Climbing Formwork- Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

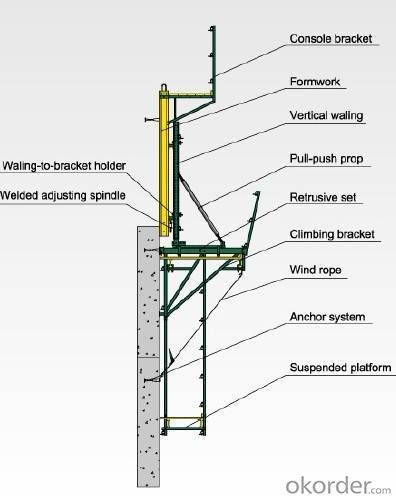

CantileverFormwork is mainly used in the concrete pouring of pier,high buildings, and so on. The concrete lateral pressure is entirely supportedby anchor system and the wall-through tie-rods, additional reinforcement is notneeded. The construction is easy, rapid and economical. A single pouring height is high and thefinished concrete surface is perfect. Cantilever formwork has several types,thestructure is similar, and has its own different characteristic.Canuse them according to actual demand.

Maincantilever Formwork:PJ200 & PJ240,CB-240 etc.

Anchor system

Anchor system is the most importantsupporting part. The system is made of five parts shown below. There into,tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusingafter the concrete pouring

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤ Ancor plate D15

- Q: Can steel props be used in the installation of temporary telecommunications infrastructure?

- Yes, steel props can be used in the installation of temporary telecommunications infrastructure. Steel props are commonly used as a support system for various construction projects, including the installation of temporary structures. They provide stability and structural support, making them suitable for the installation of temporary telecommunications infrastructure such as towers, antennas, or equipment shelters.

- Q: Can steel props be used for supporting temporary disaster relief shelters?

- Yes, steel props can be used for supporting temporary disaster relief shelters. Steel props are sturdy and can provide solid support to ensure the stability and safety of the shelters. They can withstand heavy loads and adverse weather conditions, making them suitable for temporary structures during disaster relief efforts.

- Q: How to reinforce the lower part of the steel structure of the construction elevator on the roof of the non - air defense garage

- On the basis of the natural foundation of the tower crane, you can balance the freedom of the height of the crane hoisting moment, a considerable weight. To 5 m X5 m X1.4 m tower base to calculate the weight of 84 tons.

- Q: How do you ensure the stability of steel props on soft or unstable ground?

- To ensure the stability of steel props on soft or unstable ground, there are several measures that can be taken: 1. Use a larger base plate: Increasing the size of the base plate that supports the steel props can help distribute the weight over a larger area, reducing the pressure on the soft or unstable ground. This can help prevent sinking or instability. 2. Provide additional support: If the ground is particularly soft or unstable, additional measures such as using timber sleepers or steel plates beneath the base plate can help provide extra support and stability. These materials can help distribute the load more evenly and prevent sinking or tilting. 3. Install ground anchors: Ground anchors can be used to secure the steel props and prevent them from shifting or sinking. These anchors are typically installed at an angle and are attached to the steel props, providing additional stability by anchoring them to deeper, more stable layers of soil or rock. 4. Consider using adjustable props: Adjustable steel props allow for easy and precise height adjustment, which can be beneficial when dealing with soft or unstable ground. By regularly monitoring and adjusting the props to maintain the desired height and stability, any potential issues can be addressed promptly. 5. Seek professional advice: If you are unsure about the stability of the ground or the appropriate measures to take, it is always recommended to consult with a professional engineer or structural expert. They can assess the specific site conditions and provide guidance on the most suitable methods to ensure stability and prevent any potential hazards.

- Q: Can steel props be used in renovation or remodeling projects?

- Certainly, renovation or remodeling projects can definitely utilize steel props. These props, also referred to as adjustable steel props or steel scaffolding props, serve the purpose of offering temporary support to walls, ceilings, or any other structural components while construction or renovation work is underway. They are commonly employed in situations where walls require demolition, openings need to be created, or structural modifications are taking place. Adaptable and flexible, steel props can be adjusted to different heights and lengths, rendering them suitable for a variety of renovation or remodeling tasks. Their primary function is to provide stability and support, ensuring the safety of workers and the overall structure. Moreover, steel props possess a high level of strength and durability, enabling them to withstand substantial loads and pressure. Throughout renovation or remodeling projects, steel props can be utilized to support walls or ceilings that are being removed or modified. They can also offer temporary support to floors or beams while structural changes are being implemented. By utilizing steel props, contractors can guarantee the stability and security of the structure throughout the renovation process. To conclude, steel props play a crucial role in renovation or remodeling projects, providing temporary support, stability, and safety during construction work. Hence, they are an ideal choice for various tasks, such as wall demolition, opening creation, or structural changes.

