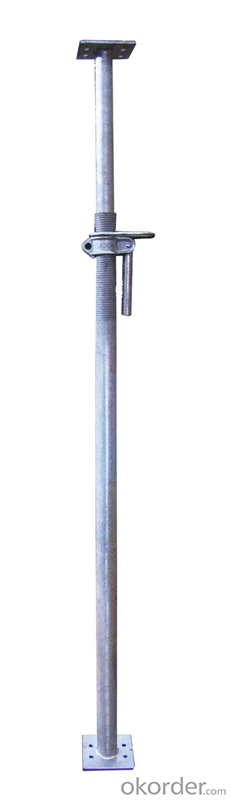

Adjustable Steel Props of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product information:

Model Number: GTJ-P003

Name: Q235 High Quality Steel Slab Props

Material: Q235

Thickness: 1.6mm to3mm or as your requirements

Surface Treatment: as per requirements

Standard: use your standard or international standard

Dimension: Light duty 40-48mm, MID Duty 48-56/58mm, Heavy duty 48-60mm

Characteristics:

1. Reliable performance

2. Corrosion resistance

3. Durable finish standards

Functions

It is used for construction supporting, timber, formwork, concrete slab and so on. It is very easy and reliable to use

Why Choose Us

1. We are experienced manufacturer in Hebei with more than 4 years experience and cooperating with more many countries.

2. We supply qualified products which are certified by SGS and ISO9001:2008. Strict QC to make sure your profit.

3. Timely delivery can be guaranteed because we have a factory which covers an area of 30000sqm and its daily output is more than 50 tons.

4. A competitive price can be offered because we are a professional manufacturer of scaffolding with an advantage on cost-controlling & production management.

- Q: Can steel props be used for temporary support during pipe installation?

- Yes, steel props can be used for temporary support during pipe installation. Steel props provide sturdy and reliable support, making them suitable for holding pipes in place until they are properly secured.

- Q: What is the purpose of a steel prop in construction?

- The primary function of a steel prop in construction is to offer temporary support during different stages of construction or renovation. These props, also referred to as adjustable steel props or steel shore, are commonly utilized to bear vertical loads like beams, slabs, walls, or formwork. Their height can be adjusted, allowing for extension or retraction as required to provide the necessary support. They are designed to be easily installed, adjusted, and dismantled, making them an adaptable and cost-efficient solution. Steel props are frequently employed in construction projects to guarantee the stability and safety of structures by preventing excessive deflection or collapse. They aid in distributing the load evenly and transferring it to a stable foundation, thereby minimizing the risk of structural failure or damage. Moreover, steel props are often used in conjunction with other construction equipment, such as scaffolding or formwork systems, to establish a secure and stable working environment for construction workers. They offer additional support and reinforcement to ensure the integrity of the structure during construction activities. To summarize, the purpose of a steel prop in construction is to provide temporary support, enhance structural stability, and ensure the safety of workers and the structure itself.

- Q: What is the maximum angle of inclination that a steel prop can withstand?

- The ability of a steel prop to withstand an angle of inclination is influenced by various factors, including the specific type and quality of steel used, the dimensions and design of the prop, and the load it bears. Steel props are typically engineered to endure significant angles of inclination without failure, as they are commonly employed in construction and engineering to support heavy loads and provide stability. Nevertheless, it is crucial to recognize that surpassing the recommended angle of inclination can compromise the prop's structural integrity and potentially lead to failure or collapse. To ascertain the maximum angle of inclination for a steel prop, it is imperative to consult the manufacturer's specifications and guidelines. These specifications will furnish the necessary information concerning the prop's load-bearing capacity, the highest allowable angle of inclination, and any other pertinent limitations or considerations. In conclusion, the maximum angle of inclination that a steel prop can endure is not a fixed value but relies on numerous factors. It is imperative to consult the manufacturer's guidelines and adhere to the recommended specifications to ensure the secure and efficient utilization of the steel prop.

- Q: How do steel props compare to other types of support systems?

- Steel props have gained high regard in the construction industry due to their superior strength, durability, and versatility compared to other support systems. One primary benefit of steel props lies in their exceptional load-bearing capacity. They are specifically designed to endure heavy loads and offer reliable support to structures during construction or renovation endeavors. This makes them particularly suitable for providing support to large beams, slabs, and columns. Furthermore, steel props provide a wide range of adjustable heights and extensions, enabling precise leveling and support in various construction scenarios. These props can be effortlessly adjusted to the required height and securely locked in position, guaranteeing stability and safety throughout the construction process. When compared to other support systems like wooden or concrete props, steel props exhibit greater resistance to deformation, bending, and compression. Their sturdy construction and high-quality materials make them less prone to damage or failure, thus providing a more secure and dependable support solution. Additionally, steel props are lightweight and easy to handle, making them convenient to transport, assemble, and disassemble. They require minimal labor and time, contributing to enhanced efficiency and productivity on construction sites. Another advantage of steel props stems from their reusability. Unlike wooden or concrete props, which may deteriorate over time and require replacement, steel props can be used repetitively, making them a cost-effective option in the long term. This reusability aspect also makes them more environmentally friendly, reducing waste and minimizing the need for new materials. In conclusion, steel props offer numerous advantages over alternative support systems. Their exceptional load-bearing capacity, adjustability, durability, and reusability make them a popular choice in the construction industry. They provide a reliable and efficient support solution, ensuring safety and stability during construction or renovation projects.

- Q: How do steel props compare to concrete columns in terms of cost and efficiency?

- Steel props and concrete columns differ in terms of cost and efficiency. In terms of cost, steel props generally tend to be more expensive than concrete columns. This is primarily due to the fact that steel is a higher-priced material compared to concrete. Additionally, the manufacturing and installation processes for steel props can also be more complex and time-consuming, leading to higher labor costs. On the other hand, concrete columns are typically more cost-effective due to the abundance and low cost of concrete as a construction material. The simplicity of the manufacturing and installation processes for concrete columns also contributes to their lower overall cost. In terms of efficiency, steel props offer certain advantages. Steel is a stronger material compared to concrete, which means that steel props can support heavier loads and span longer distances. This makes them a preferred choice in construction projects where large spans or heavy loads need to be supported. Moreover, steel props are adjustable and reusable, allowing for flexibility in different construction scenarios. This adjustability and reusability can help save time and reduce costs in the long term. Concrete columns, on the other hand, have their own advantages in terms of efficiency. Concrete is a durable material that provides excellent fire resistance and can withstand extreme weather conditions. Concrete columns also have a longer lifespan compared to steel props, as they are not susceptible to corrosion or degradation over time. Additionally, the manufacturing and installation processes for concrete columns are generally simpler and quicker than those for steel props, resulting in faster construction timelines and increased efficiency. In summary, steel props and concrete columns have different cost and efficiency considerations. While steel props may be more expensive, they offer higher load-bearing capabilities, adjustability, and reusability. Concrete columns, on the other hand, are generally more cost-effective and provide long-lasting durability and simpler installation processes. The choice between the two will depend on the specific requirements and constraints of the construction project.

- Q: The exterior package aluminum plate, with steel support, about how much money.

- Of course, such as the height of 23 meters or three floors below, aluminum plate material is not very expensive, so this highly,The price of the package material is about 250-320 yuan / square meter

- Q: What are the different types of steel prop braces available?

- There are several different types of steel prop braces available, each designed for specific applications and requirements. 1. Adjustable Steel Props: These are the most common type of steel prop braces and are widely used in construction projects. They consist of a steel tube with an adjustable screw mechanism that allows for the height to be easily adjusted. This type of prop brace is versatile and can be used for a wide range of applications. 2. Push-Pull Props: Push-pull props, also known as shore props, are used to support horizontal loads in construction projects. They consist of two telescopic steel tubes with a threaded connection and are typically used to support formwork, scaffolding, and other temporary structures. One tube is pushed against the load, while the other is pulled to provide additional support. 3. Acrow Props: Acrow props are a type of adjustable steel prop brace that is commonly used in the construction industry. They are lightweight, easy to handle, and can be quickly adjusted to the desired height. Acrow props are typically used to support beams, walls, and other structures during construction or renovation projects. 4. Flying Props: Flying props, also known as flying shores, are used to support the upper floors of a building while the lower floors are being constructed. They consist of a steel prop brace that is attached to the lower floor and extends through openings in the upper floors. Flying props provide temporary support until the permanent structure is in place. 5. Heavy Duty Props: Heavy-duty props are designed for applications that require additional strength and load-bearing capacity. They are made from thicker and stronger steel tubes and are capable of supporting heavier loads. Heavy-duty props are commonly used in industrial projects, such as bridge construction or building renovation. 6. Tilt Props: Tilt props, also known as raker props, are used to provide horizontal support to walls or structures that are out of plumb. They consist of a vertical steel prop brace connected to a diagonal tube that is anchored to the ground or another structure. Tilt props help to stabilize leaning walls or structures during construction or renovation. It is important to select the appropriate type of steel prop brace based on the specific requirements of the project, including load-bearing capacity, adjustability, and structural stability. Consulting with a structural engineer or construction professional can help determine the most suitable steel prop brace for a particular application.

- Q: What is the typical lead time for ordering steel props?

- The typical lead time for ordering steel props can vary depending on various factors such as the supplier, quantity needed, and current market conditions. However, in general, it is common to expect a lead time of anywhere between a few days to a few weeks. If the supplier has the steel props in stock, the lead time can be as short as a few days, especially for smaller quantities. This is often the case for suppliers who maintain a large inventory and can quickly fulfill orders. On the other hand, if the steel props need to be manufactured or if the supplier does not have them readily available, the lead time can be longer. This is particularly true for larger quantities or custom orders. In such cases, the lead time can range from a couple of weeks to several weeks, depending on the complexity of the order and the production capacity of the supplier. It is important to note that lead times can also be influenced by external factors such as transportation delays, unforeseen circumstances, or seasonal fluctuations in demand. Therefore, it is advisable to check with the supplier or manufacturer directly to get an accurate estimate of the lead time for ordering steel props.

- Q: Can steel props be used in the construction of concert halls?

- Certainly, concert halls can make use of steel props in their construction. During the construction process, temporary support is often required for structures, and steel props serve this purpose quite commonly. Notably, these props can be adjusted and installed or removed with ease as needed. In the case of concert halls, they prove invaluable for bearing the weight of heavy equipment, stages, lighting rigs, and other elements that require support during construction. Furthermore, steel props are renowned for their strength and durability, making them perfect for meeting the load-bearing demands of a concert hall. However, it is crucial to ensure that the design and installation of steel props align with the specific requirements of the concert hall in order to guarantee safety and structural integrity.

- Q: What is the maximum lateral load that a steel prop can withstand?

- The maximum lateral load that a steel prop can withstand depends on various factors such as its dimensions, material strength, and design specifications. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to support temporary structures, formwork, and scaffolding. To determine the maximum lateral load capacity of a steel prop, one needs to consider its load-bearing capacity, which is typically specified by the manufacturer. These values can vary depending on the prop's size, grade of steel, and the specific design standards or regulations it adheres to. For example, a typical steel prop with a diameter of 48mm and a wall thickness of 3.2mm may have a maximum lateral load capacity ranging from 5 to 15 kilonewtons (kN), depending on the manufacturer and specific model. However, it is essential to consult the manufacturer's documentation or engineering specifications for precise load capacity information as this can vary between different brands and designs. Additionally, it is crucial to consider other factors that may affect the prop's lateral load capacity, such as its height, bracing, and the stability of the structure it supports. It is important to ensure that the prop is used within its specified load limits to prevent any potential failure or collapse of the temporary structure. To conclude, the maximum lateral load that a steel prop can withstand depends on its dimensions, material strength, and design specifications. Consulting the manufacturer's documentation or engineering specifications is essential to determine the precise load capacity of a specific steel prop.

Send your message to us

Adjustable Steel Props of Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords