Construction Heavy Duty Support Steel Props

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

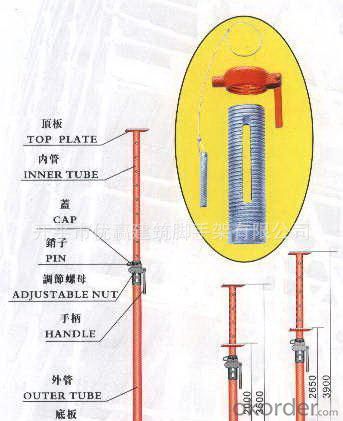

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q: Can steel props be used in high-rise buildings?

- Yes, steel props can be used in high-rise buildings. Steel props, also known as adjustable steel columns or steel shores, are commonly used in construction projects to provide temporary support to beams, slabs, walls, and other structural components. These props are highly versatile and can be adjusted to different heights, making them suitable for use in buildings of varying sizes, including high-rise structures. Steel props are designed to withstand heavy loads and provide stability during construction. They are made from high-quality steel, which provides excellent strength and durability. The props can be easily adjusted to the desired height and locked in place to provide support to the structure. Additionally, steel props can be used in conjunction with other support systems, such as scaffolding or formwork, to ensure the stability and safety of high-rise buildings during construction. It is important to note that the use of steel props in high-rise buildings should be done in accordance with the engineering and safety guidelines. Proper calculations and analysis should be carried out to determine the appropriate size, load capacity, and spacing of the props to ensure the structural integrity of the building. Consulting with a structural engineer or a construction professional is crucial to ensure that steel props are used correctly and safely in high-rise construction projects.

- Q: How do steel props compare to modular support systems in terms of flexibility?

- Flexibility is a key consideration when it comes to steel props and modular support systems. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction projects to support and stabilize structures. They are versatile and can easily be adjusted to different heights, making them suitable for a variety of projects and applications. Steel props can be extended or shortened as needed, providing flexibility to accommodate various construction needs. Additionally, they are lightweight and easy to handle, making transportation and installation on-site convenient. On the other hand, modular support systems offer a more comprehensive and flexible solution for supporting structures. These systems consist of prefabricated components that can be assembled and reconfigured to meet specific project requirements. Modular support systems provide a wider range of options in terms of design, size, and load capacity, allowing for greater adaptability to different project conditions. They can be easily adjusted and modified to accommodate changes in the construction process, providing a high level of flexibility. While steel props are suitable for simple support tasks, modular support systems are more versatile and can handle more complex and demanding construction projects. They offer a higher degree of flexibility in terms of adapting to various site conditions, load requirements, and design specifications. However, it is important to note that modular support systems may require more planning and coordination during installation and may be more expensive compared to steel props. In conclusion, steel props provide a satisfactory level of flexibility for many construction projects. However, for more complex and demanding projects, modular support systems offer a higher degree of flexibility and adaptability. Ultimately, the choice between steel props and modular support systems depends on the specific requirements and constraints of the project at hand.

- Q: Can steel props be used in high-rise construction?

- High-rise construction can indeed utilize steel props. These props, referred to as adjustable steel props or telescopic steel props, are frequently employed in construction for the purpose of providing temporary support to structures during renovation or construction work. Their design allows them to endure heavy loads and be adjusted to various heights, rendering them suitable for high-rise construction projects. By supplying stability and support to both vertical and horizontal loads, steel props guarantee the safety and structural integrity of the building throughout the construction process. Moreover, steel props offer versatility as they can be easily installed, dismantled, and repositioned as needed. Consequently, they have become a popular choice in high-rise construction due to their flexibility and adaptability.

- Q: A17-57 circular column formwork supporting wood, plywood is converted into steel support how to convert?

- Item number is different, but there is one thing you have to pay attention to.

- Q: Can steel props be used for temporary support in industrial facilities?

- Temporary support in industrial facilities can be provided by steel props. These adjustable steel props, also known as steel shoring props, are commonly used in construction and industrial settings. They are used to provide temporary support to structures, walls, ceilings, or heavy loads. Made of high-quality steel, these props have strong load-bearing capabilities. They can be easily adjusted to different heights to meet various support requirements. Steel props prove to be particularly useful in industrial facilities during maintenance, repairs, or renovations. They can be installed and adjusted effortlessly to provide additional stability to structures or equipment. Moreover, steel props are designed to have a high load-bearing capacity, making them suitable for supporting heavy loads commonly found in industrial facilities. Their sturdy construction allows them to withstand significant weight, making them a reliable choice for temporary support. However, it is essential to note that steel props are intended for temporary use only and should not be considered a long-term solution. Regular inspections are necessary to ensure their good condition and proper adjustment for maintaining stability. Safety guidelines should always be followed, and consultation with structural engineers or professionals is advised to determine the appropriate size, quantity, and placement of steel props for specific industrial facilities.

- Q: Are steel props suitable for use in tunnel ventilation system installation?

- Yes, steel props are suitable for use in tunnel ventilation system installation. Steel props provide strong support and stability, making them ideal for holding up ventilation equipment and ensuring the safe and efficient operation of the system within tunnels.

- Q: How to calculate the weight per meter of steel support

- Depending on the type of steel used for supporting, the weight of the different models is different

- Q: Can steel props be used on uneven surfaces?

- Yes, steel props can be used on uneven surfaces. Steel props are adjustable and can be extended or shortened to fit various heights and angles. This flexibility allows them to be used on uneven surfaces by adjusting the length of the props accordingly.

- Q: Can steel props be used in both residential and commercial construction projects?

- Yes, steel props can be used in both residential and commercial construction projects. Steel props, also known as adjustable steel shoring posts or acrow props, are commonly used to support temporary structures or provide additional support during construction or renovation work. These props can be adjusted in height and are made of durable and strong steel, allowing them to bear heavy loads. Due to their versatility and strength, steel props are suitable for a wide range of applications, including both residential and commercial construction projects. They can be used to support formwork, scaffolding, beams, walls, and other structural elements in buildings of various sizes. Whether it is for constructing a residential home, office building, retail complex, or any other commercial structure, steel props offer a reliable and efficient solution for temporary support needs.

- Q: Do steel props have any safety instructions or guidelines for use?

- Indeed, safety instructions and guidelines exist for the use of steel props. Steel props, also referred to as steel adjustable props or steel acrow props, are commonly utilized in construction and scaffolding to offer support to temporary structures or reinforce existing ones. To ensure the safety of workers and the stability of the structure, it is crucial to follow specific safety instructions and guidelines when employing steel props. Below are several common safety instructions and guidelines for using steel props: 1. Thorough Inspection: Prior to using steel props, it is essential to conduct a comprehensive inspection to identify any signs of damage, such as cracks, bends, or rust. Any damaged or faulty props should not be utilized as they may compromise the stability of the structure. 2. Proper Setup: Steel props should be set up correctly in accordance with the instructions provided by the manufacturer. They need to be placed on a solid and level surface, with the adjustable section fully extended and the base plate securely positioned. The props should be firmly tightened to ensure stability. 3. Load Capacity: Each steel prop has a specific load capacity which must never be exceeded. It is important to verify the load capacity of the prop and ensure it is suitable for the intended use. Overloading a prop can lead to structural failure and accidents. 4. Bracing and Support: Adequate bracing and support should be provided for steel props to prevent any lateral movement or collapse. Depending on the height and load of the structure, additional bracing, such as diagonal struts or cross-bracing, may be necessary. This helps distribute the load evenly and enhances stability. 5. Regular Inspections: Regular inspections should be carried out during the use of steel props to assess their condition. Any signs of damage, movement, or instability should be promptly addressed, and appropriate measures should be taken to rectify the issue. 6. Proper Storage and Handling: When not in use, steel props should be stored in a dry and well-ventilated area to prevent rust and corrosion. They should be handled with care to avoid any damage that may compromise their structural integrity. It is important to note that these safety instructions and guidelines may vary depending on the specific manufacturer and the local regulations governing construction and scaffolding practices. Therefore, it is essential to consult the manufacturer's instructions and adhere to any additional safety guidelines provided by regulatory authorities in your region.

Send your message to us

Construction Heavy Duty Support Steel Props

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords