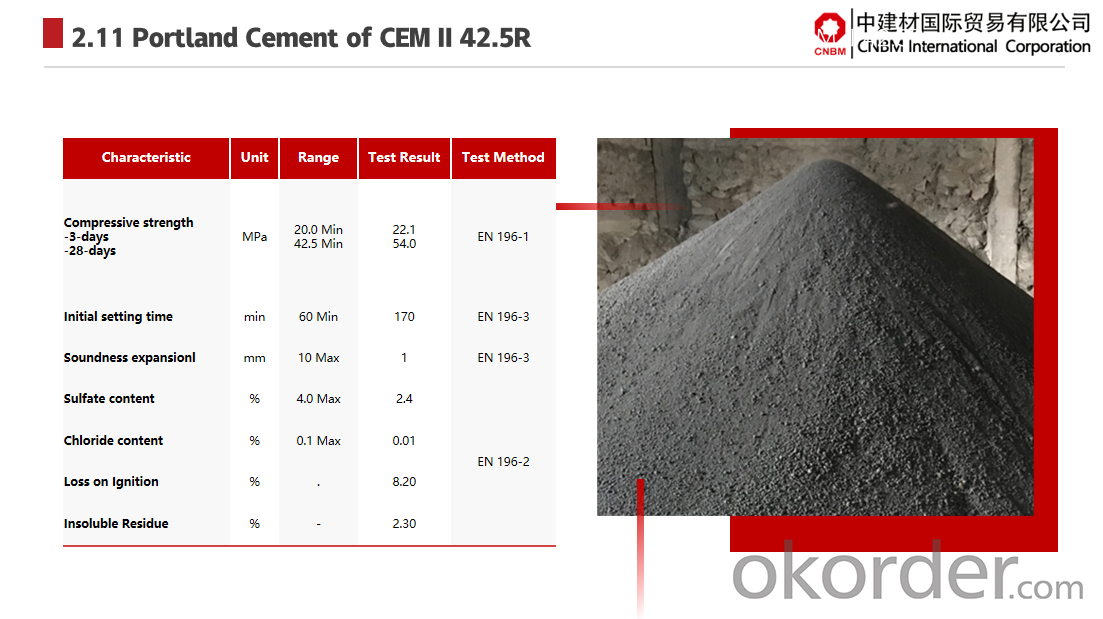

Highest quality for Portland cement of CEM II 42.5R

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PORTLAND CEMENT

Portland cement is the most common type of cement in general use around the world, used as a basic ingredient of concrete, mortar, stucco, and most non-specialty grout.

It is a fine powder produced by heating materials in a kiln to form what is called clinker, grinding the clinker, and adding small amounts of other materials.

Several types of Portland cement are available with the most common being called ordinary Portland cement (OPC) which is grey in color, but a white Portland cement is also available.

Application

CNBM Cement can be used for all types of architectural or structural concrete construction. Such application as pre-cast panels and systems, cast-in-place, masonry units, tilt-up panel systems, roofing tiles, terrazzo floors, highway median barriers, tile grout, swimming pools, stucco, culture stone,colored masonry products, cement paints and coatings, and ornamental precast concrete items.

CNBM INTERNATIONAL CORPORATION (short for the Company) is a subsidiary of China National Building Material Group Co., Ltd. (short of CNBM Group). China National Building Material Group is a state owned enterprise under directly management of the State-owned Assets Supervision and Administration Commission of the State Council, and ranked 187 in the world's top 500 in 2019. China National Building Materials Group is the world's largest comprehensive building materials industry group, the world's leading new material developer and comprehensive service provider, and has the strongest scientific research strength in the field of building materials and non-metal new materials. CNBM INTERNATIONAL CORPORATION is a brand-new platform built by China National Building Materials Group that focuses on non-metallic materials trading.

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:TT and LC are both Okay.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: how to calculate quantity of cement in concrete?

- The Portland Cement Association's Design and Control of Concrete Mixtures is a definitive book on the subject. It can be purchased at the first link below. The second link is to a web page at Union College, which contains a tutorial on concrete mix design.

- Q: i would like to know how the cement grade be checked? kindly let me know what other test can be done to know the quality of cement?

- Don't usually check the portland cement, usually you test the concrete mix to assure it gives you the strength you desire. This is usually done with actual breaks of cylinders made from the mix you want to use, done before the mix design is approved. Then, additional cylinders are cast while placing the concrete and tested at intervals over a 28-30 day period to make sure the concrete strength meets your requirements. The exact number of cylinders is usually decided by the owner or engineer, based on the amount of concrete poured at one time. The minimum number of cylinders is usually 3, one to break at 3-7 days, one to break at 28-30 days, and one spare.

- Q: does anyone have any experience in that? does it reduce the noise a lot or just a bit? and about the ceiling... my neighbors throw and drag things on the floor (they're mental cases, fruitcakes). i can't afford to move right now because the house is bought so i'd have to sell and buy another house. can't do that right now. and it always costs money.to what extent will the cement on the ceiling reduce the noise?what kind of windows are the best?thank you all...

- Sound proofing has to do with mass, density and a few other factors. Robin is both right and wrong. Glass is extremely dense and heavy. If you replace glass with light weight plastic in the same configuration it won't protect anywhere near as much. The more panes of glass you have with distance in between them, the more sound proof it gets. Restaurants often put two windows in a row for silencing noise. For the wall add more drywall. Double the mass of the wall or cieling and it will absorb another 5 to 10 decibels of protection. If you can afford 1 to 2 dollars a square foot, then use a viscoelastic damped product such as Quietrock drywall, Supress drywall, or soundbreak drywall or buy viscoelastic damping glues such as QuietGlue, Green Glue, or Decibel Drop. Viscoelastic polymers convert vibration into heat. They are used in electronics as an alternative to protect against vibration, in building material to provide sound damping, sometimes in earthquake protection to reduce the vibrations that the building has to put up with, and in high end cars to reduce frame vibration. I just named some common products for building materials. Specialty drywall warehouses will be familiar with some of these products. Lumber yards and common stores won't have a clue.

- Q: I never used to be allergic to anything and then a few years ago developed an allergy to shell fish. Yesterday I was working with rubber cement for the first time and I had a major allergic reaction similar to the ones I would have after eating shrimp. Is there anything in rubber cement that would relate to shellfish? There is nothing printed on the label but it does warn of allergic reactions if you are allergic to latex gloves. Not sure if I am or not but maybe.....given this experience.

- Rubber cement is an adhesive made from elastic polymers (typically latex) mixed in a solvent such as acetone, hexane, heptane or benzene to keep them fluid enough to be used. This makes it part of the class of drying adhesives: as the solvents quickly evaporate, the rubber portion remains behind, forming a strong yet flexible bond. Often a small percentage of alcohol is added to the mix.

- Q: There just little pieces of cement no bigger then a nickel and it made the glass look all foggy and nasty and I was wondering if there like a chemical compound or something I can use to break it down. If there is, is there anyway you can make it at home using household products? Please and Thank You

- How To Break Cement

- Q: I was watching amastad (sp) and pirates of carribean. They mentioned tying cement blocks to feet and throwing them over board. What happens to the human body? Do they drown first or are they crushed? I love learning new things. Plus I'm bored. So this thought came to mind. Anyone know what possibly happened to people way back when?

- They tie it to their feet and push them off and they drown and sink

- Q: What are the differences between 43 grade and 53 grade cement?

- The strngth of cement such as 53 or 43 grade does not hold any consideration during calculation of Mix Design. It has no parameter at all. More over in India Hybrid no cement has been designated in grade apart from 33 grade. Over and above use of OPC cement all over the world is decreasing considerably. Hence by producing higher grade of cement the Cement Companies simply befooled us.

- Q: Do cement finishers often work long hours?

- In the Phx area, they work early mornings........but not usually more than 8-9 hours a day

- Q: How much cement is left in the U.S.?

- Cement is not a raw material, it's something manufactured and there are huge amounts of the raw materials (clay, limestone) that go into it.

- Q: We are creating cement test samples in construction materials class and our group is to use a .55 water/cement ratio. Our test cylinder is 4quot; diameter by 8quot; height. I know that this is 0.058 ft?. I am having trouble trying to figure out a formula that i can figure out how much water/cement/aggregate that i should put in this cylinder in order to make 0.058 ft?.

- First you need to determine the specific density of the cement usually 3100kg/m3. The aggregate and sand will be about 2600kg/m3. Next determine the ratio of cement to fine aggregate (sand) to coarse aggregate. A fairly low strength concrete would have a ratio by weight of 1:2:4. The density of the finished concrete will be about 2400kg/m3. So start with 100kg of OPC (Ordinary Portland Cement) then fine aggregate is 200kg and coarse aggregate is 400kg. The water is 55kg (0.55 w/c ratio). Add up total weight and obtain volume by using overall density of mixture (2600kg/m3). This volume is called the yield. By using the ratio of the quantity that you require against the yield using 100kg of OPC you can calculate the amount of OPC, sand, Aggregate and water that you need.

Send your message to us

Highest quality for Portland cement of CEM II 42.5R

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords