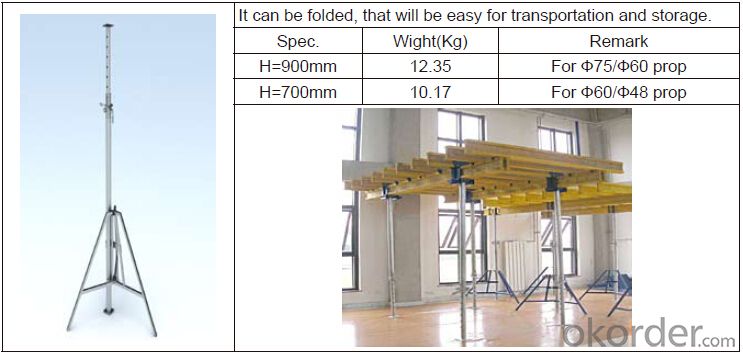

Steel Prop & Tripod for build formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Prop & Tripod & Beam Clamp

(1) Steel prop is a vertical support system widely used in construction.

Characteristics:

◆ Simple & flexible structure

◆ Easy & fast operation

◆ Economical efficiency

◆ Easy storage and transportation

◆ Reasonable load-bearing capacity

(2) Tripod is always used as support for steel prop.

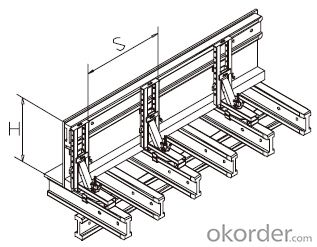

(3) The beam clamp is a technical instrument for supporting beam formwork

which makes conventional beam formwork simple, and increases the construction

efficiency.

Characteristics:

◆ Flexible structure

◆ Optimum design proposal

- Q: Can steel props be used in both indoor and outdoor environments?

- Indeed, steel props are applicable in both indoor and outdoor settings. Steel, known for its adaptability and resilience, can endure diverse weather conditions, rendering it appropriate for outdoor utilization. Whether it entails bolstering temporary frameworks like scaffolding or formwork, or providing temporary assistance while undertaking construction or renovation ventures, steel props can be employed both indoors and outdoors. Furthermore, the corrosion-resistant qualities of steel guarantee its endurance and dependability, even in outdoor surroundings exposed to moisture or severe elements.

- Q: Can steel props be used for supporting temporary fencing or barriers?

- Indeed, temporary fencing or barriers can benefit from the utilization of steel props. Renowned for their resilience and longevity, these props prove to be optimal for offering assistance to impermanent structures. They effortlessly bear the load of temporary fences or barriers, guaranteeing stability and safeguarding. Moreover, steel props possess the ability to be adjusted to varying heights, enabling adaptability when installing temporary fencing or barriers in diverse settings and terrains. All in all, steel props emerge as a trustworthy selection for supporting temporary fencing or barriers.

- Q: How do you dismantle a steel prop safely?

- To ensure the safe dismantling of a steel prop, follow the steps outlined below: 1. Prioritize safety precautions: Before commencing the dismantling process, equip yourself with the necessary personal protective gear (PPE) including safety goggles, gloves, and a hard hat. Additionally, create a clear work area and identify any potential hazards. 2. Evaluate the prop: Examine the structure and components of the steel prop to gain a comprehensive understanding. Identify any locking mechanisms, pins, or bolts that require removal. 3. Release the load: If the steel prop is supporting any weight, carefully release the load by gradually lowering it onto a stable surface. This will ensure that the prop is not strained during the dismantling process. 4. Eliminate locking mechanisms: Steel props often feature locking mechanisms that secure their components together. Utilize appropriate tools such as wrenches or spanners to locate and remove any locking pins, bolts, or nuts. 5. Disassemble the prop: Once all locking mechanisms have been removed, begin disassembling the prop by separating its components. Start from the top and work your way down, meticulously unscrewing or unbolting each section. 6. Adhere to the manufacturer's instructions: Some steel props may come with specific instructions or guidelines provided by the manufacturer for safe dismantling. If available, consult these instructions to ensure compliance with the recommended dismantling procedure. 7. Employ mechanical aids if necessary: Depending on the size and weight of the steel prop, you may need to utilize mechanical aids such as cranes, hoists, or lifting equipment to safely handle and move the components during dismantling. 8. Store or dispose of the components: Once the steel prop has been fully dismantled, arrange the components in a safe and organized manner. Store them appropriately for future use or dispose of them in accordance with local regulations and guidelines. Always prioritize safety when dismantling any structure or equipment. If you are unsure about any step or lack the necessary experience, consult a professional or seek guidance from an expert in the field.

- Q: What is the meaning of steel support flange connection

- One end of the fixing end is a movable end, and the middle section is a different standard pipe section

- Q: How long can steel props be left in place?

- Steel props can generally be left in place for as long as they are structurally sound and meet the requirements of the specific construction project. However, it is important to regularly inspect and assess the condition of the props to ensure their continued safety and effectiveness.

- Q: Are steel props suitable for supporting temporary staircases or access ramps?

- Yes, steel props are suitable for supporting temporary staircases or access ramps. Steel props are strong and durable, making them ideal for providing stable support for such structures.

- Q: Can steel props be used for temporary support during foundation work?

- Yes, steel props can be used for temporary support during foundation work. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to provide temporary support to structures, such as walls, ceilings, or floors, during various stages of construction. These props are adjustable in height, making them versatile and suitable for different construction projects. When it comes to foundation work, steel props can be used to provide temporary support to the foundation walls and beams while excavation or other foundation-related activities are being carried out. They help distribute the load and prevent the structure from collapsing or experiencing excessive movement during the construction process. Steel props are preferred for temporary support during foundation work because they are sturdy, strong, and can withstand heavy loads. They are also quick and easy to install, adjust, and remove, making them a cost-effective solution for temporary support needs. Additionally, the adjustable feature of steel props allows for fine-tuning the height to suit the specific requirements of the construction project. However, it is important to note that the use of steel props for temporary support during foundation work should be done in accordance with engineering guidelines and under the supervision of professionals. Proper calculations and assessment of the load-bearing capacity of the steel props should be conducted to ensure their suitability and safety for the specific construction project.

- Q: How do you secure a steel prop in place?

- To secure a steel prop in place, there are a few steps you can follow: 1. Choose the right size and type of steel prop: Ensure that the prop you select is the appropriate size and type for the task at hand. The prop should be able to support the weight and load it will be subjected to. 2. Positioning: Place the steel prop in the desired location, ensuring it is aligned properly and in the correct orientation. Make sure it is positioned on a stable and level surface that can bear the weight. 3. Adjust the height: Extend or retract the prop to the desired height. Most steel props have an adjustable screw mechanism that allows you to adjust the height according to your requirements. 4. Tighten the prop: Once the prop is at the correct height, secure it in place by tightening the locking mechanism. This could involve turning a handle, tightening a nut, or using a locking pin, depending on the specific design of the steel prop you are using. 5. Check stability: After securing the prop, check its stability to ensure it is firmly in place. Give it a gentle shake or push to see if it remains steady. If it wavers or seems unstable, reposition or adjust it until it is secure. 6. Test load-bearing capacity: If your task involves placing a load on the steel prop, it is important to test its load-bearing capacity. Gradually add the load while monitoring the prop's stability. Avoid exceeding the recommended maximum load capacity to prevent any accidents. 7. Regular inspections: Periodically inspect the steel prop to ensure it remains secure and in good condition. Look for any signs of wear, damage, or loosening of the locking mechanism. If any issues are detected, address them promptly to maintain the prop's stability and safety. Following these steps will help you effectively secure a steel prop in place, ensuring stability and safety for your construction or support needs.

- Q: What are the common causes of failure in steel props?

- Common causes of failure in steel props include excessive loads or overload, corrosion due to exposure to moisture or chemicals, improper installation or inadequate support, fatigue from repeated use or stress, and manufacturing defects.

- Q: In the construction of steel support foundation pit excavation pit, with larger width, in the foundation pit is arranged in the middle of a row of piles, pile top reinforced concrete beam, my question is: can the top steel support beam on it, feel it should not, steel support should be at the top of the crown beam and steel Wai the purlin, bear it in beam top. Where is the specification?

- You are the construction, then according to the construction, do not understand, please explain the design.Specification above can not say no.

Send your message to us

Steel Prop & Tripod for build formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords