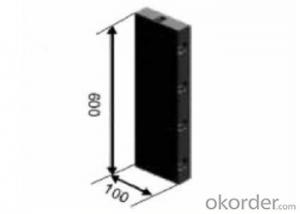

25 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Plastic Modular Formwork Panel:

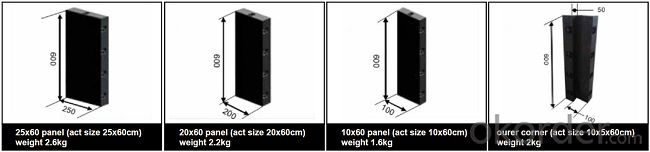

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x1500px, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x1500px), 20x60 panel (20x1500px),25x60 panel (25x1500px), inner corner (20x20x1500px) and outer corner (10x5x1500px). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x1500px) of multiple by 125px.

Using modular formwork, it is possible to pour up to 1000px thick and 3 meters high straight walls one time. Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be formed easily. The low weight and modularity of modular formwork makes it ideal for fence walls as it is possible to move large gang forms by hand.

2. Main Features of Plastic Modular Formwork Panel:

a. Easy Set Up

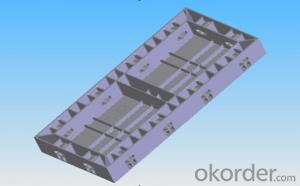

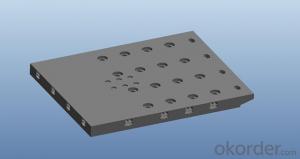

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

b. Modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x60cm) of multiple by 5cm.

c. Strength

The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures. The handles are made by high strength Nylon, each panel

locked by at least 4 handles, which makes the whole system strong enough to pour 40cm walls.

d. Environment Friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the environment.

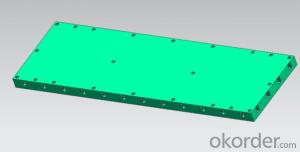

e. Consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

3. Plastic Modular Formwork Panel Images:

4. Plastic Modular Formwork Panel Specification:

5. FAQ of Plastic Modular Formwork Panel:

1) What promises can be done by us?

If interested in Plastic Modular Formwork, please feel free to write us for any QUOTE.

Please DO check goods when courier knocks your door and contact us asap if any issue.

2) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

Plastic Modular Formwork cost can be refund after order is confirmed.

If the products are not based on the requirements, there will be the relevant compensations made for you.

3) What about the package and shipping time?

Packing:As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Plastic Modular Formwork, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- The production of plastic building template not only has the many advantages of plastic template, but also successfully broke the plastic building template price is high, the price is equivalent to the current construction industry commonly used bamboo sheet, while giving the plastic template more advantage.

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Why can not, now the plastic template, called light building materials, China is not yet a few plants can do a good job, after the air-conditioning refrigerator to use this, light and hard, not you like this, you can do with the wall, Now high-end are imported.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic building template is an energy-saving and green products, is following the wood template, the combination of steel formwork, bamboo glued template, all the steel template after another new generation of products. Can completely replace the traditional steel formwork, wood template, square wood, energy saving and environmental protection, amortization cost is low.

- Q: Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- The general building materials market have to sell, I hope my answer can help you ~

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- Are generally wood board, plastic with less

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: The price of raw materials can say better, is the PVC material.

- General templates are fixed specifications, such as 1.22 * 2.44,980 * 2200 so it is generally in accordance with each template to price

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- The support system of the building template should be able to maintain the safety and reliability of the vertical placement of the building template and its own stability under the wind load. The length of the foot adjustment bolt should meet the need to adjust the vertical installation of the template and adjust the self-stabilizing angle. The foot adjustment device should be easy to adjust and turn flexible. Panel should be used not less than 5mm thickness of the production of steel, the material should not be lower than the performance requirements of Q215A, the template of the ribs and back corure should use steel, cold-formed thin-walled steel production, material and steel panel material should be the same brand to ensure Welding performance and structural properties. Panel system, support system, operating platform system and connectors and other components. Composition of the building template The connection between the various systems must be safe and reliable.

Send your message to us

25 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords