Climbing Formwork- Formwork- Cantilever

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

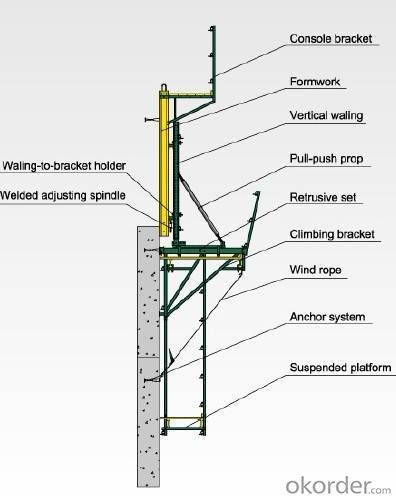

CantileverFormwork is mainly used in the concrete pouring of pier,high buildings, and so on. The concrete lateral pressure is entirely supportedby anchor system and the wall-through tie-rods, additional reinforcement is notneeded. The construction is easy, rapid and economical. A single pouring height is high and thefinished concrete surface is perfect. Cantilever formwork has several types,thestructure is similar, and has its own different characteristic.Canuse them according to actual demand.

Maincantilever Formwork:PJ200 & PJ240,CB-240 etc.

Anchor system

Anchor system is the most importantsupporting part. The system is made of five parts shown below. There into,tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusingafter the concrete pouring

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

- Q: Can steel props be used for supporting temporary mining structures?

- Yes, steel props can be used for supporting temporary mining structures. Steel props are commonly used in the construction industry to provide temporary support to structures during construction or renovation work. They are designed to bear heavy loads and provide stability, making them suitable for supporting temporary mining structures such as tunnels, mine shafts, or underground chambers. Steel props are adjustable and can be easily extended or contracted to fit the required height or length. This adaptability allows them to be used in various mining applications where different support requirements exist. Additionally, steel props are durable and resistant to corrosion, which is essential in mining environments that often involve exposure to moisture, chemicals, and other harsh conditions. Moreover, steel props can be combined with other support systems, such as timber or concrete, to enhance their load-bearing capacity and overall stability. This flexibility allows for the customization of support systems based on the specific needs of the mining project. However, it is important to note that the selection of support systems for temporary mining structures should be based on a thorough engineering assessment and compliance with relevant safety regulations. Professional expertise and consultation should be sought to ensure the appropriate design, installation, and maintenance of steel props or any other support systems used in mining operations.

- Q: How do you check the stability and integrity of a steel prop?

- To check the stability and integrity of a steel prop, several steps can be followed. Firstly, conduct a visual inspection to look for any signs of damage, such as cracks, dents, or deformities. Secondly, ensure that all connections and fasteners are secure and not loose. Thirdly, use a level to check if the prop is plumb and not leaning. Additionally, verify that the prop is properly braced and supported, ensuring it has adequate load-bearing capacity. Finally, conduct load testing if necessary, applying incremental weight to assess the prop's stability.

- Q: Are steel props adjustable in both vertical and diagonal directions?

- Yes, steel props are adjustable in both vertical and diagonal directions. Steel props, also known as adjustable steel acrow props, are widely used in construction and temporary support applications. These props consist of a steel tube with an inner and outer tube, which can be adjusted to the desired height by rotating the inner tube. The props also have a threaded collar that enables fine adjustments for vertical alignment. In addition to vertical adjustments, steel props can also be adjusted diagonally. This is achieved by using a threaded pin or bolt at the top of the prop, which allows for angular adjustments. By loosening the pin or bolt, the prop can be tilted or adjusted to the desired diagonal position. Once the required angle is achieved, the pin or bolt is tightened to secure the prop in place. The ability to adjust steel props in both vertical and diagonal directions makes them versatile and suitable for various construction and support applications. They provide stability and support by ensuring accurate alignment and weight distribution, making them an essential tool in the construction industry.

- Q: Can steel props be customized for specific project requirements?

- Yes, it is possible to customize steel props to meet the specific requirements of a project. Steel props, also known as adjustable steel props or steel support props, are commonly used in construction projects to provide temporary support to structures or existing structures. They are versatile and can be adjusted to different heights. Steel props can be customized in various ways to suit the project's needs. Firstly, they can be manufactured in different sizes and load capacities to support different types of structures and loads. This ensures that the props are strong enough to withstand the weight and pressures they will experience during the construction process. Secondly, additional features can be added to steel props to enhance their functionality. For example, adjustable heads can be designed to provide flexibility in supporting different angles or surfaces. They can also be equipped with leveling mechanisms, such as threaded screws or hydraulic systems, to ensure precise and stable support on uneven or sloping surfaces. Moreover, specific surface finishes or coatings can be applied to steel props to improve their durability and longevity. Galvanization or powder coating can be used to protect them from corrosion or rust, making them suitable for outdoor or harsh environments. Additionally, the length of steel props can be adjusted according to the specific height requirements of the project. This allows for a precise fit and ensures that the props offer adequate support without being too short or too long. To summarize, steel props can be customized in terms of size, load capacity, additional features, surface finish, and length to meet the specific requirements of a project. This customization ensures that the props are suitable for their intended purpose, providing effective support and contributing to the successful completion of the project.

- Q: Can steel props be used in conjunction with scaffolding systems?

- Yes, steel props can be used in conjunction with scaffolding systems. Steel props are adjustable vertical supports that can provide additional stability and support to scaffolding structures. They are commonly used to provide extra strength and load-bearing capacity to scaffolding systems, especially when working on heavy-duty construction projects or when additional support is required for specific areas.

- Q: Are steel props commonly used in industrial construction projects?

- Yes, steel props are commonly used in industrial construction projects. Steel props, also known as adjustable steel props or steel acrow props, are temporary support structures that are used to provide stability to construction areas during the building process. They are typically made of high-quality steel and can be adjusted to different heights, allowing them to be used in various construction scenarios. Steel props are commonly used in industrial construction projects because of their strength, durability, and flexibility. They provide support to structures such as walls, ceilings, and beams, ensuring their stability and safety. Additionally, steel props are relatively easy to install and dismantle, making them a popular choice in construction projects where speed and efficiency are crucial. Overall, steel props play a vital role in industrial construction projects, providing the necessary support and stability required during the construction process.

- Q: Can steel props be used for supporting temporary staircases or ramps?

- Temporary staircases or ramps can be supported using steel props. Commonly referred to as adjustable props, steel props are frequently utilized in construction projects to provide temporary support and stability to structures. They are specifically designed to be easily adjustable in height, making them highly suitable for supporting a wide range of temporary structures, including staircases and ramps. Constructed from durable materials like steel tubes and plates, steel props are capable of withstanding heavy loads and offering reliable support. Furthermore, they can be effortlessly installed and dismantled, making them extremely convenient for temporary construction requirements. In conclusion, steel props are a fitting choice for supporting temporary staircases or ramps due to their strength, adjustability, and user-friendly nature.

- Q: What are the potential drawbacks of using steel props?

- There are several potential drawbacks associated with using steel props in construction projects. 1. Weight and transportation: Steel props can be heavy and bulky, making them difficult to transport and handle on construction sites. This can increase the labor and time required for their installation and removal. 2. Limited adjustability: Although steel props are adjustable in length, they have a limited range of adjustment. This can pose challenges when dealing with uneven ground or varying heights in different areas of the construction site. 3. Corrosion and maintenance: Steel props are susceptible to corrosion when exposed to moisture or harsh environments. Regular maintenance and inspection are necessary to prevent rust and ensure their structural integrity. Failure to address corrosion can lead to weakened props and potential safety hazards. 4. Cost: Steel props can be more expensive compared to other temporary support systems. The initial investment for purchasing or renting steel props might be higher, especially for large-scale construction projects. Additionally, the costs associated with regular maintenance and replacement might add up over time. 5. Limited load-bearing capacity: While steel props are designed to support heavy loads, they have a certain load-bearing capacity. Exceeding this capacity can lead to structural failures and accidents. Careful calculation and monitoring of loads are necessary to prevent overloading the props. 6. Safety concerns: Steel props, like any temporary support system, require proper installation and adjustment to ensure stability. Improper installation or inadequate bracing can result in collapses or accidents, posing risks to workers and the surrounding environment. 7. Aesthetics: Steel props may not be visually appealing, especially in finished or visible areas of a construction project. They can obstruct views and disrupt the overall aesthetic appeal of the structure until they are removed. Despite these potential drawbacks, steel props continue to be widely used in construction due to their strength, durability, and reliability. However, it is essential to carefully consider these drawbacks and assess whether alternative support systems might be more suitable for specific construction projects.

- Q: Can steel props be used in shoring applications?

- Yes, steel props can be used in shoring applications. Steel props, also known as adjustable steel props or steel shore posts, are commonly used in construction to provide temporary support and reinforcement to structures during renovation, repair, or construction activities. They are designed to be adjustable in height, allowing for customization and flexibility in shoring applications. Steel props are durable, strong, and reliable, making them suitable for various shoring needs in construction projects.

- Q: Can steel props be used for supporting prefabricated structures?

- Indeed, prefabricated structures can be supported using steel props. These adjustable and robust support systems are capable of offering either temporary or permanent support to a variety of structures, including prefabricated ones. Typically constructed from top-notch steel, these props are engineered to possess the necessary strength to uphold the weight of the structure they support. During the construction or installation of prefabricated structures, these props can be effortlessly adjusted and firmly secured in place to provide the required support. Consequently, steel props find extensive use in the construction sector, where they serve a multitude of purposes, including the support of prefabricated structures.

Send your message to us

Climbing Formwork- Formwork- Cantilever

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords