Wedge Lock Scaffolding

Wedge Lock Scaffolding Related Searches

Scaffolding Roof Catwalk Scaffolding Scaffolding Access Scafolding Collapsible Scaffolding Scaffolding Props Scaffolding Wheels Advanced Scaffolding Scaffold Netting Modular Scaffolding Drywall Scaffolding Pipe And Clamp Scaffolding Scaffold Brackets Used Ring Lock Scaffolding For Sale Scaffolding Width Pipe Scaffolding Scaffolding Bars Best Scaffolding Scaffolding Canada Northern Tool Scaffolding Movable Scaffolding Platform Cuplock Scaffolding Load Capacity Cuplock Scaffolding Load Calculation H Type Scaffolding Baker Scaffold Wheels Scaffolding For Sale Winnipeg Pole Scaffolding For Sale Home Scaffolding For Sale Used Cuplock Scaffolding For Sale Scaffolding For Sale LowesWedge Lock Scaffolding Supplier & Manufacturer from China

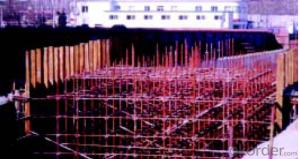

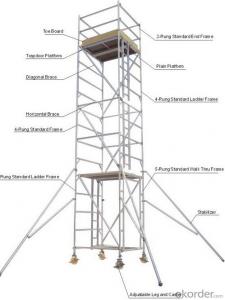

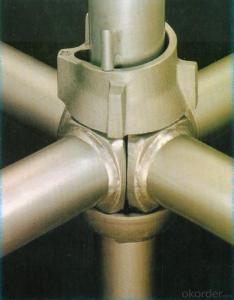

Wedge Lock Scaffolding is a versatile and robust temporary support structure used in various construction and maintenance projects. This type of scaffolding is known for its ease of assembly and high load-bearing capacity, making it a popular choice among professionals in the industry. The products included in Wedge Lock Scaffolding are uprights, ledgers, transoms, and diagonal braces, which together form a sturdy and reliable framework for workers to safely access elevated areas.The application and usage scenarios of Wedge Lock Scaffolding are extensive, ranging from residential construction to large-scale industrial projects. It is commonly used for tasks such as painting, window cleaning, and general maintenance, as well as more complex construction tasks that require a stable and secure platform. The modular design of Wedge Lock Scaffolding allows for easy customization and adaptation to different project requirements, making it a highly flexible solution for a wide range of applications.

Okorder.com is a wholesale supplier of Wedge Lock Scaffolding, offering a large inventory of high-quality products to meet the needs of various industries. As a reliable source for scaffolding materials, Okorder.com ensures that customers have access to the necessary components and accessories to assemble a safe and efficient scaffolding system. By providing a comprehensive range of Wedge Lock Scaffolding products, Okorder.com supports the success of construction and maintenance projects around the world.

Hot Products