Climbing Formwork-Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

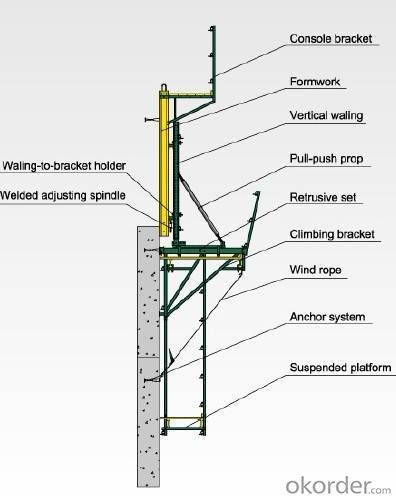

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on.

The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect.

Cantilever formwork has several types, the structure is similar, and has its own different characteristic.The client can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

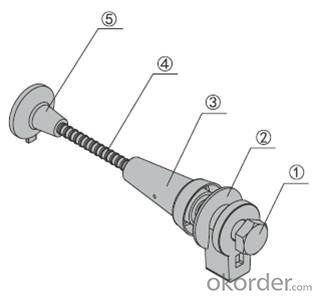

Anchor system

Anchor system is the most importantsupporting part. The system is made of five parts shown below. There into,tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusingafter the concrete pouring

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

We dedicated to the offer the whole formwork solutions to you, which includes the design, manufacture, sale and after-sale services. Please feel free to contact us if you have any requirement.

- Q: Can steel props be used for temporary support during ductwork installation?

- Yes, steel props can be used for temporary support during ductwork installation. Steel props are adjustable and sturdy, making them ideal for providing temporary support to hold ductwork in place during installation. They can be easily adjusted to the desired height and securely locked into position, ensuring stability and safety for the ductwork. Additionally, steel props are capable of bearing heavy loads, making them suitable for supporting the weight of ductwork and any associated equipment or materials. Overall, steel props offer a reliable and practical solution for temporary support during ductwork installation.

- Q: Are steel props adjustable in both height and width?

- No, steel props are typically only adjustable in height and not in width.

- Q: How do steel props compare to wooden shores in terms of durability?

- Steel props are generally more durable than wooden shores. Steel is a stronger and sturdier material compared to wood, which makes steel props more resistant to wear and tear. Steel props can withstand heavy loads and provide superior support, making them suitable for projects that require greater strength and stability. Unlike wood, steel is not susceptible to rot, decay, or termite damage, which significantly extends its lifespan. Steel props also have the advantage of being adjustable, allowing for precise height adjustments to accommodate different construction needs. While wooden shores may be more cost-effective initially, steel props offer a longer-lasting and more durable solution for construction and renovation projects.

- Q: Can steel props be used in residential construction projects?

- Residential construction projects can utilize steel props for vertical support. Steel props, also known as adjustable steel props or steel shores, are temporary supports that provide stability to structures during construction or renovation. They are commonly employed in residential construction to support load-bearing elements like beams and walls. Steel props are favored in construction due to their strength and adjustability. They can be easily modified to the desired height and offer stable support for heavy loads. Typically constructed from high-quality steel, they guarantee durability and the ability to withstand heavy loads. In residential construction, steel props can be utilized in various scenarios. For instance, they can support temporary beams during the installation of new windows or doors, reinforce walls during demolition or renovation, or uphold the weight of a temporary roof structure while constructing a new floor. Moreover, steel props are versatile and can be adjusted to fit different heights and angles, making them suitable for a wide range of applications in residential construction. Their quick installation and removal save time and effort during construction projects. Nevertheless, it is crucial to note that the use of steel props should be handled by professionals with the required knowledge and experience to ensure safe and proper installation. Improper utilization may result in accidents or structural failures, which can be hazardous and costly. In conclusion, steel props are an effective solution for temporary support in residential construction projects. Their strength, adjustability, and versatility make them a reliable choice for supporting various load-bearing elements. However, it is vital to ensure that qualified professionals install them correctly to guarantee safety and avoid potential risks.

- Q: Bearing 40 tons need much steel support

- 5, comprehensive classification(1) ordinary steelA. carbon structural steel: (a) Q195; (b) Q215 (A, B); (c) Q235 (A, B, C); (d) Q255 (A, B); (E).B. low alloy structural steelC. general purpose structural steel

- Q: How do you ensure proper stability of steel props on uneven surfaces?

- To ensure the proper stability of steel props on uneven surfaces, there are several important steps that need to be taken into consideration: 1. Take a thorough assessment of the uneven surface: Before setting up the steel props, it is crucial to carefully examine the uneven surface in order to gain a clear understanding of its nature and the degree of unevenness. It is important to identify any significant bumps, slopes, or irregularities that could potentially impact the stability of the props. 2. Opt for adjustable props: It is recommended to use adjustable steel props that can be extended or retracted as required. This will allow you to customize the height of the props to accommodate the uneven surface and maintain stability. 3. Ensure the props are level: Ensuring that the props are level on the uneven surface is of utmost importance. It is advisable to use a spirit level or laser level to check and adjust each prop individually. This will help evenly distribute the load and minimize the risk of the props tipping over. 4. Utilize base plates or sole boards: Placing base plates or sole boards under each prop can significantly enhance stability. These plates or boards should be sufficiently large to provide a solid foundation and prevent the props from sinking into soft or uneven ground. They also assist in distributing the load and reducing the likelihood of the props tilting. 5. Secure the props: To further increase stability, it is recommended to secure the props by using appropriate clamps or ties to connect them to the structure or adjacent props. This will prevent any lateral movement or potential collapse of the props. 6. Regularly inspect and make adjustments: It is important to periodically inspect the props throughout the duration of the work in order to ensure their stability. If any subsidence or movement is observed, it is crucial to promptly adjust the props or make necessary modifications to maintain stability. 7. Seek professional guidance: If there is any uncertainty regarding the stability of the steel props on uneven surfaces, it is advisable to consult with a structural engineer or construction professional. They can provide expert advice and recommend specific measures to ensure proper stability based on the unique characteristics of the surface and the load being supported.

- Q: What are the guidelines for the proper installation and removal of steel props?

- The guidelines for the proper installation and removal of steel props involve several key steps to ensure safety and effectiveness. Here are the general guidelines to follow: 1. Preparation: Before installation, assess the site conditions and ensure it is suitable for steel props. Check for any potential hazards or obstructions that may affect the installation process. 2. Selection of props: Choose the appropriate type and size of steel props based on the load-bearing requirements and the height of the structure being supported. Ensure the props are in good condition, free from any defects or damages. 3. Installation: Begin by placing the base plate of the steel prop onto a stable and level surface. Make sure the prop is vertical and aligned with the load-bearing point. Extend the prop to the desired height by adjusting the inner tube and secure it by tightening the locking pin or collar. 4. Load distribution: Ensure that the load is evenly distributed across the prop's base plate. Use timber or steel sole plates under the base plate if necessary to distribute the load over a larger area. This prevents excessive pressure on the ground or floor. 5. Bracing and stability: To enhance stability, use diagonal bracing or ties between the steel props and the supported structure. This helps prevent lateral movement or collapse in case of any unexpected forces. 6. Regular inspections: Monitor the steel props regularly during the installation process to identify any signs of instability, bending, or damage. If any issues are detected, take immediate action to rectify them or seek professional assistance. 7. Removal: When removing steel props, gradually reduce the load on each prop, taking care not to cause any sudden shifts or collapses. Loosen the locking pin or collar and lower the prop's inner tube slowly and steadily, ensuring a controlled descent. 8. Maintenance and storage: After removal, inspect the steel props for any damages or wear. Clean them thoroughly and store them in a dry and secure location to prevent rust or deterioration. Regularly maintain and service the steel props to prolong their lifespan. Remember, it is crucial to follow manufacturer guidelines and local regulations specific to your region when installing and removing steel props.

- Q: Can steel props be used in confined spaces?

- Yes, steel props can be used in confined spaces. Steel props are adjustable and versatile support systems commonly used in construction, renovation, and maintenance projects. They are designed to provide temporary support for structures, such as ceilings, walls, and beams, during construction or repair work. In confined spaces where there is limited access or restricted working conditions, steel props can be particularly useful. Due to their adjustable nature, they can be shortened or extended to fit the specific height requirements of the confined space. This allows for precise and controlled support, ensuring the safety and stability of the structure being worked on. Additionally, steel props are typically made of strong and durable materials, such as steel or aluminum, which can withstand heavy loads. This makes them suitable for use in confined spaces where there may be a need for extra support or load-bearing capacity. However, it is important to consider certain factors when using steel props in confined spaces. These include ensuring proper placement and alignment, regular inspections for any signs of damage or wear, and following safety guidelines and regulations. It is also crucial to have trained personnel who are experienced in working in confined spaces and in using steel props. Overall, steel props can be effectively used in confined spaces, providing the necessary support and stability required for construction and maintenance activities while adhering to safety standards.

- Q: Can steel props be customized for specific projects?

- Certainly! Steel props have the capability to be tailored to suit particular projects. These adjustable supports are employed in construction to offer temporary assistance to beams, slabs, walls, and other structures. They are accessible in diverse dimensions and configurations to accommodate varying project needs. In order to cater to specific project requirements, steel props can be personalized in terms of height, load-bearing capacity, and other specifications. This customization facilitates a perfect fit and optimum support, guaranteeing safety and efficiency during construction. Moreover, certain manufacturers provide made-to-order steel props that can be uniquely crafted to satisfy individual project needs, thereby offering even more flexibility and customization possibilities.

- Q: Are steel props suitable for use in the construction of shopping malls?

- Yes, steel props are suitable for use in the construction of shopping malls. Steel props, also known as adjustable steel columns or steel shores, are commonly used in construction to support and reinforce structures. They provide temporary support during the construction process and help distribute the weight of the building. Shopping malls are typically large buildings with multiple floors and heavy loads, including the weight of people, merchandise, and equipment. Steel props are strong, durable, and capable of withstanding heavy loads, making them ideal for supporting the various components of a shopping mall. In addition, steel props are adjustable, allowing for flexibility in height and alignment. This adjustability is particularly useful during the construction of shopping malls, as it allows for easy adaptation to different floor levels, changing construction requirements, and variations in load-bearing capacities. Furthermore, steel props are easy to install and dismantle, making them efficient and cost-effective for construction projects. They can be easily transported, assembled, and adjusted as needed, saving time and labor during the construction process. Overall, steel props are a suitable choice for use in the construction of shopping malls due to their strength, durability, adjustability, and overall efficiency. Their ability to support heavy loads and provide temporary structural support makes them an essential component in the construction industry.

Send your message to us

Climbing Formwork-Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords