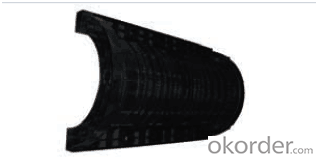

Plastic Concrete Formwork for Round Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

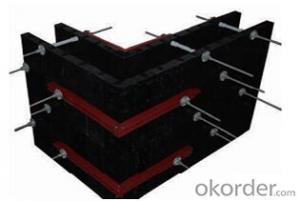

1. Structure of Plastic concrete formwork-Round panel

Plastic concrete formwork is more and more popular in the market. It consist of wall panel, corner panel, column panel, corner block and round panels. It is a very adjustable and flexible modular formwork and works quite efficiently.

The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures. So it could be made to be round panels as well.

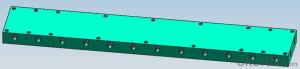

The normal size of column formwork is an30*75(H)*7(cm) and 40*75(H)*7(cm)

Both of them weight no less than 4.5kg and only use 8 handles to joint with other panels easily.

2. Main Features of Plastic concrete formwork-corner panel

-easy set up

-modularity work

-High strength

-enviroment friendly

-consequent

3. Plastic concrete formwork-Corner panel images

4. Plastic concrete formwork-Round panel Specifications

The normal size of column formwork is an30*75(H)*7(cm) and 40*75(H)*7(cm)

Both of them weight no less than 4.5kg and only use 8 handles to joint with other panels easily.

5. FAQ of Plastic concrete formwork-Round panel

1) What can we do for you?

.We can ensure the quality of Plastic concrete formwork-round panel and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- Solid can use foam technology to save costs, there is a hollow drawback in the use of the process, in the corner when the nail easily broken.

- Q: Why the floor is not plastic building materials square wood and template

- Not people do not have this product is not humane is not perfect not to buy only to be used to solve the trouble of the workers with the boss's doubts

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template construction is convenient, high efficiency: aluminum alloy building template system assembly is simple, convenient, average weight 30KG / m2, completely assembled by the artificial, do not need any mechanical equipment assistance (workers usually only need a wrench or a small hammer Easy to install), skilled installation workers can install 20-30 square meters per person per day (compared with the wooden mold: aluminum mold workers only need to install wood workers 70-80%, and do not need skilled workers, just install Before the construction of the staff can be a simple training can be).

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Why can not, now the plastic template, called light building materials, China is not yet a few plants can do a good job, after the air-conditioning refrigerator to use this, light and hard, not you like this, you can do with the wall, Now high-end are imported.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic construction template is not a good place to say, talk about the shortcomings of it, 1: the quality is too heavy, 2 intensity is not very satisfactory, 3, a little fee wooden side

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- Hardware stores have, any one hardware store can buy, you can buy the nearest.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- The quality of the template is related to the quality of concrete engineering. The key lies in the accurate size, the assembly is firm, the patchwork is tight and the assembly and disassembly is convenient. Should be based on the structure of the form and characteristics of the appropriate form of template, in order to achieve good technical and economic results.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- This does exist. The reason is that the plastic building template in the cut and fixed convenience, significantly weaker than the wooden building template, and in the demolition process, due to the brittleness of plastic, but also easy to break, and the cost of plastic template is too high, so the site Are generally willing to use wooden building templates. If you want to improve the number of wood construction template use, that is, cost, it is recommended that you choose building templates within 30 strong business

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Shear wall plastic template support: the wall height of 2800, wall thickness 300, for example, using 12mm template, vertical sub-rib spacing (center distance) for the 200-250mm; 15mm template, vertical sub-Leng spacing (center distance) For 250-300mm. Compared with the normal use of bamboo plywood template, the distance between the second time, the roughness of the concrete surface is basically the same, but the concrete surface smooth, to achieve the effect of water concrete, perception quality is better. To meet the requirements of cast-in-place concrete wall forming and surface quality. Construction template structure should be simple, light weight, durable, easy to manufacture.

Send your message to us

Plastic Concrete Formwork for Round Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords