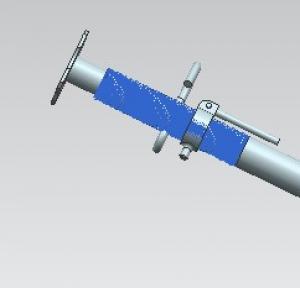

Painted Scaffolding Post Prop Support

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000根 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ProducGerman,Spanish,Middle East prop, steel pipe surpport.

Adjustable height:0.8-5.5m

Pipe/Tube tickness:1.5mm-4mm

Innner Diameter:40mm,48mm,etc.

Outer Diameter:48mm,56mm,60mm,etc.

Plate type:square,flower/clover,U-head

Nut type: single handle(common,7-style, big 7-style),Cup-style/Double handle

Pin type:line stright with metal cap,line straight without metal cap,chain,G-style

Plate size:120*12*4mm,120*120*5mm,140*140*5mm/5.5mm,etc.

Surface treatment: painted,galvanized,powder coating

Color:orange,red,blue,green,white,etc.

OEM ACCEPTABLE

Fast delivery wihtin 30days

Professional and reliable

We are specilized in various kinds of steel props, the goods are in high quality and reasonable price.In case you are interested in our products, please do not hesitate to contact me.

- Q: How do steel props contribute to worker safety?

- Steel props contribute to worker safety in several ways. Firstly, steel props provide a stable and reliable support system for construction workers. They are used to support temporary structures such as scaffolding, formwork, and falsework, ensuring that these structures remain stable and secure. This prevents any potential collapse or instability that could endanger the workers on site. Secondly, steel props are adjustable, allowing workers to easily modify the height and position of the support system as needed. This adjustability ensures that workers can work at a comfortable and safe height, reducing the risk of strains, falls, or other injuries that can occur when working on unstable surfaces. Moreover, steel props are designed to withstand heavy loads and adverse conditions. They are made from durable and strong materials, ensuring that they can handle the weight and pressure exerted by various construction activities. This enhances worker safety by minimizing the risk of accidents caused by structural failures or collapsing support systems. Steel props also provide a protective barrier for workers. They can be used to create safe zones or exclusion areas, preventing unauthorized access to hazardous areas of the construction site. By clearly defining these areas, workers are protected from potential hazards, such as falling debris or equipment, and unauthorized individuals are kept away from dangerous zones. Lastly, steel props are easy to install, dismantle, and transport. This not only saves time and effort for workers but also reduces the chances of accidents caused by improper handling or installation. Proper training and guidelines for using steel props further enhance worker safety by ensuring that they are used correctly and efficiently. Overall, steel props play a crucial role in ensuring worker safety on construction sites by providing stable support, adjustability, durability, protective barriers, and ease of use. They are an essential tool in preventing accidents, injuries, and fatalities in the construction industry.

- Q: Can steel props be used in different construction applications?

- Various construction applications can utilize steel props, which are also known as adjustable steel props or steel shores. These versatile support systems are commonly employed in construction to provide temporary support during projects involving beams, walls, and ceilings. Steel props can be adjusted in height to accommodate different construction needs. They can be employed to support formwork while concrete is poured, offer temporary support to walls or beams during demolition or renovation, or even serve as temporary supports for pre-existing structures during repair or reinforcement. The robustness and durability of steel props make them suitable for a wide range of construction applications. They possess the ability to withstand heavy loads and can be easily adjusted to the desired height, ensuring stability and safety at the construction site. Moreover, steel props offer several advantages, including ease of installation, reusability, and versatility. They can be installed, adjusted, and removed quickly and effortlessly, resulting in time and labor savings. Additionally, their reusability makes them a cost-effective solution for multiple construction projects. In conclusion, steel props are indeed applicable to diverse construction scenarios due to their adjustable height, strength, durability, and versatility. They play a crucial role in providing temporary support and stability during construction or renovation projects, making them an indispensable tool for professionals in the construction industry.

- Q: What are the potential hazards associated with using steel props?

- Some potential hazards associated with using steel props include the risk of structural failure or collapse, especially if the props are not properly installed or if they are overloaded. There is also a risk of injury from falling objects or debris if the props are not secured correctly. Additionally, improper handling or positioning of the props can lead to musculoskeletal injuries for workers. It is important to follow safety guidelines and conduct regular inspections to mitigate these hazards.

- Q: Can steel props be used to support beams and columns?

- Yes, steel props can be used to support beams and columns. Steel props, also known as scaffolding props or shoring props, are temporary structural devices commonly used in construction to support loads during the construction or renovation of buildings, bridges, or other structures. They are adjustable in height and can be easily installed and removed as needed. Steel props are typically made of high-strength steel, providing the necessary load-bearing capacity to support beams and columns safely. They are commonly used to provide temporary support during the construction of concrete beams and columns, ensuring stability and preventing any structural failure. Steel props are a versatile and reliable solution for providing temporary support to beams and columns during construction projects.

- Q: Can steel props be used for supporting temporary concert stages or platforms?

- Indeed, for the purpose of supporting temporary concert stages or platforms, steel props prove to be a suitable option. Referred to as adjustable props or acrow props, these props are commonly utilized in construction and temporary structures in order to furnish support and stability. They are designed with the capacity to bear heavy loads and can be conveniently adjusted to attain the desired height. When it comes to the task of supporting temporary concert stages or platforms, steel props emerge as an ideal selection. One can position them strategically underneath the stage or platform to distribute weight evenly, guaranteeing stability. Moreover, their adjustable nature permits precise leveling and customization to accommodate varying stage heights or irregular ground surfaces. Steel props are manufactured from high-quality steel and are engineered to endure substantial loads, rendering them reliable and robust. Additionally, they are effortless to install and dismantle, a crucial feature for temporary structures such as concert stages or platforms that necessitate prompt setup and teardown. In conclusion, steel props offer the essential support and stability that temporary concert stages or platforms require. They represent a dependable and pragmatic solution for ensuring the safety and durability of such structures.

- Q: Can steel props be used for supporting temporary bridges during emergencies?

- Indeed, steel props have the capability to support temporary bridges in emergency scenarios. Their robustness and longevity make them an ideal option for offering provisional assistance to bridges during critical situations. They possess the ability to effectively bear the bridge's weight and guarantee its stability until a permanent resolution can be implemented. Furthermore, steel props are adjustable, facilitating effortless installation and customization to meet the specific demands of the bridge. Moreover, steel props are readily accessible and extensively utilized in construction, rendering them a pragmatic selection for emergency bridge support.

- Q: Do steel props require any maintenance?

- Regular maintenance is necessary for steel props to ensure they function properly and remain safe. Maintenance tasks for steel props may include the following: 1. Clean the steel props regularly by using a brush, water, and mild detergent to remove dirt, debris, or any substances that could affect their performance. 2. Inspect the steel props on a regular basis to check for signs of damage such as cracks, dents, or corrosion. Any damaged props should be immediately replaced. 3. Apply lubrication to movable parts of the steel props, such as adjustable screws or pins, to prevent them from seizing or becoming stiff. This will ensure easy and smooth adjustment when necessary. 4. Store the steel props properly when not in use to prevent rust or damage. This may involve keeping them in a dry and well-ventilated area, away from moisture or chemicals that could cause corrosion. 5. Periodically test the steel props to ensure they can bear the specified load capacity. This can be done using load testing equipment or by following the manufacturer's guidelines. Following the manufacturer's instructions and guidelines for maintenance is crucial to ensure the longevity and safe usage of steel props. Regular maintenance and inspection also help in identifying potential issues early on, reducing the risk of accidents or failures during use.

- Q: Do steel props require any special tools for installation and adjustment?

- Special tools are typically required for the installation and adjustment of steel props. These tools are necessary to ensure proper installation and adjustment of the props, as well as to maintain their stability and safety. Common tools used for steel prop installation and adjustment include: 1. A prop wrench is a specialized tool that is used to tighten and loosen the prop nuts. Its design provides a secure grip and facilitates the adjustment process. 2. To check the verticality and alignment of the props, a spirit level is used. It assists in ensuring that the props are properly adjusted and offer the necessary support. 3. A hammer is necessary to drive the props into the ground or other supporting surfaces. It ensures that the props are firmly secured and provide stability. 4. For tightening and loosening the bolts and nuts of the props, a spanner is used. It is crucial to use the correct size of spanner to avoid damaging the props. 5. Certain components of the props may need adjustment, such as tightening or loosening the locking mechanism. In such cases, a screwdriver may be required. 6. A measuring tape is used to determine the height and distance requirements for the props. It helps in ensuring accurate installation and adjustment. Using the appropriate tools and following the manufacturer's instructions is crucial when installing and adjusting steel props. This ensures the maintenance of their structural integrity and guarantees their safe and effective use.

- Q: What are the typical applications for steel props?

- Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and renovation projects. They are typically used to support temporary structures, such as scaffolding, formwork, or falsework, and provide stability and safety during the construction process. Steel props are adjustable in height and can be easily secured in place, making them ideal for various applications such as supporting beams, slabs, walls, or ceilings. They are widely used in residential, commercial, and industrial projects to ensure the structural integrity and safety of temporary structures.

- Q: How do you prevent accidents or injuries while using steel props?

- To prevent accidents or injuries while using steel props, there are several important measures that should be followed: 1. Training and knowledge: It is crucial to be properly trained in the use of steel props before handling them. Familiarize yourself with the manufacturer's instructions, safety guidelines, and any specific precautions that need to be taken. 2. Regular inspections: Before using steel props, thoroughly inspect them for any signs of damage, such as cracks, bends, or excessive wear. If any issues are found, they should be repaired or replaced immediately to ensure their effectiveness and safety. 3. Proper handling and storage: When handling steel props, it is important to use proper lifting techniques and avoid overloading them beyond their specified capacity. Additionally, they should be stored in a safe and secure manner, away from areas where they can be accidentally knocked over or damaged. 4. Secure placement: Ensure that steel props are properly positioned and securely anchored to prevent them from shifting or collapsing during use. Follow the manufacturer's guidelines for proper placement and ensure that the supporting surface is stable and able to bear the load. 5. Clear communication and coordination: If multiple workers are involved in using steel props, clear communication and coordination are essential. Establish a system of signals or verbal communication to ensure that everyone is aware of the activities being performed and can take necessary precautions. 6. Personal protective equipment (PPE): Always wear the necessary personal protective equipment, such as safety gloves, goggles, and steel-toed boots, while handling steel props. This will help protect against potential accidents or injuries that may occur due to sharp edges, falling debris, or other hazards. 7. Regular maintenance: Steel props should be regularly maintained, including cleaning, lubrication, and inspection, to ensure their optimal performance and longevity. Any damaged or worn-out parts should be replaced promptly. 8. Risk assessment: Conduct a thorough risk assessment before using steel props to identify potential hazards and implement appropriate control measures. This may involve considering factors such as the load being supported, environmental conditions, and the presence of other workers or equipment in the vicinity. By following these preventative measures, individuals can greatly reduce the risk of accidents or injuries while using steel props, ensuring a safer working environment for all involved.

Send your message to us

Painted Scaffolding Post Prop Support

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000根 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords