New Ceramic Honeycomb Catalytic Converter

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Large specific surface area.

2.Good thermal conductivity.

3.For automobile,motorcycle.

Detailed Descriptions:

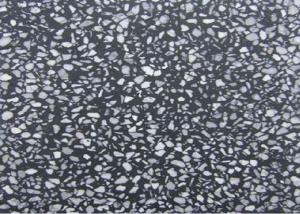

Honeycomb ceramic is a new developed porous industrial ceramic. As heat storage body, it has the properties of corrosion resistances, large specific surface area, small heat resistance, good thermal conductivity and excellant thermal-shock resistance performance, realize quickly exchanging heat and reducing energy, widely used in the industrial field. The honeycomb ceramic as the heat exchange media is the key part for heat storaging HTAC ( High Temperature Air Combustion) technology. It is the best choice for RTO, heat exchanger and other environmental protection and energy saving products.

The honeycomb ceramic used as catalyst carrier (used in vehicle):

Used as catalytic converters of gasoline engines, the honeycomb ceramic catalyst substrates are coated by catalyst. At the same time, we improve the specific surface areas and cut down the heat capacity to increase the catalytic function. When the noxious emissions pass through, HC, CO and NOX will be converted into harmless components.

Main Features:

1. High specific surface area: ensure exhaust gas could contact weigh catalyst enough.

2.Stable water absorption: guarantee catalyst could be firmly and evenly coated on the surface of substrate, so it's no waste to the thick coating.

3. We can provide honeycomb ceramic substrate coated and non-coated with noble metal.

4. We can produce the honeycomb ceramic series with different shapes and sizes according to customers’ requirements.

Technical Data:

Channel density | Shape | Dimensin (mm) |

400cells/square inch2 | Round | Φ150 x100 |

Φ144 x152.4 | ||

Φ118 x152.4 | ||

Φ115.4 x152.4 | ||

Φ106 x100.4 | ||

Φ103x100 | ||

Φ101.6x152.4 | ||

Φ100x100 | ||

Φ93 x152.4 | ||

Φ83 x152.4 | ||

Φ80x100 | ||

Φ76x50 | ||

Φ41x25 | ||

Racetrack shape(ellipse) | Φ169 X 85.7 x115 | |

Φ169 X 80.8x115 | ||

Φ148 X 84x152.4 | ||

Φ144.8 X 81.3 x152.4 | ||

Φ127 X 63.5x152.4 | ||

Φ93 X 61x90 | ||

Φ120 .6X 80 x152.4 | ||

Φ143 X 98x152.4 | ||

Φ147 X 95x152.4 | ||

Φ177.8 X114.3x170 | ||

Special shape | 144x84x75 | |

114x105x115 | ||

120.2x108.2x75 | ||

112.2x92x115 | ||

119.5x99.5x115 | ||

122.3x104.4x80 |

Note:

1. There are 300 cells, 400 cells and 600 cells per square inch.

2. All the data is only for reference, specific sizes and hole shapes are according to customers' requirements.

- Q: Egypt cement price ?

- 420 lee for ton

- Q: my boyfriend wants the jordan black cement 3's from 2011 do u know the price of them and where i can buy them ? thank uuu :)

- Probably the most common occurrence and issue out there is having gum stuck on your shoes. There are time when it comes right off, then there are times when it's a desperate struggle to remove every single sticky bit of it off your shoes. The Air Jordan 3 has had a big year with some much loved, classic colorways returning to NikeStore, as well as a new edition especially for this year. Launching on Black Friday is the next installment the iconic Black/Cement Air Jordan 3 Retro. With big-time innovation and lethal good looks, the Air Jordan 3 was the first shoe designed by Tinker Hatfield and features visible Nike Air and elephant print alongside the introduction of the iconic Jumpman logo. The launch of this shoe was the first time Spike and Mike hooked up and Mars Blackmon started hitting TV screens around the world.

- Q: I need to find the properties and additives of a cement produced by a cement producer on their web page or from a catalog. This needs to come from an on-line source. Any ideas? Thanks!

- Portland Cement Cement Composition. The composition of portland cements is what distinguishes one type of cement from another. ASTM C 150 and AASHTO M 85 present the standard chemical requirements for each type. The phase compositions in portland cement are denoted by ASTM as tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminate (C3A), and tetracalcium aluminoferrite (C4AF). However, it should be noted that these compositions would occur at a phase equilibrium of all components in the mix and do not reflect effects of burn temperatures, quenching, oxygen availability, and other real-world kiln conditions. The actual components are often complex chemical crystalline and amorphous structures, denoted by cement chemists as elite (C3S), belite (C2S), and various forms of aluminates.

- Q: Can a grenade blow through brick/cement wall?

- Most definitely.

- Q: what is sound proof cement made out of?

- Cement isn't really sound proof. If someone said something like I was trapped in a sound proof cement chamber It means that the chamber was sound proof, not the cement it self.

- Q: will loquid elmers or rubber cement work better for glueing papers together

- that depends on whether or not you want to be able to take the papers apart later or not. if you do then i would go with the rubber cement, if not then elmers all the way. another thing to keep in mind is that elmers glue is known to cause the paper to crinkle and in my opinion, that ruins the presentation of the whole project.

- Q: I think we have been already taught how this goes, butIf you mix water and cement, and you record the mass while it's still wet, then if it dries, will you also get the same mass? if not, much percent do you think will be lost?

- The problems with cement is that it's a very Thirsty molecule. Could be all the water remains in the concrete. Concrete doesn't harden because it loses it's water - it hardens because of a chemical change (it's hot). Portland cement can harden under water - and the Romans understood this. Some of their bridges are still in use. Then the idea was lost until the end of the 18th century, I think.

- Q: It is one of those hollow cement/crushed stone stairs outdoors. The top step has a crack and small hole. ( Because of such changes in warm to cold weather this must have happened) There must be a fairly easy , non-expensive way to try and repair this step before it caves in

- I use 3 parts of Portland cement to 2 parts of sand for such a repair. First take and clean out the area of all loose materials and then coat it with a coat of Latex paint. Then mix the Portland and sand dry, then add to about a gallon of the mixture a 1/4 cut of that latex paint, add water to suit giving a consistency of tooth paste. Fill the hole, let it sit for at least 2 hours, then scrape it neatly with a trowel, leveling it. This bond with the latex is about the best around, better that any sort of stuff sold at Lowes or Home Depot. Our local hardware store has Portland cement in 10# bags so you dont have to go out and get a 100# bag. Buy your bagged sand right there too. DO NOT use the premix stuff ( sand and cement) in a bag, simply not enough Portland in that stuff and a sure way to have a failure of this patch.

- Q: include social, environment and economical factors

- social: Not always the most attractive looking material. Some concretes and cements create a gloomy and depressing atmosphere. Environmental: Concrete and cement release green house gases. Concrete/cement footpaths over up natural soils and leave less room for trees to be planted and less natural earth for insects to live in. Economic: Expensive to remove and dump. In some cases, some cement foundations are so deep they are impossible to remove, meaning the land they're on cannot be used for much else, decreasing the land resources in the economy

- Q: 420 kg cement how many cubic feet?

- wet or dry? assuming dry: But there are many unknowns, see below. I'll take a number of 1000 kg/m? and you can change as needed 420 kg / 1000 kg/m? = 0.4 m?, which converts to 14 ft? Cement (finely ground gray or white powder used to bind concrete mixtures) weighs between 830 kg/m? and 1650 kg/m? depending on its handling. The weight of cement that has been pneumatically loaded into a cement silo may be as low as 830 kg/m?, while cement that has been stored for a period of time exposed to vibration may be as heavy as 1650 kg/m?.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000;CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao PORT, Yantai port, Shanghai port |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | Above 50 People |

| Language Spoken: | English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian |

| b) Factory Information | |

| Factory Size: | 1,000-3,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

New Ceramic Honeycomb Catalytic Converter

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords