Wall Props

Wall Props Related Searches

Construction Props Scaffolding Props Tilt Panel Props Plasterboard Props Tilt Panel Props For Sale Soundproofing A Wall Peri Push Pull Props Peru Props High Performance Boat Props Props For Sale Uk Acoustic Padding For Walls Shoring Props For Sale Plastic Wall Corner Protectors Shisham Props Mirror Corner Protectors Wall Sconces Living Room Stainless Steel Wall Guards Fabricated Wall Panels Soundproofing Homes Mercury Props For Sale Bass Boat Props For Sale Best Wall Insulation Track Lighting For Walls Soundproof Curtains Used Yamaha Props For Sale Boat Prop Guard Pvc Walls and Ceilings 4 Blade Prop Rmd Push Pull Props Wall Lights For BedroomsWall Props Supplier & Manufacturer from China

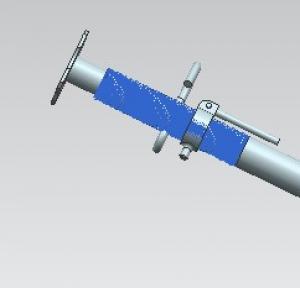

Wall Props are a range of products designed to provide structural support and reinforcement in various construction and renovation projects. These props are engineered to bear the weight of walls, ceilings, and other structural elements, ensuring stability and safety. They are commonly used in residential and commercial buildings, as well as in the construction of bridges and other infrastructure projects.The application and usage scenarios for Wall Props are diverse, making them an essential tool in the construction industry. They can be used to support new structures during construction, reinforce existing structures to prevent collapse, or provide temporary support during renovations. Wall Props are also used in the installation of formwork, shoring, and falsework, ensuring that the construction process is both efficient and secure. Their versatility and durability make them a popular choice among contractors and builders.

Okorder.com is a leading wholesale supplier of Wall Props, offering a vast inventory of high-quality products to meet the needs of various construction projects. With a commitment to providing top-notch customer service and competitive pricing, Okorder.com has established itself as a reliable source for Wall Props and other construction materials. By partnering with reputable manufacturers, Okorder.com ensures that their products meet the highest industry standards, providing customers with the assurance of quality and reliability.

Hot Products