Vietnam Handmade Cement Tile Language Option French

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meter/Square Meters m²

- Supply Capability:

- 5,000 Square Meter/Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

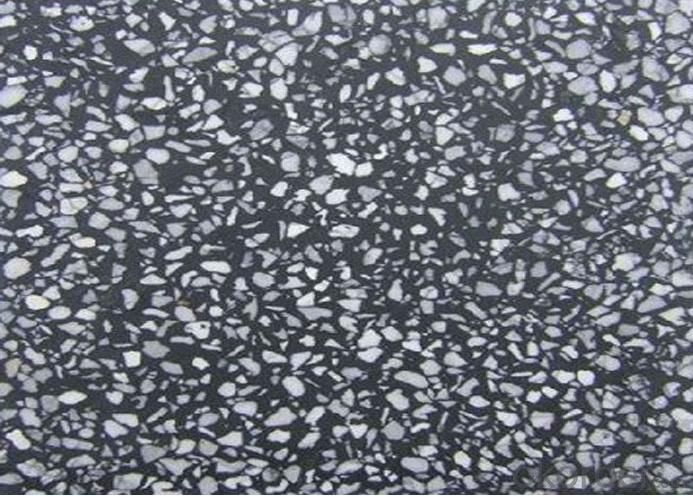

Vietnam Handmade Cement Tile

Water Absorption: <= 7%

Abrasion: +0.45gr/Cm2

Weight: 1200gr +/- 50gr

Elasticity: 1.200N min

This is encaustic cement tile, a produce of HANDMADE process created by Skillful Artisant from Vietnam, a country has 100s of Year in making encaustic cement tiles, this production in Vietnam is among the best quality in the world. Inheritating long tradition of making encaustic cement tile together with bring new modern technique to production, our Cement tiles have been produced and controlled under the best conditions to guarantee stable quality for all production batches. Basic material are marble powder and pigment, environmental friendly

All patterns and Colors can be customized

Available sizes from 50x50mm to 400x400mm which thickness ranging from 12mm till 25mm

Technical Specifications and Technological Parameters

Specs:

Length 200mm +/-0.5mm

Width 200mm +/-0.5mm

Height 15mm +/-1.0mm

Top Layer 3mm +/-0.1mm

Technological Parameters:

Weight 1200 gr +/- 50gr

Elasticity 1.200 Newton minimum

Shock resistance 30 times minimum

Water Absorption <= 7%

Abrasion +0.45 gr/Cm2

This is ideal material from indoor using or interior which is suitable for restoration of old building or for luxurious building such as hotels, restaurants, cafe or even for boutique or cottage house.

Our capacity: 5,000m2 per month equally to 8 containers 20ft per month.

- Q: So am trying to remodel my bathroom and was wondering if cement board would work better than greenboard as the shower wall? I've read that cement board can be used on floors or kitchen tops but am not sure if I can use it on bathrooms??

- it really depends on what is going on top of the board. if I am using ceramic tile around a tub/shower, I use greenboard. If the tile is granite or porcelain, or will be installed overhead, use wonderboard (cementboard). The additional weight of the tiles could potentially pull the green paper away from the Gypsum. Greenboard is easier to cut For anywhere else i would use either greenboard, or regular drywall and mold/mildew resistant paint, and a new more powerful ceiling exhaust.

- Q: why is cement and water the ingredients of mortar allowed?

- hmmm...oh fick it - there just is no answer to this one.

- Q: What is the formula of cement?

- Unfortunately, there is no easy answer to this question, as there are many different types of cement that vary in the compounds they consist of. But, as an example, here's a breakdown of the chemical formulas used in portland cement. It consists of five compounds as listed below. 50% - Tricalcium silicate - Ca3SiO5 or 3CaO.SiO2 25% - Dicalcium silicate - Ca2SiO4 or 2CaO.SiO2 10% - Tricalcium aluminate - Ca3Al2O6 or 3CaO .Al2O3 10% - Tetracalcium aluminoferrite - Ca4Al2Fe2O10 or 4CaO.Al2O3.Fe2O3 5% - Gypsum - CaSO4.2H2O Hope this gets you started. Good luck.

- Q: As there are many types of cement, i want basic types of cement

- Type 1 - Normal portland cement. Type 1 is a general use cement. Type 2 - Is used for structures in water or soil containing moderate amounts of sulfate, or when heat build-up is a concern. Type 3 - High early strength. Used when high strength are desired at very early periods. Type 4 - Low heat portland cement. Used where the amount and rate of heat generation must be kept to a minimum. Type 5 - Sulfate resistant portland cement. Used where the water or soil is high in alkali.

- Q: I want to do a flooring of my new house by Cement:Sand (1:3)ratio and would like to know the quantity of cement needed per square meter for plastering. The floor thickness will be 2~3mm.

- You need to calculate the volume of your floor Assume a 1 square meter area and assume the thickness is .3 mm (not .2) The volume would then be = 0.0003 m x 1 m x 1m = 0.0003 cubic meters Volumetricly, you need 1/4 part concrete + 3/4 parts sand to equal 0.0003 cubic meters. The concrete volume would then be 0.000075 cubic meters concrete per 1 square meter of floor (at .3 mm thickness).... or 75 cubic centimeters per sq meter The density of Portland cement is about 3 g per cubic centimeter therefore 3 g/cm3 * 75 cm3 = 225 grams or 0.225 kg of cement per square meter of floor

- Q: Is there a difference between cement and concrete?

- Yes there is a big difference. What is the difference between cement and concrete? Although the terms cement and concrete often are used interchangeably, cement is actually an ingredient of concrete. Concrete is basically a mixture of aggregates and paste. The aggregates are sand and gravel or crushed stone; the paste is water and portland cement. Concrete gets stronger as it gets older. Portland cement is not a brand name, but the generic term for the type of cement used in virtually all concrete, just as stainless is a type of steel and sterling a type of silver.

- Q: I want to stain my cement/concrete patio around my pool. What is the best stain to use. I don't want to have to keep redoing it every year.

- you don't stain cement you paint it!! that is why you are having to redo it every year. cement does not absorb things paint is thicker and will stick to the cement.

- Q: I don't know whether to use concrete or cement. It is for a waterfall so it will be constantly subject to moving water, which do you think will be best concrete or cement I'm not sure how long it will last with the winter years and freeze-thaw etc...So basically is cement waterproof enough and will last after constant water going on it?

- cement is the chemical in concrete above is some stuff to read about it they have been using concrete for centuries for fountains

- Q: It is cheaper to build a cement house than wood?

- No a concrete or concrete block building structure is significantly more costly to erect than a frame structure. Depending on where it is located, the concrete building may be more cost-efficient in the longer term due to its greater resistance to termites, wind and fire. It may also be less costly to maintain external finish. Still, there are lots of fine 100 year old frame homes around the country.

- Q: cement rendererAbout us:We are factory with professional Ramp;D team and perfect after-sales service team, We are a manufacturer with national certificate, Each machine is inspected strictly before delivery. You are welcome to visit our factory anytime.cement renderer

- plastering walls with cement cement rendering machine cement for plastering wall plastering machine price cement spraying machine wall plastering machine video cement spray plaster machine plaster rendering machine wall plastering machine india cement rendering tools

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2011 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia; Domestic Market |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Foshan new port, Shenzhen yantian port, Guangzhou huangpu port |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Arabic, Russian |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Vietnam Handmade Cement Tile Language Option French

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meter/Square Meters m²

- Supply Capability:

- 5,000 Square Meter/Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords