High Quality Column Head Mould

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 50000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

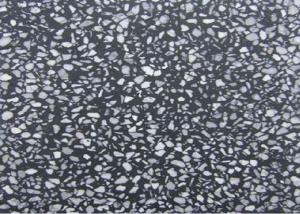

Introduction of High Quality Column Head Mould:

The High Quality Column Head Mould is made of FRP, Silica gel etc. It is used in the production of GRC Component, such as Roman Column Head, Window Frame, Pediment Ornament and Eaves Decorative Rid.

Specifications of High Quality Column Head Mould:

We can offer Mould for Roman Column Head products, diameter size: 300MM 350MM 400MM 450MM 500MM 550MM 600MM. Other sizes can be customized according to customer requirements.

- Q: What type of cement should I use what is waterproof? and What type of glue should I use?

- Check out Fosters Smith aquarium catalog. There are special glues used for marine application. I don't think the the foam or cement will work. The fish will want to eat the foam and you will have to use a special type of cement that is non toxic. Try creating a rock wall with the marine glue. In addition you can make an interesting back drop that is placed behind the glass. Remember what ever you place in the tank will have to be removable so you can clean it. Fish dirt will collect in those areas with no filtration or current.

- Q: for patio what ratio cement +sand+gravel

- I use a 5 to one ratio (five parts gravel, one part cement) the gravel is 60/40 (I assume that is 60 percent sand, 40 % rocks) The moisture content of gravel varies, so difficult to give amount of water.

- Q: What's the difference between concrete and cement?

- one is black and one is gray. now if u cant figure that out, i cant help you.

- Q: In a CSI episode, a guy filled his letter box with cement because his letter box was getting destroyed every night. He had 4 destroyed, had enough and decided to fill the next one with cement. What happened was two guys drove past with a bat, the guy swung to hit the letter box but because it went wrong they crashed and died. The owner buried the letter box, replaced it but of course the CSI team figured it out...and he was arrested. What was the crime he committed? I mean, he had to pay for the replacements so why is he being punished for trying to protect his property? He didn't mean the boys any harm, he was just trying to save his letterbox...

- Some CSI stories (like real life) don't make sense at all. At least they're not suing the cement maker. I wonder what would have happen if the boys had survived, and the letterbox man had actually caught them on video flinging their bats. That would be a happier ending for all.

- Q: will i get crutches from er if i hit my knee cap on the cement step and went to the er or walk in clinic please explain and what if i just go in hopping in on one leg do you think they would give me crutches. do they show you how to use them please explain i want to use crutches

- your stupid. crutches hurt ur under arms and you want to hurt yourself just to use them. go to a big as chemist and buy some.. and yeah your probably would need them, depending on how hard you hit it. your probly need to dislocate it or worse

- Q: Walking pavementTypes of coumpounds or one

- If you want to make cement or 'concrete' for a foot-path: 1 part cement 2 part gravel or sharp stones 3 part sand (not from the beach) You can mix these yourself in a barrow, add the water sparingly, not in big amounts. Don't want the mix too sloppy.

- Q: Our pool liner ripped!! our pool is custom 11ft deep. we drained the pool we are removing the water from behind the liner. We are trying desperatly to make this liner last one more summer! Of course it ripped down at the 11 ft area. but the rip only runs along the top edge of the lip that snaps into the metal ring around the pool. I came up with the idea of using rubber cement to cement the ripped liner to the steel wall. Is this possible?? we just can't shell out 3,700.00 for a liner right now and its HOT the kids are driving us insane to try something ANYTHING does anyone have anybetter ideas?? we are open to any ideas! thanks

- They make vinyl patches that could well work in this case. Have you tried a pool store? As I under stand it you would just put the patch over the rip using heat or glue or both you get a pretty good patch. By that I mean, if the rest of the liner is in good shape you could get years of use from it.

- Q: I am just curious, if I were to use 6 inches of reinforced concrete, making a 'domed tunnel' 100 feet long, how much weight would it be able to support on top? I know a dome can take a lot of weight, but what would be the math formula for figuring this out?Reinforcement would be 5/8quot; steel re-bar creating a skeletal structure to inject cement into and around.

- Portland cement reinforced will have a maximum sustained tensile strength of 2500 PSI. Monolithic dome construction utilizes Gunite which is the same material used for swimming pools, and can withstand 5000 PSI or greater as it must support water's weight of approx. 8 lbs per gallon.

- Q: Im screwing masonite to sheetrock then going over the masonite with a sheet of 4x8 laminate. This is on a wall. I want an adhesive that will give me at least 30sec to get it set right and square. But i dont want an adhesive I have to have constant pressure on for an hour either. Someone told me linoleum adhesive ? I do not want to use contact cement im a newby and need the workability time to get it on right.

- Laminate Contact Cement

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2006 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality Column Head Mould

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 50000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords