reducing the risk of any potential structural failures.

- Q:Can steel formwork be used for both straight and curved concrete elements?

- Yes, steel formwork can be used for both straight and curved concrete elements. Steel formwork is highly versatile and can be easily adjusted and shaped to accommodate different design requirements. It offers excellent strength and durability, making it suitable for constructing both straight and curved concrete elements. The flexibility of steel formwork allows for the creation of complex and intricate shapes, making it ideal for projects that require curved elements such as architectural features, curved walls, or circular structures. Additionally, steel formwork provides a smooth and uniform surface finish, ensuring high-quality concrete results for both straight and curved elements.

- Q:How does steel formwork affect the overall weight of the structure?

- Steel formwork can significantly affect the overall weight of a structure as it is typically heavier than other types of formwork materials such as wood or aluminum. The weight of steel formwork can increase the dead load on the structure, potentially requiring additional structural support and impacting the design and construction process. However, steel formwork offers advantages in terms of durability, strength, and reusability, making it a preferred choice in certain construction projects despite its impact on the overall weight.

- Q:How does steel formwork help in achieving a high-quality finish?

- Steel formwork helps in achieving a high-quality finish due to its ability to provide a strong and rigid structure for concrete placement. Its smooth and non-absorbent surface prevents the formation of air bubbles, resulting in a smooth and even finish. Additionally, steel formwork allows for precise and accurate shaping and alignment, ensuring the desired dimensions and contours of the final concrete product.

- Q:Can steel formwork be used for foundation construction?

- Yes, steel formwork can be used for foundation construction. Steel formwork is a versatile and durable option for constructing foundations. It provides a strong and stable support system for pouring concrete and creating the desired shape and structure of the foundation. Steel formwork offers several advantages such as ease of assembly and disassembly, reusability, and the ability to withstand heavy loads and pressure. Additionally, steel formwork is highly resistant to moisture and can be easily cleaned, making it suitable for use in foundation construction projects. Overall, steel formwork is a reliable and efficient choice for constructing foundations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel-frame Formwork System Link Part

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords