Doka Formwork Singapore

Doka Formwork Singapore Related Searches

Doka Formwork System Formwork Singapore Doka Formwork Usa Doka Formwork Accessories Aluminium Formwork Singapore Doka Formwork Price List Peri Formwork Singapore Used Doka Formwork For Sale System Formwork Formwork System Aluminium Formwork Malaysia Meva Formwork Foundation Formwork Automatic Door Singapore Kumkang Aluminium Formwork Formwork Installation Flexible Ducting Singapore Fhs Formwork Kumkang Aluminium Formwork System Green Formwork Plastic Formwork Malaysia Formwork Props Striking Formwork Mfe Formwork India Conventional Formwork System Sian Formwork Moving Formwork Fabric Formwork Formwork Adalah Formwork WallDoka Formwork Singapore Supplier & Manufacturer from China

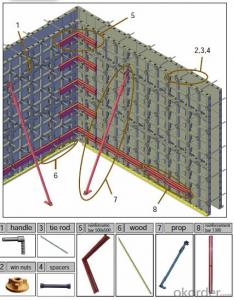

Doka Formwork Singapore is a comprehensive range of products designed to cater to the construction industry's needs, offering high-quality formwork systems, falsework, and accessories. These products are engineered to provide efficient, safe, and reliable solutions for various construction projects, including high-rise buildings, bridges, and tunnels. The advanced technology and innovative design of Doka Formwork Singapore products ensure that they meet the highest standards of performance and durability, making them a popular choice among construction professionals.The application and usage scenarios of Doka Formwork Singapore products are vast, as they are designed to accommodate a wide range of construction requirements. These products are commonly used in the construction of residential and commercial buildings, as well as in the development of infrastructure projects such as roads, railways, and airports. The versatility of Doka Formwork Singapore products allows them to be easily adapted to different project sizes and complexities, ensuring that they can be effectively utilized in various construction environments.

Okorder.com is a reputable wholesale supplier of Doka Formwork Singapore products, boasting a large inventory to cater to the diverse needs of the construction industry. As a leading supplier, Okorder.com is committed to providing customers with high-quality products at competitive prices, ensuring that they can access the necessary formwork solutions for their projects without compromising on quality or budget. By partnering with Okorder.com, customers can benefit from the convenience of a one-stop-shop for all their Doka Formwork Singapore needs, streamlining their procurement process and ensuring that they receive the best possible value for their investment.

Hot Products