- Q: Are steel props adjustable in both horizontal and lateral directions?

- Yes, steel props are typically adjustable in both horizontal and lateral directions. Steel props, also known as adjustable steel props or adjustable steel shores, are commonly used in construction to support and stabilize structures. They are designed with a threaded mechanism that allows for easy adjustment of their height, making them suitable for various construction applications. In terms of adjustability in horizontal and lateral directions, steel props are typically equipped with swivel heads or base plates that allow for movement and alignment. The swivel head feature enables the prop to be adjusted horizontally, accommodating different angles or positions. Additionally, the base plate can be adjusted laterally to provide stability and support in various directions. The ability to adjust steel props in both horizontal and lateral directions is crucial in construction, as it allows for precise positioning and alignment of the props to support the load-bearing structure effectively. This adjustability ensures that the props can adapt to different construction scenarios and provide optimal support and stability. It is worth noting that the adjustability of steel props may vary depending on the specific design and manufacturer. Therefore, it is advisable to consult the manufacturer's instructions or specifications for each particular steel prop to ensure its adjustability in both horizontal and lateral directions.

- Q: Can steel props be used for temporary support in bridges?

- Steel props are capable of providing temporary support in bridges. During different stages of construction, including bridge construction, steel props are commonly utilized in construction projects to provide temporary support and stability to structures. These props are adjustable and can be effortlessly installed and removed, making them an optimal option for temporary support in bridges. By distributing the load and providing stability, steel props aid in the bridge structure's ability to sustain its own weight until it is fully completed. It is crucial, however, to guarantee that qualified professionals properly design and install the steel props to ensure the bridge's safety and stability during construction.

- Q: Can steel props be used in construction of airports?

- Yes, steel props can be used in the construction of airports. Steel props, also known as adjustable steel props or steel shoring props, are commonly used in construction projects to support vertical loads, provide temporary support, and ensure stability during construction activities. They are designed to be adjustable, allowing for easy installation and removal. In the construction of airports, steel props can be utilized in various applications. They can be used to support formwork systems during the construction of concrete structures such as terminals, hangars, control towers, and other airport buildings. Steel props provide temporary support to ensure the formwork remains stable and secure while the concrete is being poured and cured. Additionally, steel props can be used for temporary shoring during excavation and foundation works. They can support the weight of excavation walls and prevent soil collapse, ensuring the safety of workers and the stability of the construction site. Steel props can also be used to support scaffolding systems for maintenance and repair works in airport facilities. Steel props are highly versatile and can be adjusted to different heights and load capacities, making them suitable for various construction requirements in airports. They are known for their strength, durability, and ease of installation, making them a reliable choice for construction projects with strict safety standards, such as airports. It is important to consider the specific requirements and regulations of each airport construction project, as different airports may have unique design specifications and construction standards. Consulting with structural engineers and following local building codes and regulations will ensure the appropriate and safe use of steel props in airport construction projects.

- Q: Are steel props suitable for supporting temporary bridges or walkways over water bodies?

- Indeed, steel props prove to be a fitting choice when it comes to sustaining temporary bridges or walkways above water bodies. Demonstrating remarkable strength and durability, these props are capable of enduring substantial weights, rendering them an ideal support system for temporary structures like bridges or walkways. Ultimately, they offer stability and guarantee the safety of individuals or vehicles traversing over water bodies. Moreover, steel props possess the advantageous ability to be effortlessly adjusted and tailored to meet specific height or length prerequisites, thus showcasing their versatility in accommodating various types of temporary structures. All in all, steel props emerge as a dependable option for reinforcing temporary bridges or walkways above water bodies.

- Q: What are the common signs of wear or damage on steel props?

- Common signs of wear or damage on steel props include visible dents, cracks or bending, rust or corrosion, loose or damaged adjustment mechanisms, and excessive wear on the base plates or pins.

Send your message to us

Climbing Formwork- Cantilever Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords