Plastic Concrete Formwork for Column Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

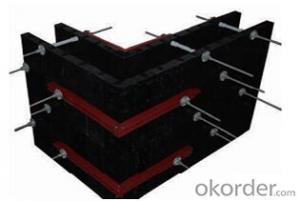

1. Structure of Plastic concrete formwork-Column panel

Plastic concrete formwork is more and more popular in the market. It consist of wall panel, corner panel, column panel, corner block and round panels. It is a very adjustable and flexible modular formwork and works quite efficiently.

The normal size of column formwork is 72*75(H)*7(cm) which weighes 8.8kg.

And it works with only 9 handles and easily set up with other panels.

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 1000px walls.

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment. Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

2. Main Features of Plastic concrete formwork-corner panel

-easy set up

-modularity work

-High strength

-enviroment friendly

-consequent

3. Plastic concrete formwork-Corner panel images

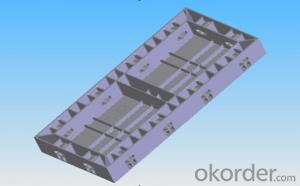

4. Plastic concrete formwork-Column panel Specifications

The normal size of column formwork is 72*75(H)*7(cm) which weighes 8.8kg.

And it works with only 9 handles and easily set up with other panels.

5. FAQ of Plastic concrete formwork-Column panel

1) What can we do for you?

.We can ensure the quality of Plastic concrete formwork-column panel and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- Personally feel that PVC sheet deformation has more reasons. The main reasons are as follows.Pvc plate deformation are: physical deformation and chemical deformation.1. Physical deformation, cause:High temperature lead to deformation, if it is such a deformation, targeted plastic raw materials for high temperature modification, can effectively improve such problems. Improper textile lead to deformation, such deformation has two reasons, a plate of raw materials can not meet the actual requirements of the product requirements, re-deployment of raw materials formula to meet the actual requirements of the product can be. Second, the processing and storage methods are not correct, leading to deformation, such problems can solve the problem from the root causes.2. Chemical deformation: mainly the molecular structure of raw materials change.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- It seems to have been the introduction of hollow plastic building template production line (foreign technology), the site last year to see someone used this plastic building template, our site is now using this plastic building template material is polypropylene PP, this template Cheap, suitable for ordinary wall. There is also a material that is made of polycarbonate PC This material is suitable for viaducts, water conservancy works, pouring walls without whitewashing. The wall is very light. It is expensive point.

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: Europe and the United States national construction template is made of plastic or wood

- Part of the place with stones, as the case may be, but certainly yes, Europe and the United States have anti-seismic buildings

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- Plastic mold is better, light weight, high impact strength, easy assembly, high turnover rate, smooth surface, no moisture, no mildew, Naisuan Jian, no cracking, large plate, less joints, can be saw, can Nail, can be processed into any length and so on

- Q: Types of building templates? What is the water template?

- With the development of the economy, the emergence of new materials in the building materials industry, the increasing number of types of building classification, there are four types of building templates

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- Hardware stores have, any one hardware store can buy, you can buy the nearest.

- Q: The price of raw materials can say better, is the PVC material.

- Usually in square meters. But whether by square meters or by weight count, but the process is different, but the results will be the same unit price. Off to know how much the cost of this product, how much profit. The cost of each product produced by the factory are not necessarily, of course, the profit is not the same. Cost is the material, management, plant rent, utilities, machine depreciation and other costs together, and now PVC materials have different grades, the specific price can be found on the Internet to see.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Plastic building template to be extended when the expansion joints: As the plastic building template than the steel mold, wood mold thermal expansion coefficient larger, morning and evening laying plastic template must be reserved for about 2 mm expansion joints (according to the size of the day the temperature difference ), No need to reserve the expansion of the slit at noon. The length of the nail is generally 1.5 inches to 2 inches is appropriate, not too long or too short.

Send your message to us

Plastic Concrete Formwork for Column Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords