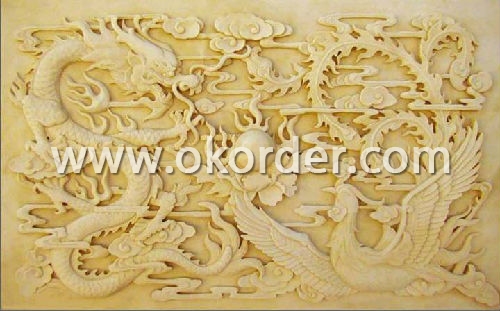

Pediment Ornament Mould For Wall Decoration

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 5000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction Of Pediment Ornament Mould For Wall Decoration:

GRC material has excellent constructive performance in history of building construction. With high strength and good nature, it is fireproof, mildew and worm resistant, moisture proof, and sound and heat insulated. It can be processed by nailing, adhering and patching, thus it is easy and convenient in construction.

Description Of Pediment Ornament Mould For Wall Decoration:

High strengh

Corrosion resistance, anti-frost and waterproof

Natural and hand crafted

Durable

Component Of Pediment Ornament Mould For Wall Decoration:

Glass Fibre Reinforced Cement(Cement, Alkali Resistant Glass Fibre / protofilament), short for GRC/GFRC

Advantage Of Pediment Ornament Mould For Wall Decoration:

Strong, Tensile-strength: 1800 Mpa, twice to triple as much as that of steel fibre.

S. G.: 2.7

Durability: Over 10 years

High heat-resistant: Its softening point is about 860

Anti-frost, waterproof&fireproof, mildew&worm and corrosion resistance

UV-protection&environment friendly

Maintenance free

Customer designs are available. Our products are very popular with domestic and abroad market. We have built a steady and long-term cooperation relationships with Chinese top 20 real estate companies and our products are exported to the Middle East, Western Europe, North America, South Africa and other countries and regions.

- Q: How do u gt plastic model cement off of the windows of a plastic model?

- Glued parts can't be unglued, as the glue melts and welds the plastic together. Go slow, and be patient. Or, go with plan B of battle damage.

- Q: Will they die and just fall over?

- yes . PLants need soil and water . cement lack both !

- Q: ok im thinking of remodeling and there is a hideous cement floor, i want a carpet...How do i do it? thank you

- install tack strip, lay padding, install carpet. They make tack strip with concrete nails(hardened nails to drive into concrete)

- Q: or can i just start laying it directly on top of the cement floor?

- No. You may want to apply a waterproofing to the slab first. Make sure it is compatible with tile mastic.

- Q: Was there concrete/cement in the 1880s-1890s?

- Uh oh. She forgot the Romans in her History of concrete. Their concrete work is still standing. :) But I liked the story. I know you asked about the 1800's, but if you are also interested in Roman (cementitious) concrete history, here's an interesting site from the University of Santa Barbara: id-archserve.ucsb.edu/arthistory/...

- Q: What do I do? Is it harmful?

- Take it to a emergency hospital. Yes, rubber cement being swallowed would be harmful to both humans or other mammals. I suggest you first call a vet to make sure, and then do as they instruct, even if it would be just as the following said take it to the emergency hospital. I suggest calling the vet first, just in case.

- Q: what is the difference between concrete and cement and stuco?

- Same thing, different texture and application of it on cinder-block and stucco. Some cement is rough, though, to be used for a walk so it is not slippery.

- Q: How is Portland Cement made? What is the difference between concrete and Portland Cement?

- Portland cement is the most common type of cement in general usage in many parts of the world, as it is a basic ingredient of concrete, mortar, stucco and most non-specialty grout. It is a fine powder produced by grinding Portland cement clinker (more than 90%), a limited amount of calcium sulfate which controls the set time, and up to 5% minor constituents (as allowed by various standards). Portland cement, the basic ingredient of concrete, is a closely controlled chemical combination of calcium, silicon, aluminum, iron and small amounts of other ingredients to which gypsum is added in the final grinding process to regulate the setting time of the concrete. Lime and silica make up about 85% of the mass. Common among the materials used in its manufacture are limestone, shells, and chalk or marl combined with shale, clay, slate or blast furnace slag, silica sand, and iron ore. Portland was developed from cements (or correctly hydraulic limes) made in Britain in the early part of the nineteenth century, and its name is derived from its similarity to Portland stone, a type of building stone that was quarried on the Isle of Portland in Dorset, England. Joseph Aspdin, a British bricklayer, in 1824 was granted a patent for a process of making a cement which he called Portland cement. In its simplest form, concrete is a mixture of paste and aggregates. The paste, composed of portland cement and water, coats the surface of the fine and coarse aggregates. Through a chemical reaction called hydration, the paste hardens and gains strength to form the rock-like mass known as concrete. Within this process lies the key to a remarkable trait of concrete: it's plastic and malleable when newly mixed, strong and durable when hardened. These qualities explain why one material, concrete, can build skyscrapers, bridges, sidewalks and superhighways, houses and dams.

- Q: Please any one says me Chemical composition of Portland cement?

- Typical constituents of and Portland cement Mass% Calcium oxide, CaO 61-67% Silicon oxide, SiO2 19-23% Aluminum oxide, Al2O3 2.5-6% Ferric oxide, Fe2O3 0-6% Sulfate 1.5-4.5%

- Q: where do you buy dental cement?

- This Site Might Help You. RE: where do you buy dental cement?

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2006 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Pediment Ornament Mould For Wall Decoration

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 5000000 Sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords