120 X 60 Black Plastic Modular Concrete Wall Formwork Panel for Straight Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

| Material: | Plastic | Color: | Black |

| Type: | Wall Panel | Number Of Use: | 100 |

| Brand: | CMAX | Model: | CPANE0120 |

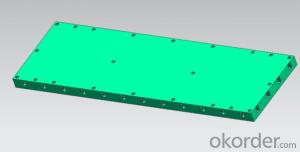

120 * 60 Black Plastic Modular Formwork Panel for Straight Concrete Wall

Description:

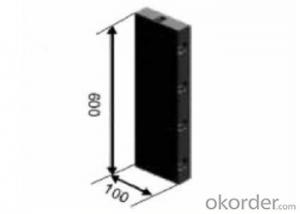

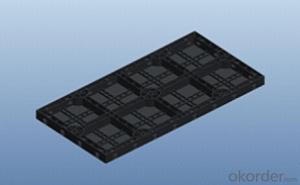

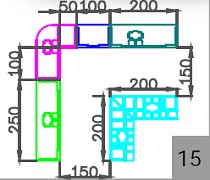

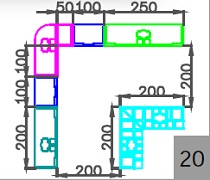

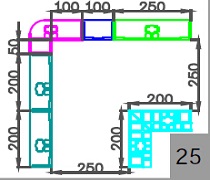

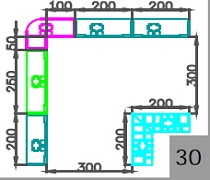

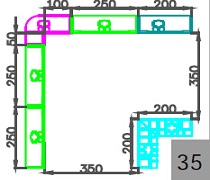

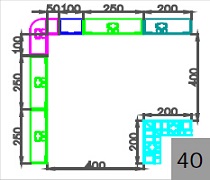

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm),25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x60cm) of multiple by 5cm.

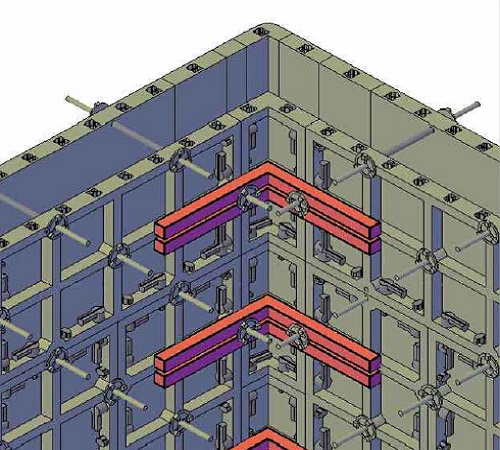

Walls and Corners

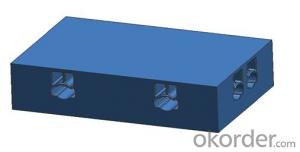

Using modular formwork, it is possible to pour up to 40cm thick and 3 meters high straight walls one time. Combining with special corners and compensation panels, right angle walls, three way T-walls and four way cross walls can be formed easily. The low weight and modularity of modular formwork makes it ideal for fence walls as it is possible to move large gang forms by hand.

Basins and Elevator Shafts

The low weight of modular formwork simplifies the pouring of tanks, basins and swimming pools in areas with limited or no access to heavy equipment. Modular formwork also ideal for elevator shafts as it can use without aid of crane, can make an easy, fast and precise job by hand.

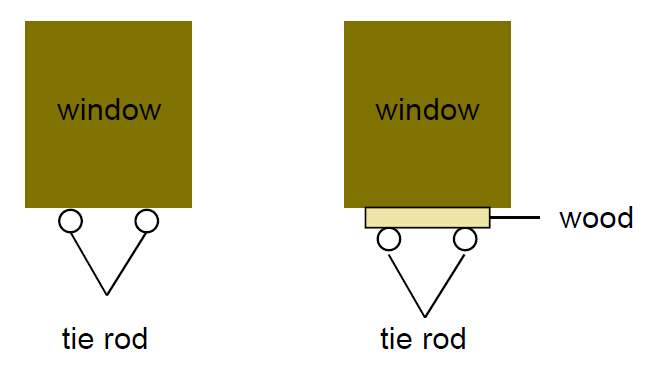

Doors and Windows

To make doors and windows by modular formwork is simple, by inserting inside the formwork a wooden frame corresponding to the size of the opening needed, and then pour the walls with doors and windows.

Corner Wall Configuration

Combined with outer corner, inner corner and appropriate size panels, modular formwork can make corner walls easily.

Advantages:

1. Easy Set Up

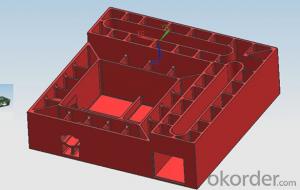

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

2. Modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls 120x60 panel (act size 120x60cm) of multiple by 5cm.

3. Strength

The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures. The handles are made by high strength Nylon, each panel

locked by at least 4 handles, which makes the whole system strong enough to pour 40cm walls.

4. Environment Friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the environment.

5. Consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- Solid can use foam technology to save costs, there is a hollow drawback in the use of the process, in the corner when the nail easily broken.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: Europe and the United States national construction template is made of plastic or wood

- With plastic construction, then, is the most solid touch on the back, Europe and the United States part of the country after the earthquake so the use of wood plus wire

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- The production of plastic building template not only has the many advantages of plastic template, but also successfully broke the plastic building template price is high, the price is equivalent to the current construction industry commonly used bamboo sheet, while giving the plastic template more advantage.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- With pliers slowly pull, or spray gun spray.

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- With PVC board and steel ceiling of the board on it, to the hardware store to buy

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: I heard that plastic construction template workers do not want to use, there is such a situation

- Are generally wood board, plastic with less

- Q: Plastic building template made of what material

- Template template, as the name implies, is a model (you can think so), and the building template is in the construction of the project, before making the actual product, according to the design pattern, according to the data, such as component dimensions and other related ghosts , To produce a model consistent with the design specifications, and the production of this model is the template material

- Q: The price of raw materials can say better, is the PVC material.

- Templates in accordance with the different prices of materials are also very different. The general plywood is 50-65 / sheet.

Send your message to us

120 X 60 Black Plastic Modular Concrete Wall Formwork Panel for Straight Wall

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords