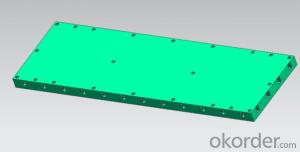

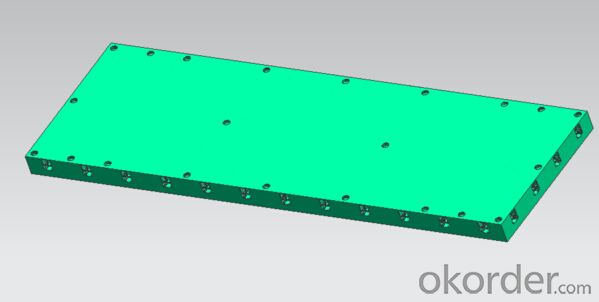

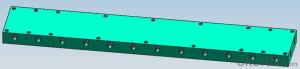

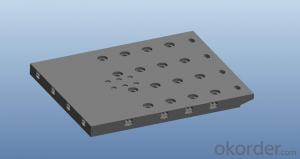

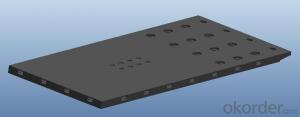

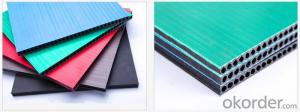

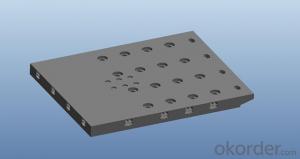

EANTE Square wall formwork 600×1800×80A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Haiyuan New Material possesses china’s first fully automatic long fiber reinforced thermoplastic composite mould pressing production line with independent intellectual property, referred to as LFT-D line.

Why we developed EANTE formwork?

Superiority:

General worker can assemble and remove easily, save more labor cost.

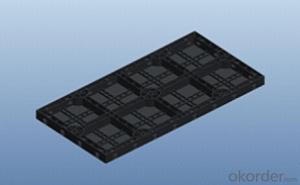

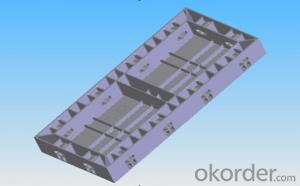

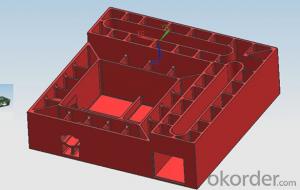

The reinforcing ribs of EANTE formwork can be used to instead of the steel tube and wood.

Preassemble the EANTE formwork in the factory and fix it in the construction location.

The size accuracy of the composite formwork is better than that of the steel formwork and the wooden formwork. The concrete surface cast by EANTE Formwork is quite smooth, without any flaw, and no release agent is applied to assist the formwork removing.

We developed our own software with the characteristics as follow:

a. Computation time: it depends on the complexity of the architecture drawing;

b. Construction drawing: it is shifted from assembling drawing easily;

c. Material list: the assembling designing software would generate a list of formwork elements and auxiliary products.

Enviromental: EANTE Formwork is made from composite material, which is low-carbon, recyclable and environment-friendly.

Saftness: The labor, large equipment, electric saws and iron nails are used much less on the building site, which leads to simplified on-site management and the safer construction.

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- This is not know your product materials and performance requirements, but the mold, then we generally use 45 steel, if the product is not corrosive strong, then what can be used to compare 50 steel.

- Q: Who used it, how not universal.

- The product has the following characteristics: 1. General product specifications 3020 * 1220 * (12-20) mm. Product area, construction joints less, improve the construction speed and efficiency. 2. The product can be sawed, planing, can be nailed, can be repaired, processing is very convenient. 3. Strong plastic PP plastic template does not absorb water, there is no stratification, cracking phenomenon.

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: The price of raw materials can say better, is the PVC material.

- General templates are fixed specifications, such as 1.22 * 2.44,980 * 2200 so it is generally in accordance with each template to price

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Easy to use, heat insulation. A lot of building materials market there ah, to see what you want the model, the price range,

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Shear wall plastic template support: the wall height of 2800, wall thickness 300, for example, using 12mm template, vertical sub-rib spacing (center distance) for the 200-250mm; 15mm template, vertical sub-Leng spacing (center distance) For 250-300mm. Compared with the normal use of bamboo plywood template, the distance between the second time, the roughness of the concrete surface is basically the same, but the concrete surface smooth, to achieve the effect of water concrete, perception quality is better. To meet the requirements of cast-in-place concrete wall forming and surface quality. Construction template structure should be simple, light weight, durable, easy to manufacture.

Send your message to us

EANTE Square wall formwork 600×1800×80A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords