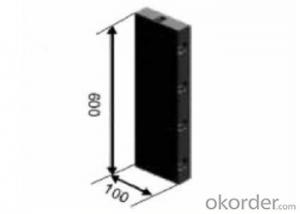

10 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

10 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

Description:

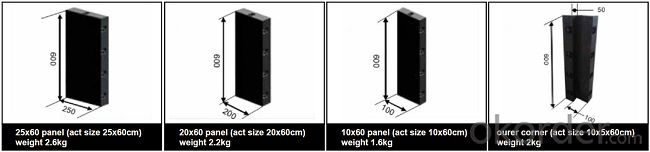

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm),25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x60cm) of multiple by 5cm.

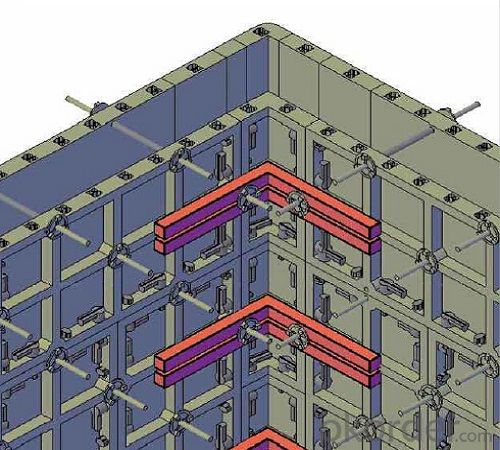

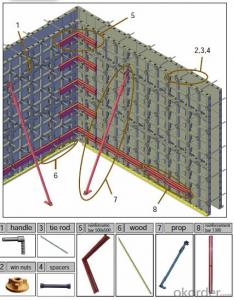

Walls and Corners

Using modular formwork, it is possible to pour up to 40cm thick and 3 meters high straight walls one time. Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be formed easily. The low weight and modularity of modular formwork makes it ideal for fence walls as it is possible to move large gang forms by hand.

Project Gallery

Advantages:

1. Easy Set Up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

2. Modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x60cm) of multiple by 5cm.

3. Strength

The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures. The handles are made by high strength Nylon, each panel

locked by at least 4 handles, which makes the whole system strong enough to pour 40cm walls.

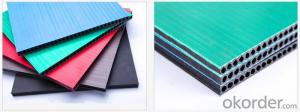

4. Environment Friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the environment.

5. Consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- This is not know your product materials and performance requirements, but the mold, then we generally use 45 steel, if the product is not corrosive strong, then what can be used to compare 50 steel.

- Q: Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Plastic construction template is the disadvantage of airtight and non-absorbent, in the mold, the wall will blister, can not meet the construction requirements, especially high-rise buildings, repeated use after a few times can no longer use. At present, a large number of domestic or wood template.

- Q: Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- The quality of the template is related to the quality of concrete engineering. The key lies in the accurate size, the assembly is firm, the patchwork is tight and the assembly and disassembly is convenient. Should be based on the structure of the form and characteristics of the appropriate form of template, in order to achieve good technical and economic results.

- Q: Plastic building template made of what material

- Building template is generally wood template, steel formwork, plastic template (also can be said that the composite template), steel plate high strength, can be reused many times

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- You can do that kind of ah! Raw materials are not easy to find

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Over the past two years the domestic market has appeared several "plastic building template", many builders are also trying to use plastic building templates, we all recognize that plastic building template is to replace steel mold, wood mold, bamboo mold of the inevitable product, Is the future direction of the development of architectural templates. Now the country has six or seven plastic building template manufacturers. Production of plastic building templates are different materials, in order to help all the correct selection of builders, the market is now on the composition of several plastic building templates and performance for a rough analysis, to all the use of plastic building templates to build a wake up , To avoid blind selection and cause unnecessary losses.

Send your message to us

10 X 60 mm Black Plastic Modular Formwork Panel for Straight Concrete Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords