GHI D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

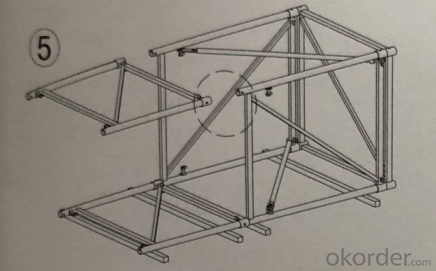

Fast & user-friendly, high load bearing towers for all shoring heights

High Load Bearing Towers for All Shoring Heights

• Using only 6 basic components any shoring height can be reached

• Each tower can take loads of up to 200kN making it an ideal shoring solution for all standard applications

• High load-bearing tower with minimum footprint of only 1m x 1m for increased workspace

• Efficient & Safe assembly following only a few basic steps

• Tower arrangements can be optimized by using the high load bearing capacities

Newly Introduced Rosettes for Increased Adaptability

• The Integrated Rosette Ring offers a wide range of possibilities for any job site

• With 8 new connection slots, the D-15 Tower now has 360 degrees of flexibility

• D-15 Towers can now be combined & connected with Modular scaffolding solution to achieve complex geometries in any structure

An Excellent investment for any Contractor

• All-rounded hot dip galvanisation guarantees a service life of over 10 years with minimum care and maintenance

• Few components decreases the chances of loss of material on a job site reducing part replacement costs

• The D-15 shoring can be utilized in various types of structures such as high-rises, water towers, silos etc. where high load concentration is required

• Efficient stacking of the towers reduces the amount of stocking area to store the system

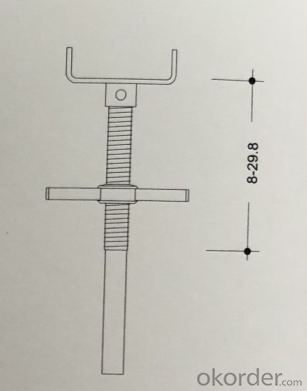

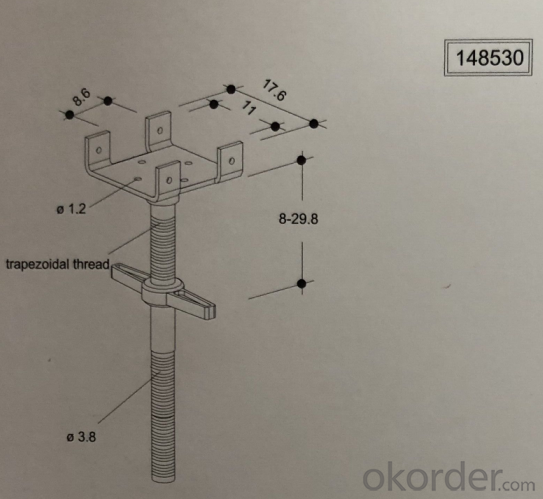

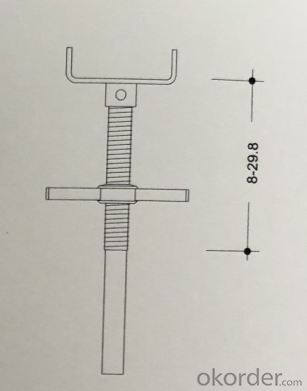

Head Jack 38/52

For bearing timber or steel beams. Slope of up to 6% can be compensated by the head plate.

Height adjustment: from 8 cm to 29.8 cm.

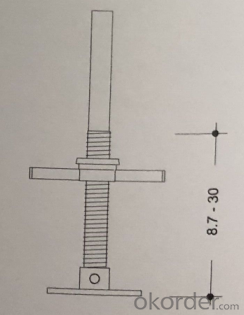

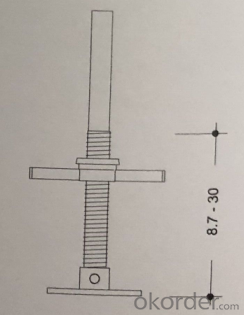

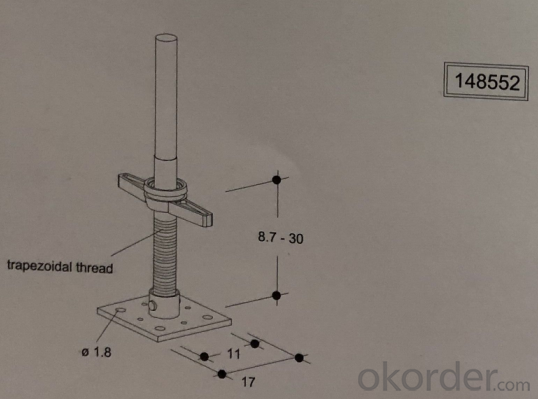

Base Jack 38/52

For setting-up the frame support. Slope of up to 6 % can be compensated by the head plate.

Height adjustment: from 8.7 cm to 30.0 cm

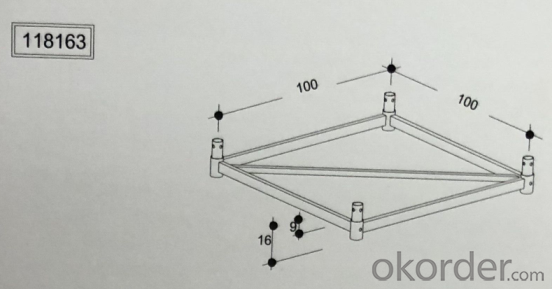

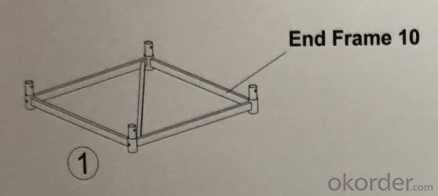

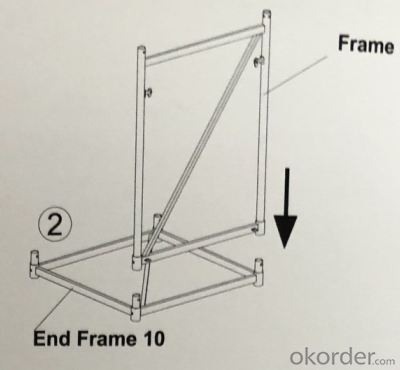

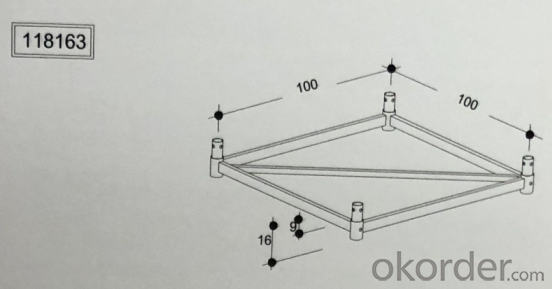

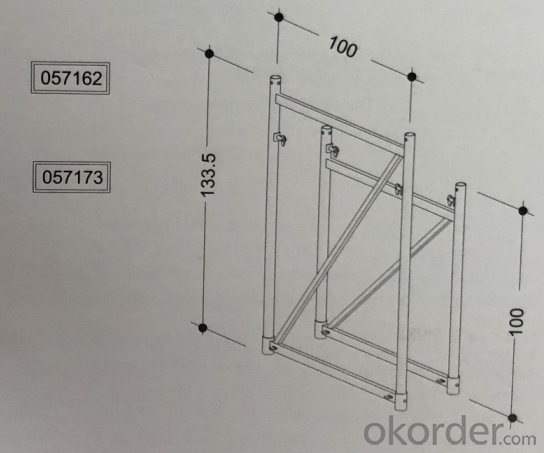

End Frame 10

To be assembled as sectional bracing of the frame support to ensure the square shape.

Always installed at the top and at the base.

Installation height at the top: 225px

installation height at the base: 400px

Frame 100

The frame are tension-resistantly connction with the tightly built-in wedges (quick- action connectors.)

Pins with gravity flips are provided for attaching the diagonals.

Design height of frame: 100 cm or 133.5 cm.

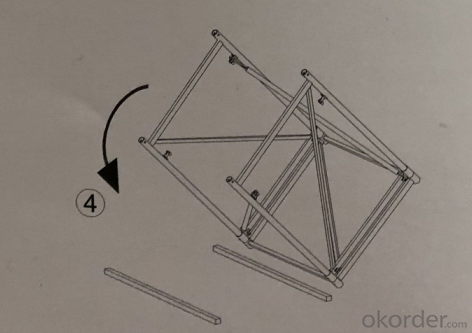

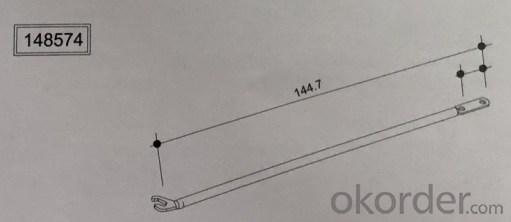

Diagonal

Used for bracing both types of frame within the tower at right angles to frame plane.

The lower end with its claws is fixed to the horizonal bottom bar of one frame, the upper end fixed to the hinged pin of the opposite frame.

- Q: Can steel props be used for temporary support during silo construction?

- Yes, steel props can be used for temporary support during silo construction. Steel props are commonly used in construction projects to provide temporary support and stability to structures. They are adjustable, sturdy, and can handle heavy loads, making them suitable for supporting the weight of a silo during its construction process.

- Q: Are steel props suitable for supporting floor slabs?

- Floor slabs can be effectively supported by steel props. These props, also known as adjustable steel props or acrow props, are commonly utilized in construction for temporary support of horizontal structures like floor slabs. They possess the ability to adjust their height, making them adaptable to various slab thicknesses and load requirements. The composition of steel props consists of a steel tube with an inner screw mechanism, enabling easy and precise adjustment of height. They are specifically designed to withstand heavy loads, ensuring stability and support throughout construction activities. The outer tube is constructed with strong steel material, while the inner screw mechanism is typically made of hardened steel, guaranteeing durability and reliability. One significant advantage of using steel props for floor slab support is their impressive load-bearing capacity. These props have the capability to bear substantial loads, making them suitable for a wide range of construction projects. Furthermore, their adjustable height feature provides flexibility in supporting slabs with varying thicknesses. In addition, steel props are user-friendly when it comes to installation and dismantling, saving time and effort during construction. They can be swiftly adjusted to the desired height and securely positioned. Furthermore, they are reusable, making them a cost-effective solution for supporting floor slabs in multiple projects. In conclusion, steel props possess the necessary qualities to support floor slabs effectively. Their load-bearing capacity, adjustable height feature, durability, and ease of installation make them a reliable and versatile option for temporary support during construction activities.

- Q: How do steel props affect the construction schedule?

- Steel props, also known as steel shoring or steel supports, play a crucial role in the construction process and can significantly impact the construction schedule. These props are temporary structural elements used to support loads during construction or renovation projects. One of the primary ways that steel props affect the construction schedule is by providing stability and support to the structure. This allows workers to safely carry out various tasks, such as pouring concrete, installing beams, or performing demolition work. Without steel props, construction activities may be delayed or even halted due to safety concerns. Moreover, steel props enable construction projects to progress smoothly by providing additional support to the structure during critical stages. For example, when constructing tall buildings or structures with large spans, steel props can be used to support the weight of the structure until permanent supports, such as columns or beams, are installed. This allows construction to continue without delays, as it eliminates the need to wait for the completion of permanent structural elements. Additionally, steel props can also facilitate faster construction by providing a means of supporting formwork or falsework. Formwork is used to create the desired shape and structure of concrete elements, such as walls or slabs. Steel props can hold the formwork in place while the concrete cures, allowing for quicker removal and repositioning of formwork for subsequent stages. This accelerates the construction process and reduces the overall project duration. However, it is important to note that the impact of steel props on the construction schedule can be influenced by various factors. These include the number and size of props required, their positioning, and the complexity of the construction project. In some cases, delays may occur if adjustments or modifications need to be made to the props due to changes in design or unforeseen circumstances. In conclusion, steel props have a significant impact on the construction schedule by providing stability, support, and acceleration to the construction process. Their use ensures the safety of workers, enables the progression of critical stages, and allows for faster completion of construction projects.

- Q: How do you inspect and certify steel props for safe use?

- To inspect and certify steel props for safe use, a thorough examination is conducted by trained professionals. This involves checking for any visible damage, such as bends, cracks, or deformities in the prop. Additionally, measurements are taken to verify its dimensions and ensure it meets the required specifications. Load testing may also be conducted to assess its load-bearing capacity. Once the inspection is complete and the prop meets all safety standards, it can be certified for safe use.

- Q: Are steel props resistant to corrosion?

- Yes, steel props are generally resistant to corrosion due to their protective coating and high durability. However, their resistance to corrosion can vary depending on the specific steel composition and the environmental conditions they are exposed to.

- Q: How do you ensure stability when using steel props on uneven surfaces?

- To ensure stability when using steel props on uneven surfaces, it is important to follow these steps: 1. Start by ensuring that the steel props are properly adjusted to the correct height for the specific area or surface. 2. Use a spirit level or a similar tool to check the levelness of the steel props. Adjust the props accordingly to ensure they are perpendicular to the ground. 3. If the surface is extremely uneven or unstable, consider using additional supports such as wooden boards or wedges to provide extra stability and distribute the weight evenly. 4. Regularly inspect the steel props and the surrounding area to identify any signs of movement or instability. If any issues are detected, make necessary adjustments or reinforce the supports as needed. 5. Finally, it is crucial to follow the manufacturer's guidelines and safety instructions while using steel props to ensure stability and prevent any accidents or injuries.

- Q: How do you properly set up a steel prop?

- To properly set up a steel prop, start by assessing the weight and load requirements of the structure you need to support. Choose a steel prop with the appropriate load capacity and length. Next, ensure the ground is level and compacted to provide a stable base. Position the steel prop vertically beneath the desired support point, adjusting the length as needed. Use a spirit level to ensure the prop is perfectly vertical. Finally, tighten the prop's adjustable mechanism securely to ensure it can safely bear the load.

- Q: Can steel props be used in supporting temporary retaining walls?

- Yes, steel props can be used to support temporary retaining walls. Steel props are strong and durable, making them suitable for providing the necessary support and stability required for temporary retaining walls.

- Q: What are the recommended storage conditions for steel props?

- The recommended storage conditions for steel props include keeping them in a dry and well-ventilated area to prevent moisture buildup, which can lead to corrosion. It is important to store the props away from direct sunlight to avoid any potential damage from UV rays. Additionally, it is recommended to stack the props horizontally to prevent deformation or bending. Regular inspection and maintenance should be conducted to ensure the props are in good condition and any signs of rust or damage should be addressed promptly.

- Q: Do steel props have any adjustable base plates for uneven surfaces?

- Yes, steel props often have adjustable base plates that can be adapted to accommodate uneven surfaces. These adjustable base plates are designed to provide stability and ensure the prop remains level and secure, even on irregular terrain.

Send your message to us

GHI D15 formwork shoring system steel prop

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords