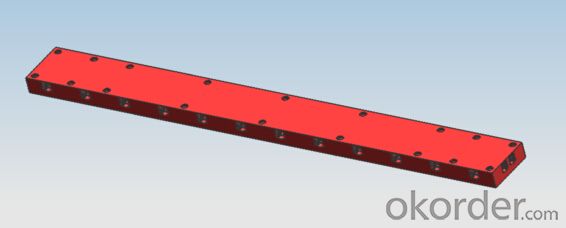

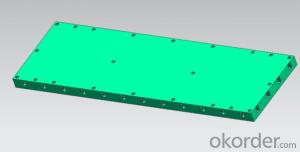

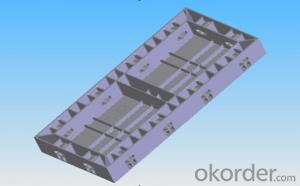

EANTE Square wall formwork 200×1800×80A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Haiyuan New Material possesses china’s first fully automatic long fiber reinforced thermoplastic composite mould pressing production line with independent intellectual property, referred to as LFT-D line.

Why we developed EANTE formwork?

Superiority:

General worker can assemble and remove easily, save more labor cost.

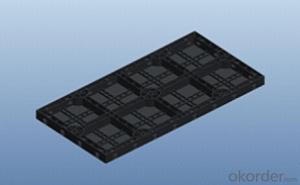

The reinforcing ribs of EANTE formwork can be used to instead of the steel tube and wood.

Preassemble the EANTE formwork in the factory and fix it in the construction location.

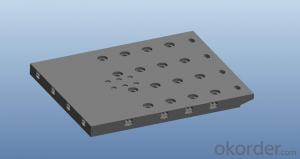

The size accuracy of the composite formwork is better than that of the steel formwork and the wooden formwork. The concrete surface cast by EANTE Formwork is quite smooth, without any flaw, and no release agent is applied to assist the formwork removing.

We developed our own software with the characteristics as follow:

a. Computation time: it depends on the complexity of the architecture drawing;

b. Construction drawing: it is shifted from assembling drawing easily;

c. Material list: the assembling designing software would generate a list of formwork elements and auxiliary products.

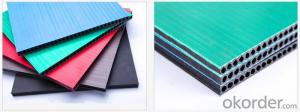

Enviromental: EANTE Formwork is made from composite material, which is low-carbon, recyclable and environment-friendly.

Saftness: The labor, large equipment, electric saws and iron nails are used much less on the building site, which leads to simplified on-site management and the safer construction.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q: Why the floor is not plastic building materials square wood and template

- Must be strong and durable, the environment is bad, need to find strong

- Q: Who used it, how not universal.

- 4. The product pouring concrete surface smooth, bright as a mirror, to meet the requirements of decorative and decorative water, eliminating the need for secondary plastering process. 5. Turnover times more than 50 times, the template each time the amortization cost is less than 3 yuan, steel frame plastic template turnover times more than 300 6. The material is non-toxic, harmless, pollution-free, 100% recovery, green products The 7. The product acid, alkali, anti-corrosion performance. Product use temperature of -80 ℃ ~ 100 ℃, good weather resistance.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- To be honest, not very good. The Temporary use can be

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- The main advantages are:1, the surface smooth and smooth, high strength, the provincial workers, the expected material, can meet the requirements of clear water concrete template, after stripping without cleaning the surface of the template, thus saving a lot of labor, template flatness can be controlled within 0.3mm, thickness uniformity, Can be controlled within ± 0.3mm, wood than the wood to save 2/3 of the nails.2, good water resistance, toughness, long-term immersion is not layered, water swelling rate of less than 0.06%, in -30 ℃ _ +60 ℃ range of normal use, the use of 6 years of aging of 15%, normal use of 8 Years or more.3, plasticity, according to the design and component size requirements, processing and production of different shapes and different specifications of the template, a curvature of the template for the production of a more simple template can be drilling nails, saws, planing and other wood mold with the same machinability , On-site stitching simple and convenient.4, recyclable use, plastic template to a certain extent can be fully recycled, regardless of the size of the old and new, after processing, can be added to produce a new template

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: Plastic building template where there is an urgent need to solve

- Plastic construction template turnover can reach more than 30 times, but also recycling. Temperature to adapt to a large range of specifications adaptability, can be saw, drill, easy to use. Temporal surface of the template, smoothness than the existing technical requirements of the water concrete template, a flame retardant, anti-corrosion, anti-water and anti-chemical corrosion function, have better mechanical properties and electrical insulation properties. Can meet a variety of cuboid, cube, L-shaped, U-shaped building support model requirements.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- This size is an international common size. Because more foreign use of foot units, 1 foot = 30.5cm, 1830 × 915 is usually said that the three or six feet board.

Send your message to us

EANTE Square wall formwork 200×1800×80A

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords