Boat Prop Lock

Boat Prop Lock Related Searches

Boat Prop Guard Boat Propeller Cover High Performance Boat Props Acme Boat Propellers Ship Propeler Old Boat Anchors Inboard Boat Propeller Calculator Double Hook Mortise Lock Chain Anchor For Drift Boat Outboard Propeller Repair Anchor Of A Ship 4 Blade Prop Blade Boat Pontoon Boat Anchor Storage Retractable Deck Roof Best Prop For Speed Peri Push Pull Props Rmd Push Pull Props Waterproof Seal Replacement Window Sash Locks Hydraulic Hose Rack Waterproof Membrane For Decks Deck Slab Self Propelled Scissor Lift Backer Board Waterproof Industrial Door Handles And Locks Waterproofing Wet Areas Damp Proof Membrane Waterproof Sealer Shisham PropsBoat Prop Lock Supplier & Manufacturer from China

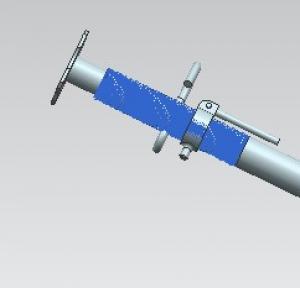

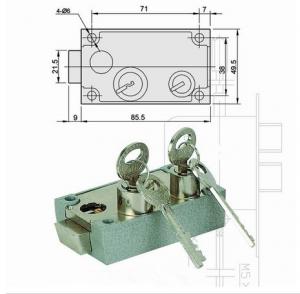

Boat Prop Lock is a specialized security device designed to protect boat propellers from theft and unauthorized use. It is an essential accessory for boat owners who want to ensure the safety and security of their vessel's propulsion system. This product is engineered to be robust and durable, providing a reliable barrier against potential threats.The Boat Prop Lock is widely used in various marine environments, including marinas, boatyards, and private docks. It serves as a deterrent for thieves who may attempt to steal or tamper with the boat's propeller. By using this product, boat owners can have peace of mind knowing that their investment is protected from potential damage or loss. The Boat Prop Lock can be easily installed and removed, making it a convenient solution for those who need to access their propellers regularly.

Okorder.com is a reputable wholesale supplier of the Boat Prop Lock, offering a vast inventory to meet the demands of customers worldwide. As a leading online platform, Okorder.com is committed to providing high-quality products at competitive prices, ensuring that customers receive the best value for their money. With a comprehensive range of Boat Prop Lock options available, Okorder.com is the go-to destination for those seeking to secure their boat propellers effectively.

Hot Products