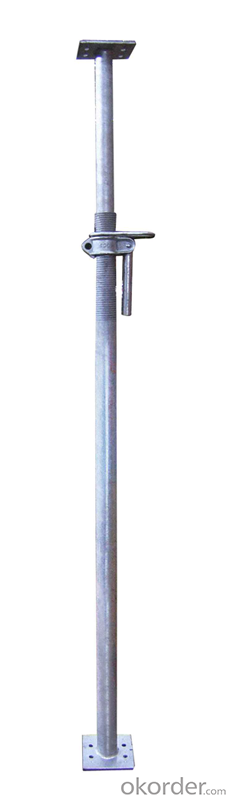

Construction Support Steel Props of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Props:

1. Steel Prop consists of internal pipe, external pipe, prop sleeve, nut, pin, top and bottom plate.

2. Steel Prop is widely used as support system in beam, slab, formwork, concrete and floor support.

3. Steel Prop can be surface treatment red oil painting or powder coated or galvanized to further resist rust, cracking and corrosion, has no pollution or harm to the environment and human body, which make sure of its low damage and longer life span.

4. Steel Prop has fewer components, easy and quick assembly.

5. Steel Props has high bearing capacity, as steel pipe material is Q235, thickness can be 1.8mm to 3.0mm, diameter 40-48mm,48-56mm,48-60mm. According to SGS test report, one prop with 2.2mm of thickness, 48-60mm diameter can load 1.8tons, which is heavy duty Steel Props .

6.We can meet all kinds of steel props , Italian tye, Spanish type for South Amercia, Middle East type. aole the requiremnets, such as U head, fork head, rosette head, plate, etc.

Technical parameters

Model Number: adjustable steel prop

Material: Q235 steel tube raw material

Surface Treatment: Galvanized,Dip Painted,Powder coated

Color: silver,dark red,yellow,blue,green and more colore

Application: building construction shoring props for inside concrete wall support

tube thickness: 1.8/2.0/2.2/2.5/3.0mm

adjustable length: 1600-2900/1800-3200/2000-3600/2200-4000mm as your request

base plate size: 120*120*5mm or as your request

Working life: 4-6 years normally

inner tube diameter: 40mm,or 48mm

outer tube diameter: 48mm,or 56/58/60mm

Packaging & Delivery

In bulk or steel pallet. props will be bundle with wooden pallet or bare package in container one 20ft container can load steel props 1800pcs to 2500pcs.

20 to 30 days to main port of China after order confirmation

- Q: Can steel props be used in the construction of tunnels or underground passages?

- Tunnels or underground passages can indeed utilize steel props. These props, frequently employed in construction projects like tunnels and underground passages, serve as both temporary and permanent support systems. Their purpose is to ensure stability, strength, and load-bearing capacity, thus guaranteeing the structure's safety during construction and in the long run. Given their adjustability, steel props are easily installed and removed, making them suitable for a variety of underground construction applications. Furthermore, steel, being both durable and robust, can withstand the challenging conditions often encountered in tunneling projects, such as high pressure, ground movements, and vibrations. In summary, steel props are a dependable and widely used solution for supporting tunnels and underground passages during construction.

- Q: Are steel props easy to assemble and disassemble?

- Generally, steel props are easy to assemble and disassemble. They are commonly used in construction to provide temporary support or hold formwork during concrete pouring. Steel props, also known as adjustable steel props or steel shore props, consist of two main components: the inner tube and the outer tube. The inner tube is threaded and can be adjusted to the desired height by rotating it. The outer tube is fixed and provides stability and support. Assembling the steel props is simple. Extend the inner tube to the desired height and tighten it by twisting it clockwise. This locks the inner tube in place and provides support. Disassembling the steel props is equally easy. Loosen the inner tube by rotating it counterclockwise. This allows it to retract back into the outer tube, reducing the height of the props for easier handling and removal. In addition, steel props are lightweight and portable, which further simplifies the assembly and disassembly process. They are made from high-quality steel, ensuring durability and strength. Overall, steel props are user-friendly and can be quickly assembled and disassembled, making them a practical choice for various construction applications.

- Q: What are the typical uses of steel props?

- Steel props, which are sometimes referred to as adjustable steel props or telescopic props, find common usage in construction and building projects as temporary supports. Their main purpose is to offer vertical load-bearing support and stability to structures at various stages of construction and renovation. A prime application of steel props involves providing temporary support to beams, slabs, and ceilings while load-bearing walls are being removed or replaced. Throughout this process, steel props are strategically positioned to distribute the load and prevent any structural instability. This guarantees the safety of workers and the integrity of the building. Another prevalent use of steel props lies in formwork systems. Formwork refers to the temporary structure that bears the weight of concrete during pouring and curing. Steel props are employed to carry the weight of the formwork and uphold its position until the concrete sets. Their adjustability enables workers to easily modify the height of the props according to the necessary level. Furthermore, steel props are regularly employed in shoring applications. Shoring involves temporarily supporting an existing structure that has been weakened or compromised. Steel props can be utilized to stabilize walls, floors, or roofs that are undergoing repairs or renovations. They aid in redistributing the load and preventing further damage or collapse. Steel props also serve as temporary supports during excavation work. They can be vertically placed to provide support to trenches, thus preventing cave-ins and ensuring worker safety. Adjustable props are particularly advantageous in this context as they facilitate easy adaptation to different trench depths. To summarize, steel props are typically used to provide temporary support during the removal or replacement of load-bearing walls, support formwork systems, shore weakened structures, and stabilize trenches during excavation work. These versatile and adjustable supports play a critical role in ensuring the safety and stability of construction projects.

- Q: Can steel props be used to support ceilings?

- Ceilings can indeed be supported by steel props. These props, also referred to as adjustable steel props or acrow props, are frequently utilized within the construction industry to offer temporary support to structures, including ceilings. Their purpose is to allow for height adjustment, enabling extension or retraction to the desired length. This adaptability renders them suitable for supporting ceilings of varying heights and weights. Steel props possess durability and sturdiness, enabling them to withstand substantial loads. Consequently, they are an excellent option for providing temporary support during construction or renovation projects. Moreover, their versatility and user-friendly nature have made them a favored choice among contractors and builders for supporting ceilings and other structural components.

- Q: How do you ensure proper weight distribution when using steel props?

- To achieve appropriate weight distribution while utilizing steel props, it is imperative to adhere to a few significant guidelines: 1. Selection of suitable size and type of steel props is crucial. The specific load requirements of the structure must be considered when choosing props. Take into account the load's height, weight, and dimensions, and ensure that the props possess the necessary load-bearing capacity. 2. Correct positioning of the props is essential for even weight distribution. Place the props at regular intervals along the load-bearing structure, ensuring they are evenly spaced and aligned. This will evenly distribute the weight and prevent excessive stress on any individual prop. 3. Leveling the props is of utmost importance. Ensure that the steel props are level and perpendicular to the load-bearing structure. Utilize a spirit level or laser level to assess and adjust the props as needed for a level position. This will evenly distribute the weight and prevent any tilting or imbalance. 4. Firmly secure the props to the load-bearing structure once they are positioned and leveled. This can be accomplished by using adjustable clamps or threaded rods to tightly hold the props in place. Proper securing will prevent any movement or shifting of the props, thereby maintaining proper weight distribution. 5. Conduct regular inspections and monitoring of the steel props to ensure ongoing proper weight distribution. Check for any signs of damage, excessive deflection, or uneven weight distribution. Make necessary adjustments or replacements if required. In conclusion, the attainment of proper weight distribution when employing steel props necessitates meticulous selection, accurate positioning, leveling, secure fastening, and regular monitoring. By adhering to these steps, one can securely and efficiently distribute the weight, preserving the structural integrity of the supported load.

- Q: What are the common maintenance practices for steel props?

- Common maintenance practices for steel props include regular cleaning and inspection to remove dirt, rust, and any other contaminants. It is important to lubricate the moving parts to prevent friction and ensure smooth operation. Regular checks should be conducted to identify any damage or wear and tear, and repairs or replacements should be made promptly. Additionally, storing the props in a dry and well-ventilated area helps to prevent corrosion and prolong their lifespan.

- Q: Is not the 10-4-100 constructional column composite formwork steel support, how to calculate the price?Is not a fixed price deduction combination of steel and wood composite template? 314.16-5.6*2.03-35*0.193=296.037 formula of the 5.6 and 35 how come?

- Third, your understanding is right. The fixed price includes human machine, unlike the list is single, the quota is generally comprehensive unit price.So, the fixed price deduction combination of steel and wood composite template such understanding is right.314.16-5.6*2.03-35*0.193=296.037 is 5.6 and 35, these two quantities should be the combination of steel and wood composite board price.5.6 deduction and 35 price is 2.03, and 0.193 is the amount of engineering. So, you should be able to understand

- Q: Do steel props have any safety features for preventing accidental collapse?

- Yes, steel props have several safety features in place to prevent accidental collapse. These features are designed to ensure the stability and reliability of the props during construction or renovation projects. One safety feature is the adjustable height mechanism, which allows the prop to be set at the desired height and locked securely in place. This mechanism ensures that the prop remains stable and prevents any sudden or accidental collapse. Additionally, steel props are often equipped with a load-bearing capacity indicator. This indicator provides a clear indication of the maximum weight that the prop can safely support. By adhering to this weight limit, the risk of accidental collapse due to overloading is minimized. Furthermore, steel props are typically made from high-quality steel materials that are known for their strength and durability. These props undergo rigorous testing and quality control measures to ensure that they meet industry standards and can withstand heavy loads without compromising safety. It is important to note that while steel props have safety features, it is crucial for workers and construction personnel to follow proper installation guidelines and adhere to safety protocols. Regular inspections and maintenance should also be conducted to identify any potential issues or signs of wear and tear that may compromise the safety of the props. By following these precautions, the risk of accidental collapse can be significantly reduced.

- Q: Can steel props be used for supporting temporary fences or barriers?

- Yes, steel props can be used for supporting temporary fences or barriers. Steel props are strong and durable, making them suitable for providing stable support to temporary structures like fences or barriers. They can withstand heavy loads and offer a reliable solution for ensuring the stability and security of temporary fencing or barriers.

- Q: What are the safety precautions to be taken while using steel props?

- To ensure the safety of workers and the stability of the supported structure, it is important to take several safety precautions when using steel props. These precautions include: 1. Inspection of props: It is crucial to thoroughly examine steel props before use to identify any signs of damage or defects. This includes checking for cracks, deformities, or any other issues that could compromise their structural integrity. Damaged props should not be used and must be replaced or repaired. 2. Correct installation: Proper installation of steel props is essential and should be done according to the manufacturer's instructions. This involves securely connecting the props to the supported structure, ensuring proper alignment and tightening. Additionally, props should be placed on stable and level ground to prevent instability or collapse. 3. Load capacity consideration: Each steel prop has a specified load capacity that should not be exceeded. Careful calculation and distribution of the load is necessary to avoid overloading the props. Exceeding the load capacity can result in structural failure and potential accidents. 4. Regular inspections: Regular inspections should be conducted to monitor the condition of steel props during use. This includes checking for signs of wear and tear, such as rust or corrosion, and immediately replacing or repairing any damaged or compromised props. 5. Proper storage and transportation: Steel props should be stored in a dry and secure location to prevent damage and deterioration. During transportation, they should be adequately secured to prevent movement or damage that could affect their structural integrity. 6. Training and supervision: Workers responsible for using steel props should receive proper training on their correct usage and safety precautions. They should also be supervised during installation and use to ensure compliance with all safety measures. By following these safety precautions, the risk of accidents or structural failures while using steel props can be minimized, creating a safe working environment for all workers involved.

Send your message to us

Construction Support Steel Props of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords