AR Fiberglass/Glass Fiber roving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

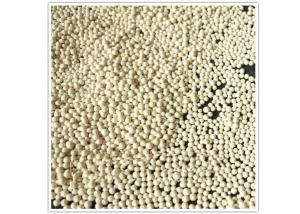

ar fiberglass roving

1.Easy chopped

2.Good integrity and dispersibility

3. alkali resistant

4. excellnt durabilty

alkali resistant continuous roving ar glass fiber roving

1. Ar fiberglass roving

AR glass gun roving is mainly designed for use in the manufacture of GRC composites by the manual spray method. It is designed for optimum processability. It is used in the manufacture of GRC architectural panels and other building elements, civil engineering and infrastructure components.

PRODUCT NAME | AR GLASSFIBER SPRAY ROVING | |||

TEST CRITERION | JC/T 572-2002 | |||

TEST ITEM | METERAGE UNIT | STANDARD | RESULT | CONCLUSION |

ZrO2 CONTENT | % | ≥16.0 | 16.7 | MEASURE UP |

FILAMENT DIA | μM | 13±2 | 13 | MEASURE UP |

STRAND TEX | TEX | 2700±270 | 2720 | MEASURE UP |

BREAKING STRENGTH | N/TEX | ≥0.25 | 0.32 | MEASURE UP |

MOISTURE CONTENT | % | ≤0.2 | 0.11 | MEASURE UP |

COMBUSTIBLE CONTENT | % | 0.8~2.0 | 1.68 | MEASURE UP |

STIFFNESS | MM | ≥120 | 170 | MEASURE UP |

CONCLUSION | IN CONPLIANCE WITH JC/T 572-2002 | |||

2. Pallet Packing

1) Each pallet has 3 or 4 levels ,16rolls /level.

2) The complete pallet is enclosed in polythene and identified with two labels.

Product | Level per pallet | Total number of cheese | Pallet | |||

Length(mm) | Width(mm) | Height(mm) | Net weight(kg) | |||

ARC15-2400L | 3 | 48 | 1130 | 1130 | 1000 | 860 |

3 | 48 | 1130 | 1130 | 1000 | 1000 | |

4 | 64 | 1130 | 1130 | 1300 | 1150 | |

Shipment

For sea transport, a maximum of 20 pallets (on two levels) may be loaded in a 20 foot container, giving a total net weight of approximately 17-20 tonnes.

3. Storage

AR GLASSFIBRE SPRAY ROVING should be stored dry in their original packaging, the best conditions being at a temperature of between 15°C-35°C and at a relative humidity of between 35% - 65%. If the product is stored at low temperature (below 15°C) it is advisable to condition in the workshop for 24 hours before use to prevent condensation.

4. Production flow chart

- Q:I was washing paint brushes in a bucket with water the bucket turned to mostley paint and then the bucket fell on my pation floor which is cement now it wont come off!!!!!!

- High pressure water.

- Q:water pipe burst, put new pipe and cleaned and put on PVC cement, What is recommended time to dry before tyurning on water?

- There are different glues with different drying times,....read the instructions.

- Q:bouncing the ball on the cement first then change to bouncing the ball on the carpet to see which floor the ball bounces the highest is my independent Variable the carpet? Is the dependent Variable the lower bounce on the carpet. Is the controlled variable the quality of the carpet

- Your independent variable is the thing that changes, which is the surface the ball is bounced on (like cement or carpet, but not just one of those) Your dependent variable is the variable that is effected by the independent variable, so the height that the ball bounces. Your controlled variable is the thing that does not change, the constant, so that would be your ball. Tips: for a good experiment, you should have more than 2 things in the the independent variable, so you should try other surfaces as well such as wood. Also, to avoid any error, buy multiple of the same ball and use each one on a different surface. That way the cement won't scratch the ball and cause friction between the ball and the carpet, but the balls will have the same bounce so it won't change the height.

- Q:how many bags of cement will i need for a12x12 patio?

- 80lb bags of concrete.

- Q:I'm writing an essay on cement, one of the requirements is to define technology, but i don't just want a definition in the middle of my essay, so i need to make one paragraph relating technology with cement. any advice, pointers, ideas, would be greatly appreciated!

- Well, you see, good cement/technology is strong, and much better and more useful things can be bulit upon it, but weak cement/technology doesn't last long, and nothing good can be built on it.

- Q:How much cement is left in the U.S.?

- Cement is not a raw material, it's something manufactured and there are huge amounts of the raw materials (clay, limestone) that go into it.

- Q:will i get crutches from er if i hit my knee cap on the cement step and went to the er or walk in clinic please explain and what if i just go in hopping in on one leg do you think they would give me crutches. do they show you how to use them please explain i want to use crutches

- They will examine you first, and if you don't need crutches, they won't give them to you. It is horrible that you would want to waste everyone's time in the ER simply because you want crutches. While they ER staff are dealing with you, someone who is actually hurt is having to wait a little longer. Go to a medical supply store any buy some crutches if you want them so bad.

- Q:construction, cement, concrete

- ...do the concrete cube test.....different countries have different standards... ,,generally...the cement acts as the bonding agent for the concrete mixture..and thus the main factor that determines the resistant factor to resist compression...

- Q:What is the use of using oxygen in cement industry?

- The ingrediants for the cement need to be heated to a very high temperature to make Portland cement. Usually methane with air is the heat source, but oxygen replacing some of the air is sometimes needed to reach the optimum temperature. Possibly a superior cement is produced if it has negligible nitrogen, argon and carbon dioxide, so oxygen is used instead of air which contains nitrogen, argon and carbon dioxide as well as oxygen.

- Q:My sister is pouring a sidewalk alongside her house, and wants to have bare foot imprints of her and her two daughters. Its not my thing, but is this safe? I don't think wet cement can hurt you, but is it healthy to go barefootin' in, haha?

- I haven't worked too much with concrete... But! I'm thinking that it wouldn't hurt to put some vaseline on those little feet. I don't think the vaseline will hurt the cement. It might slow the drying process just a bit..... I don't know. You could always cover the cement with some press n' seal or other thin plastic...... the shape of the foot should still be made. I'm curious about this now..... You know, they do have kits sold at the arts crafts store...for kid's to making stepping stones. Maybe you should check one of those out first......

1. Manufacturer Overview |

|

|---|---|

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

AR Fiberglass/Glass Fiber roving

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords