Germany standard D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

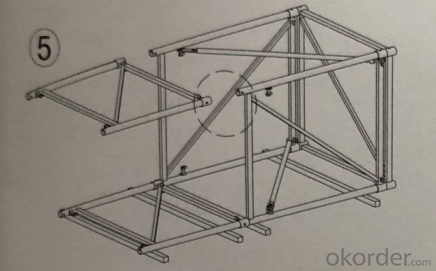

Fast & user-friendly, high load bearing towers for all shoring heights

High Load Bearing Towers for All Shoring Heights

• Using only 6 basic components any shoring height can be reached

• Each tower can take loads of up to 200kN making it an ideal shoring solution for all standard applications

• High load-bearing tower with minimum footprint of only 1m x 1m for increased workspace

• Efficient & Safe assembly following only a few basic steps

• Tower arrangements can be optimized by using the high load bearing capacities

Newly Introduced Rosettes for Increased Adaptability

• The Integrated Rosette Ring offers a wide range of possibilities for any job site

• With 8 new connection slots, the D-15 Tower now has 360 degrees of flexibility

• D-15 Towers can now be combined & connected with Modular scaffolding solution to achieve complex geometries in any structure

An Excellent investment for any Contractor

• All-rounded hot dip galvanisation guarantees a service life of over 10 years with minimum care and maintenance

• Few components decreases the chances of loss of material on a job site reducing part replacement costs

• The D-15 shoring can be utilized in various types of structures such as high-rises, water towers, silos etc. where high load concentration is required

• Efficient stacking of the towers reduces the amount of stocking area to store the system

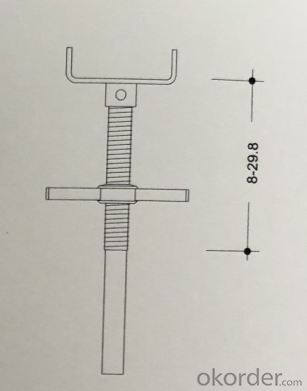

Head Jack 38/52

For bearing timber or steel beams. Slope of up to 6% can be compensated by the head plate.

Height adjustment: from 8 cm to 29.8 cm.

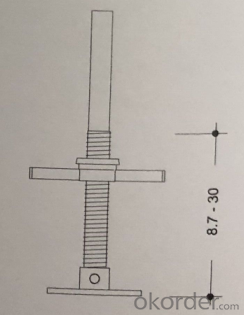

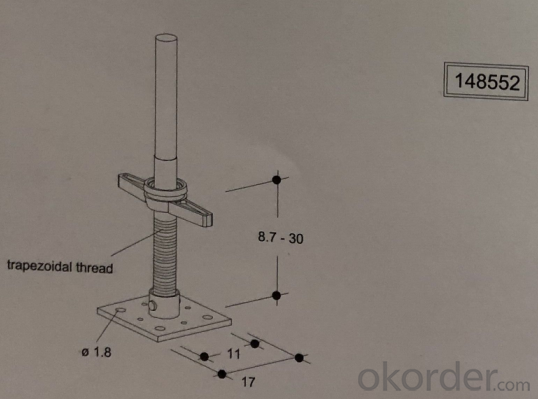

Base Jack 38/52

For setting-up the frame support. Slope of up to 6 % can be compensated by the head plate.

Height adjustment: from 8.7 cm to 30.0 cm

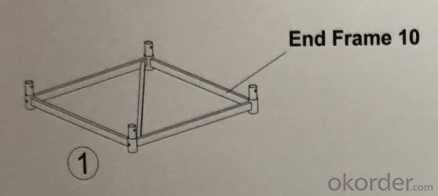

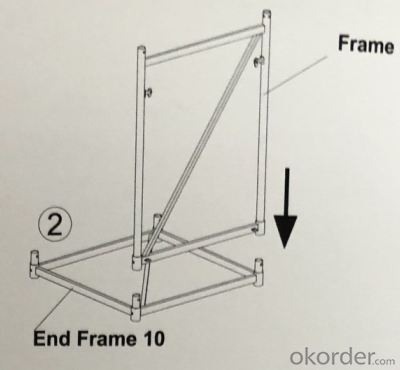

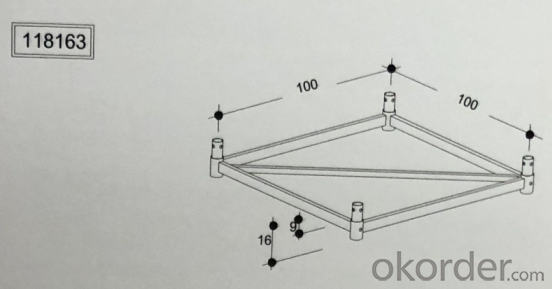

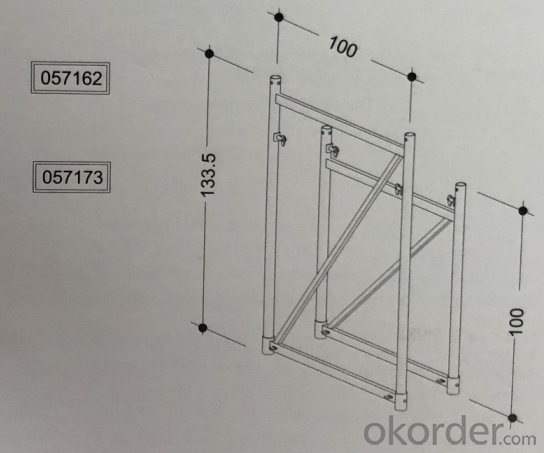

End Frame 10

To be assembled as sectional bracing of the frame support to ensure the square shape.

Always installed at the top and at the base.

Installation height at the top: 225px

installation height at the base: 400px

Frame 100

The frame are tension-resistantly connction with the tightly built-in wedges (quick- action connectors.)

Pins with gravity flips are provided for attaching the diagonals.

Design height of frame: 100 cm or 133.5 cm.

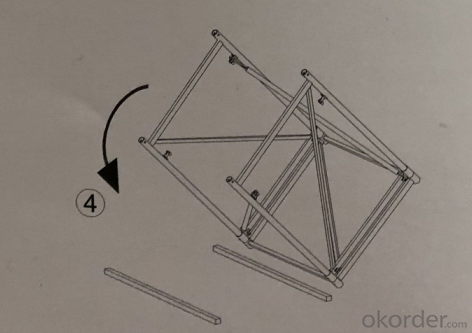

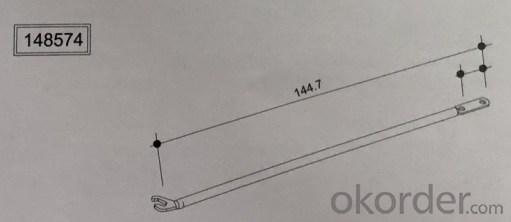

Diagonal

Used for bracing both types of frame within the tower at right angles to frame plane.

The lower end with its claws is fixed to the horizonal bottom bar of one frame, the upper end fixed to the hinged pin of the opposite frame.

- Q: Can steel props be used in tunnel construction?

- Indeed, tunnel construction can make effective use of steel props. These props are extensively employed in a diverse range of construction endeavors, including tunnel construction, to furnish provisional reinforcement to excavated regions. Their adjustability allows for easy installation, and they offer steadfast support to the tunnel walls and roof throughout construction. Manufactured to endure tremendous loads, these props guarantee the stability and security of the tunnel structure. The benefits of steel props are manifold, encompassing remarkable load-bearing capacity, effortless installation, and adaptability in adjusting both height and length. Consequently, they represent a fitting selection for tunnel construction ventures necessitating temporary support.

- Q: Can steel props be used in supporting temporary bridges and walkways?

- Yes, steel props can be used effectively in supporting temporary bridges and walkways. Steel props, also known as adjustable steel props or acrow props, are strong and sturdy support systems that can withstand heavy loads. They are commonly used in construction and temporary structures to provide reliable support and stability. As temporary bridges and walkways require stable and secure footing, steel props are an ideal choice for ensuring the safety and integrity of these structures.

- Q: How do steel props compare to hydraulic jacks?

- Steel props and hydraulic jacks are both commonly used for temporary support in construction projects, but they have some key differences. Steel props are typically made of strong steel tubes and are manually adjusted to provide support. They are easy to install and can be adjusted to the desired height. However, they may require more labor and time to set up and adjust. On the other hand, hydraulic jacks are powered by hydraulic pressure, making them easier and quicker to set up and adjust. They also have a higher load-bearing capacity compared to steel props. However, hydraulic jacks are generally more expensive and require skilled operators. Overall, the choice between steel props and hydraulic jacks depends on the specific requirements of the project, the load-bearing capacity needed, and the available budget and resources.

- Q: Are steel props suitable for supporting temporary stages or platforms with moving parts?

- No, steel props may not be suitable for supporting temporary stages or platforms with moving parts. Steel props are typically used for providing vertical support and stability to structures like buildings or scaffolding. However, when it comes to stages or platforms with moving parts, such as those used in theatrical productions or concerts, more specialized and flexible support systems are usually required to accommodate the dynamic nature of these setups.

- Q: What are the different load classes available for steel props?

- The different load classes available for steel props are typically categorized as light-duty, medium-duty, and heavy-duty. Light-duty props are designed to support lower loads and are suitable for residential or light commercial projects. Medium-duty props can handle higher loads and are commonly used in commercial construction. Heavy-duty props are the strongest and can support extremely heavy loads, making them ideal for industrial or heavy construction projects.

- Q: What are the different weight capacities of steel props?

- The weight capacities of steel props can vary depending on their size and specifications. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction and temporary support applications to provide vertical support and stability to structures or formwork systems. The weight capacity of steel props typically depends on their load-bearing capabilities, which are determined by factors such as the prop's height, diameter, and material strength. In general, steel props are designed to support heavy loads and can have weight capacities ranging from a few hundred kilograms to several tons. Smaller steel props, such as those with a height of around 1-2 meters and a diameter of 40-50mm, usually have weight capacities of up to 2-3 tons. These props are commonly used for lighter support applications, such as supporting beams or formwork for slabs and walls. Medium-sized steel props, with heights ranging from 2-4 meters and diameters around 50-60mm, can typically handle weight capacities of around 3-5 tons. These props are often used for supporting heavier loads, such as larger beams or formwork systems for multi-story structures. Larger steel props, which can have heights exceeding 4 meters and diameters of 60mm or more, are capable of supporting even heavier loads. These props can have weight capacities of 5-10 tons or more, depending on their specific design and material strength. They are commonly used for supporting heavy beams, columns, or other structural elements during construction or renovation projects. It's important to note that the weight capacity of steel props may also be influenced by other factors, such as the condition of the ground or the type of load being supported. Therefore, it is crucial to consult the manufacturer's specifications or seek professional advice to ensure the proper selection and use of steel props for a specific application.

- Q: Are steel props suitable for supporting temporary grandstands?

- Yes, steel props are suitable for supporting temporary grandstands. Steel props are known for their strength and durability, making them an ideal choice for supporting heavy structures like grandstands. They can provide the necessary stability and load-bearing capacity required to ensure the safety of the temporary seating arrangement. Moreover, steel props can be easily adjusted and secured in place, allowing for flexibility in positioning and ensuring that the grandstands are level and secure. Overall, steel props are a reliable and effective option for supporting temporary grandstands.

- Q: Are steel props reusable?

- Yes, steel props are reusable. They are designed to be durable and can be used multiple times for supporting structures during construction or renovation projects.

- Q: Are steel props suitable for use in underground utility tunnel construction?

- Indeed, underground utility tunnel construction can benefit from the use of steel props. These props, alternatively referred to as steel shoring or steel supports, are commonly employed in construction projects to provide temporary support to structures or excavations. They possess the ability to withstand heavy loads and ensure stability across a range of applications, including underground tunnels. There are numerous advantages to utilizing steel props in underground utility tunnel construction. Firstly, they exhibit strength and durability, enabling them to bear the weight of the tunnel as well as any additional loads such as utilities or equipment. Their adjustable nature allows for flexibility throughout the construction process, accommodating different heights and lengths as needed. Furthermore, steel props are characterized by their ease of installation and removal, rendering them ideal for temporary applications. They can be swiftly assembled and disassembled, contributing to a reduction in construction time and costs. Additionally, steel props can be repurposed in other projects, making them a cost-effective long-term solution. In terms of safety, steel props provide a stable and secure support system for workers and equipment during tunnel construction. They are specifically designed to endure lateral forces and mitigate the risk of collapse or accidents. This prioritizes the safety of workers while also safeguarding the tunnel and utilities against potential damage. In summary, steel props prove to be a fitting choice for underground utility tunnel construction. They offer strength, durability, flexibility, and safety, making them an effective solution for supporting the excavation and construction of tunnels.

- Q: Can steel props be used for shoring purposes?

- Yes, steel props can be used for shoring purposes. Steel props, also known as adjustable steel props or acrow props, are commonly used in construction to provide temporary support to structures, walls, or ceilings during renovation, repair, or construction work. These props can be easily adjusted to the required height and provide a stable and secure support system.

Send your message to us

Germany standard D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords